Bimetallic composite material with open 3D structure and preparation method and application thereof

A composite material and bimetal technology, which is applied in the field of bimetallic composite materials with open 3D structure and their preparation, can solve the problems of large volume effect and poor stability, and achieve the effect of good electrochemical performance and large application potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1: Dissolve 1.32g 2-methylimidazole in a mixed solution of 40mL absolute ethanol and water (v / v=1:1), and 2mmol (0.582g) Ni(NO 3 ) 2 ·6H 2 O was dissolved in the above solution, stirred at room temperature for 30 min until the solution turned yellow-green, and stood at room temperature for 24 h. The prepared yellow precipitate was washed with absolute ethanol several times to ensure that all ions not involved in the coordination were removed, and the product was centrifuged at a high speed of 10,000r / min, and the centrifuged material was placed in a vacuum oven at 70°C for drying. After 24h, the final product was collected for use in the next step.

[0031] Step 2: Grind the Ni-MOF prepared in the previous step into powder, weigh 0.23g and dissolve it in 30mL of absolute ethanol solution, in which 0.05g of SnCl was dissolved in advance 2 2H 2 O, after stirring at room temperature for 30min, the mixture was transferred to a polytetrafluoroethylene-lined reactor ...

Embodiment 2

[0035] With embodiment 1 step 2) in SnCl 2 2H 2 The amount of O was changed to 0.1g, and other conditions remained unchanged.

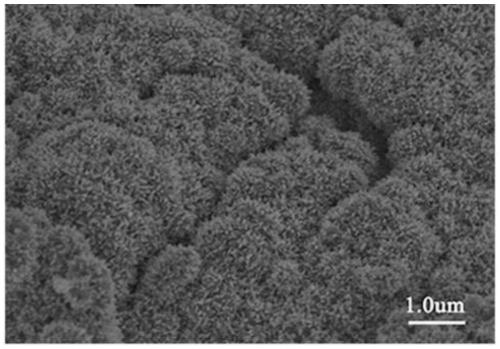

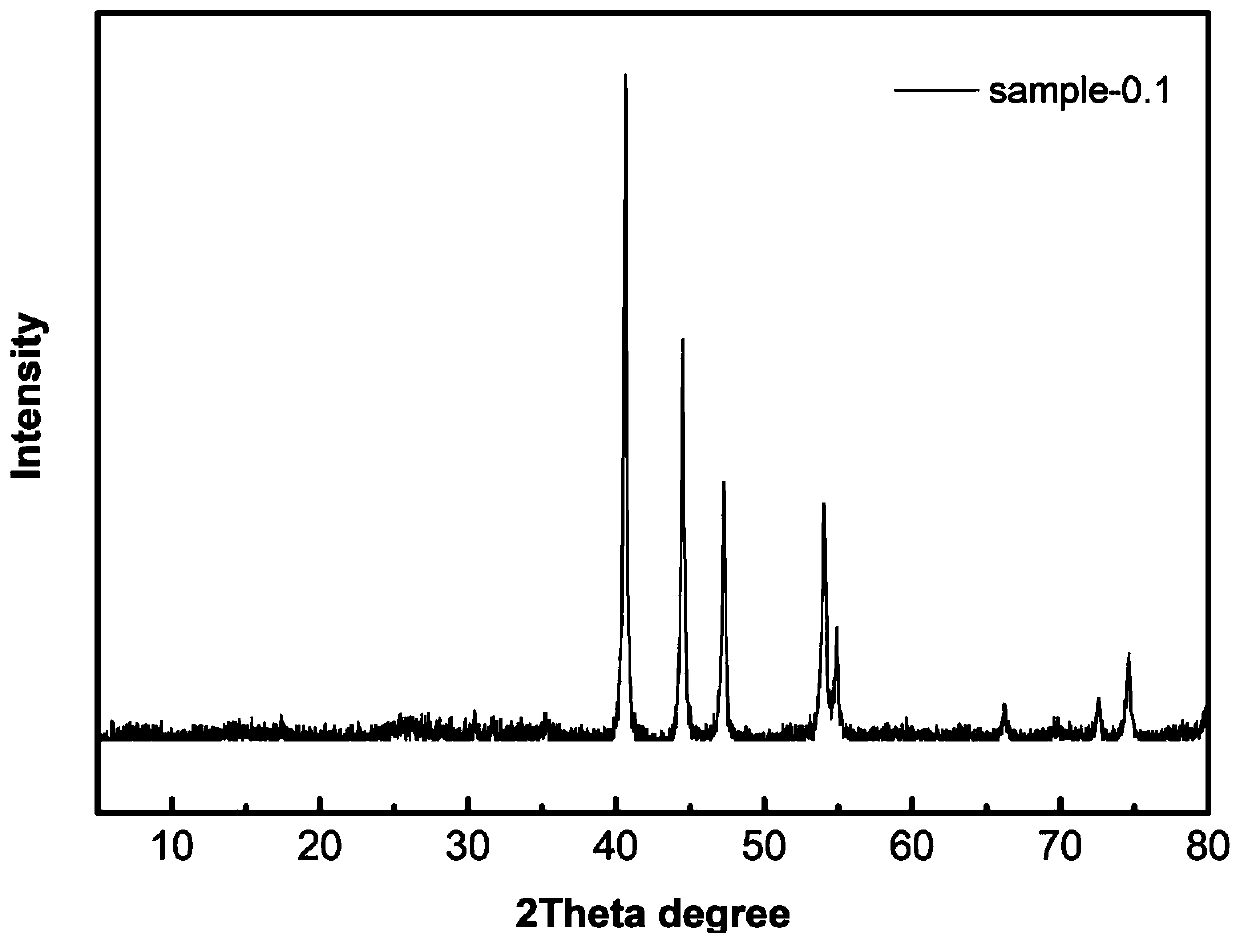

[0036] By testing the XRD of the product, it can be seen that the obtained black powder is Sn@Ni 2P / C, through the scanning electron microscope observation, the composite material presents an irregular flower-like structure, the size is about 1um, the irregular flowers are gathered together, and the surface is composed of a large number of small spines

Embodiment 3

[0038] With embodiment 1 step 2) in SnCl 2 2H 2 The amount of O was changed to 0.15g, and other conditions remained unchanged.

[0039] By testing the XRD of the product, it can be seen that the obtained black powder is Sn@Ni 2 P / C, observed by scanning electron microscope, the composite material presents an obvious rod-like structure. With the increase of Sn content, the rod structure is more obvious and larger in size, and even agglomerated structure appears.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com