A kind of titanium-based active bone implant with composite coating and preparation method thereof

A composite coating and bone implant technology, applied in coating, metal material coating process, prosthesis, etc., can solve the problems of limited research on MSCs recruitment strategy, overcome the shortage of MSCs, promote the formation of new bone, improve The effect of biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

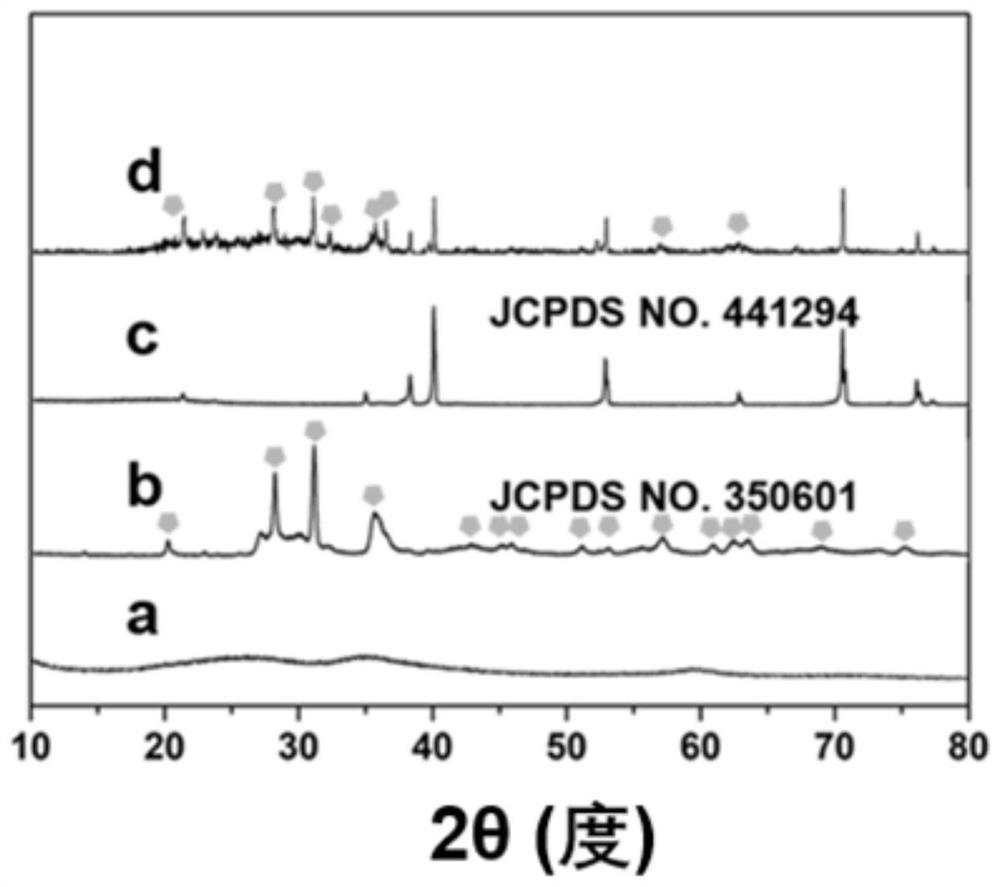

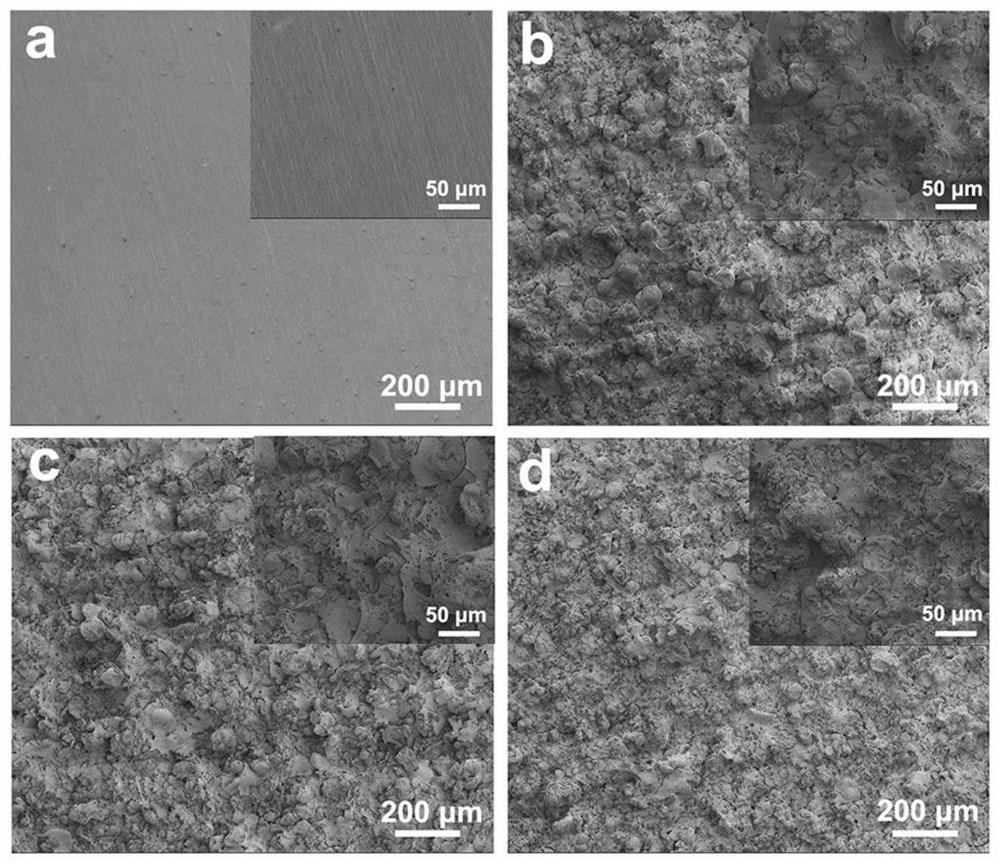

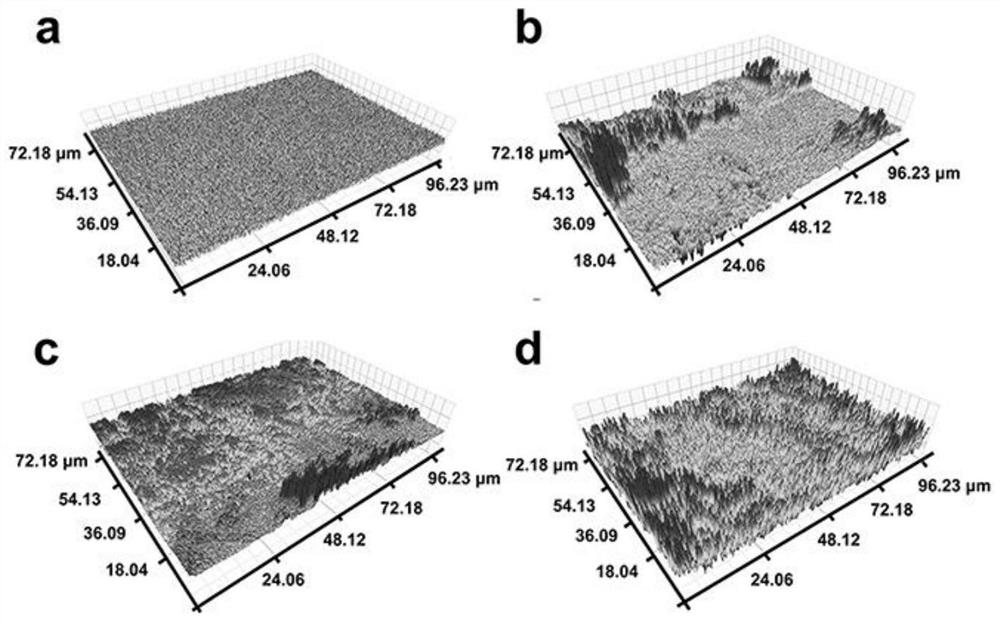

[0039] Fabrication of titanium-based active bone implants with composite coatings

[0040] (1) Add an equimolar amount of Na 2 SiO 3 9H 2 O and Mg(NO 3 ) 2 ·6H 2 After O was dissolved in water respectively, the Mg(NO 3 ) 2 ·6H 2 O solution into Na 2 SiO 3 9H 2 In the O solution, a milky white substance appears, continue to stir for 10 hours and then stand still for 16 hours, alternately filter and wash with ethanol and water for 3 times, then freeze-dry, calcined at 1000°C for 2 hours, grind, and sieve through a 250-mesh sieve to obtain MgSiO 3 micron particles;

[0041] (2) Ultrasonic cleaning of pure titanium with washing powder water, alcohol, deionized water, and alcohol for 15 minutes each, and drying for later use;

[0042] (3) Plasma spraying step (1) on the pure titanium surface treated by step (2) to obtain MgSiO 3 micron particles to obtain MgSiO with a thickness of 90 μm 3 bioceramic layer, followed by MgSiO 3 On the bioceramic layer, spin-coat chitos...

Embodiment 2

[0044] Fabrication of titanium-based active bone implants with composite coatings

[0045] (1) Add an equimolar amount of Na 2 SiO 3 9H 2 O and Mg(NO 3 ) 2 ·6H 2 After O was dissolved in water respectively, the Mg(NO 3 ) 2 ·6H 2 O solution into Na 2 SiO 3 9H 2 In the O solution, a milky white substance appeared, continued to stir for 12 hours, then stood still for 24 hours, alternately filtered and washed with ethanol and water for 4 times, then freeze-dried, calcined at 1200°C for 2 hours, ground, and sieved through a 250-mesh sieve to obtain MgSiO 3 micron particles;

[0046] (2) Ultrasonic cleaning of pure titanium with washing powder water, alcohol, deionized water, and alcohol for 15 minutes each, and drying for later use;

[0047] (3) Plasma spraying step (1) on the pure titanium surface treated by step (2) to obtain MgSiO 3 micron particles to obtain MgSiO with a thickness of 100 μm 3 bioceramic layer, followed by MgSiO 3 On the bioceramic layer, spin-coa...

Embodiment 3

[0049] Fabrication of titanium-based active bone implants with composite coatings

[0050] (1) Add an equimolar amount of Na 2 SiO 3 9H 2 O and Mg(NO 3 ) 2 ·6H 2 After O was dissolved in water respectively, the Mg(NO 3 ) 2 ·6H 2 O solution into Na 2 SiO 3 9H 2 In the O solution, a milky white substance appears, continue to stir for 8 hours and then stand still for 12 hours, alternately filter and wash with ethanol and water for 5 times, then freeze-dry, calcined at 800°C for 3 hours, grind, and sieve through a 250-mesh sieve to obtain MgSiO 3 micron particles;

[0051] (2) Ultrasonic cleaning of pure titanium with washing powder water, alcohol, deionized water, and alcohol for 15 minutes each, and drying for later use;

[0052] (3) Plasma spraying step (1) on the pure titanium surface treated by step (2) to obtain MgSiO 3 Micron particles, to obtain MgSiO with a thickness of 95 μm 3 bioceramic layer, followed by MgSiO 3On the bioceramic layer, spin-coat chitosan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com