Novel composite collecting agent for recovering zinc oxide from peat slate lead-zinc oxide ore and preparation method and application thereof

A composite collector, lead-zinc oxide technology, applied in the direction of solid separation, flotation, etc., can solve the difficult to achieve efficient recycling of zinc oxide minerals, low grade and recovery rate of zinc oxide concentrate, poor collection capacity and selectivity and other problems, to achieve the effects of saving manpower and material resources, improving flotation recovery rate and grade, good selectivity and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: In this embodiment, an oxidized lead-zinc ore containing peaty slate in a lead-zinc mine in Sichuan is used as the application object, and the oxidation rate of lead and zinc in the lead-zinc ore is greater than 35%. The flotation process is completed under laboratory conditions, and tap water is used as the water for flotation in the flotation process.

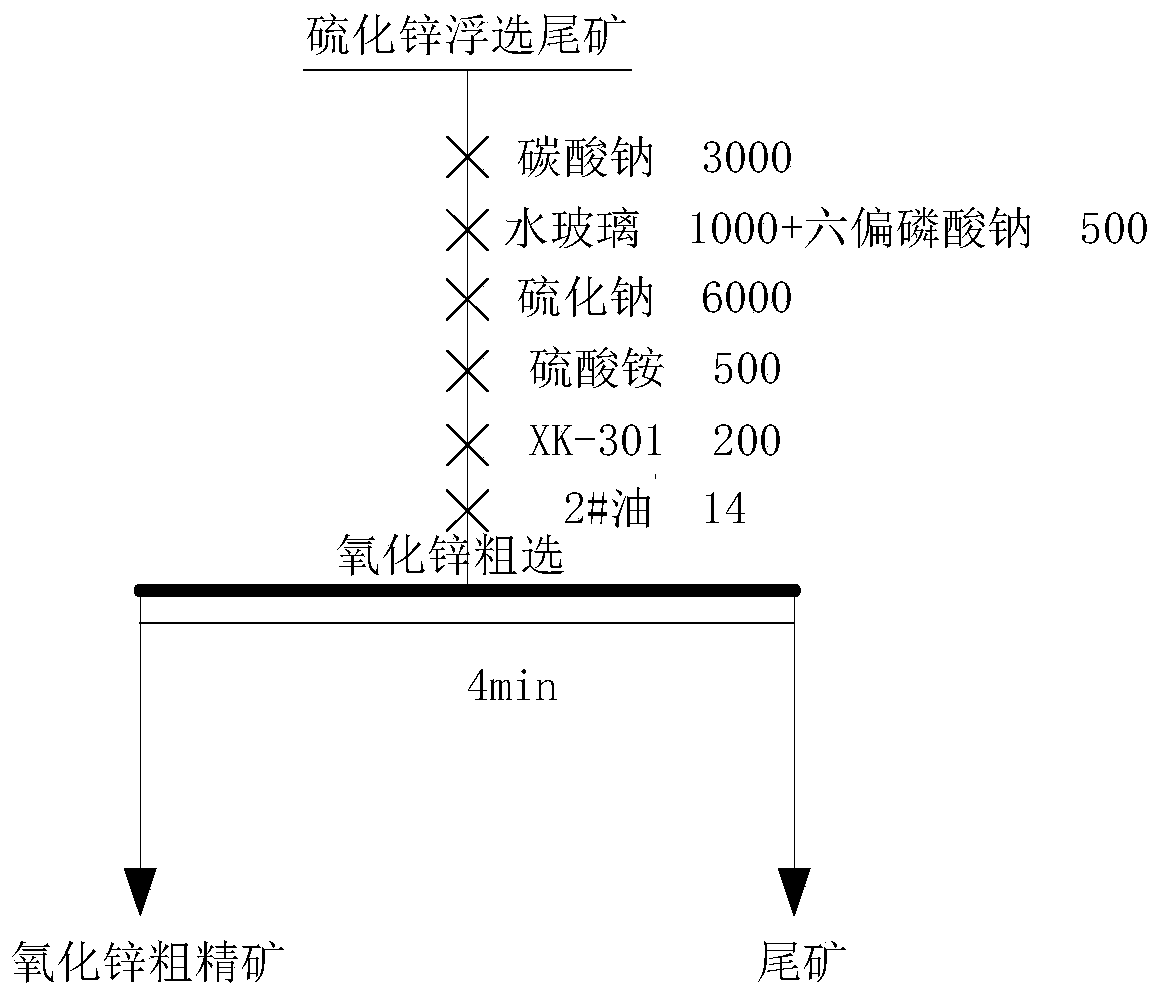

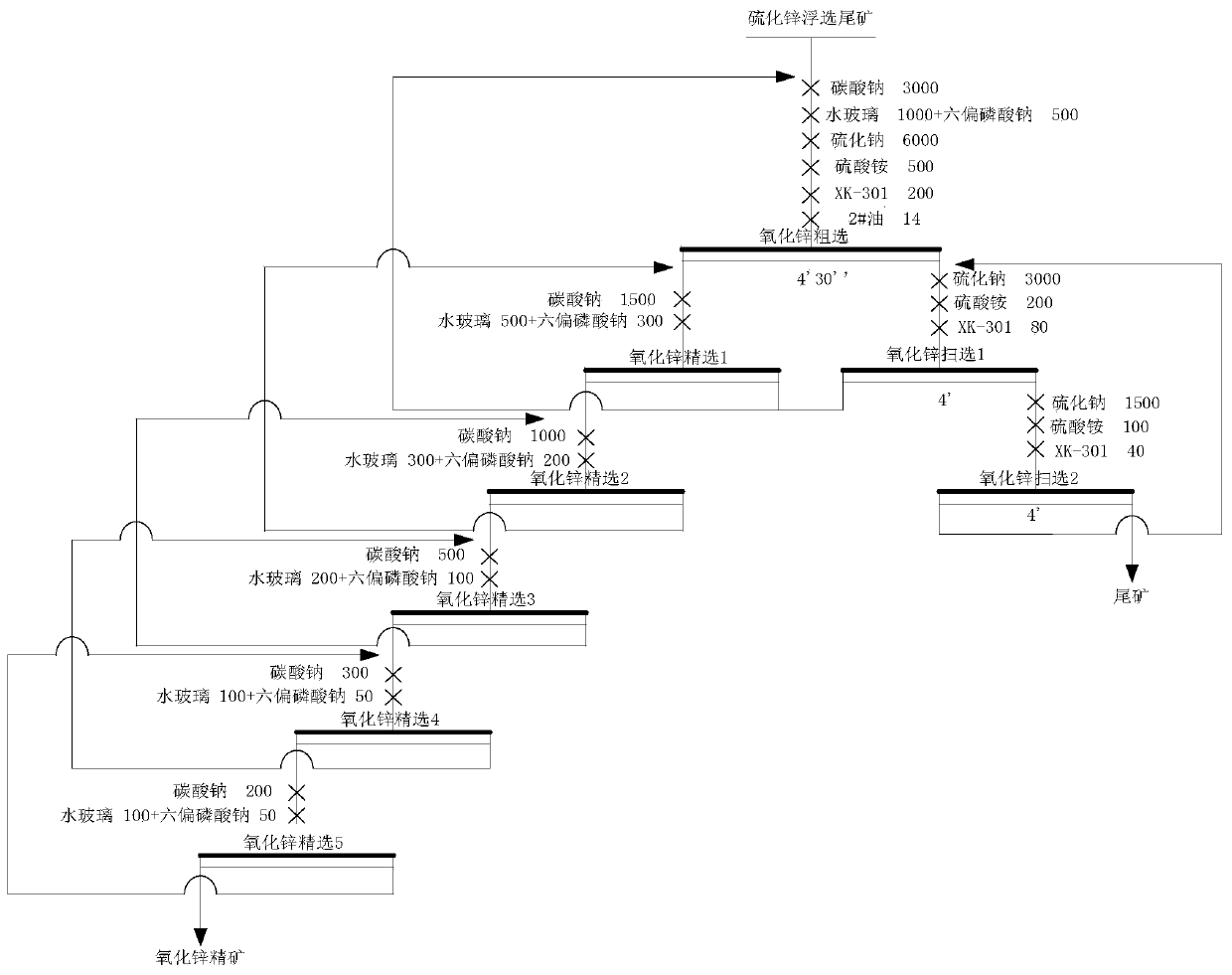

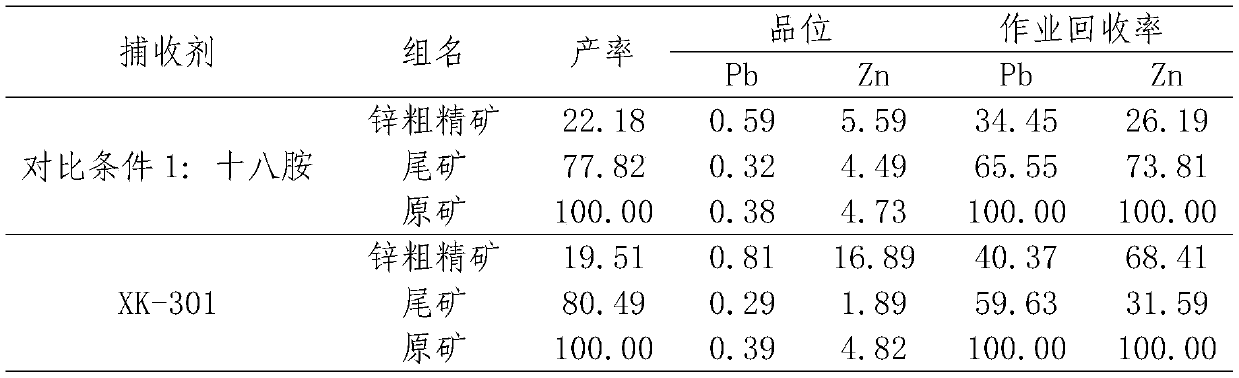

[0024] This embodiment is a comparative test of the effects of different collectors, and the test process is strictly in accordance with figure 1 The process shown is carried out. Weigh 1000g of the sample, and grind it for 7.5 minutes at a slurry concentration of 62.5% so that the proportion of mineral particles <200 mesh is 65%, carry out flotation experiments, and use the tailings of zinc sulfide minerals as the zinc oxide mineral selection operation to mine. Stir the ore slurry in the XFD 3L flotation tank for 2 minutes, then add regulator, activator, collector and foaming agent in turn, and stir fo...

Embodiment 2

[0031] Embodiment 2: In this embodiment, the oxidized lead-zinc ore containing peaty slate in a lead-zinc mine in Sichuan is used as the application object, and the oxidation rate of lead and zinc in the lead-zinc ore is greater than 35%. The flotation process is completed under laboratory conditions, and tap water is used as the water for flotation in the flotation process.

[0032] This embodiment is a comparative test of the effects of different collectors, and the test process is strictly in accordance with figure 1 In the flotation process shown, 1000g of the sample is weighed, and the ore is ground for 7.5 minutes at a pulp concentration of 62.5% so that the proportion of mineral particles <200 mesh is 65%. The flotation experiment is carried out, and the tailings of zinc sulfide minerals are used as The ore selection of zinc oxide mineral operation. Stir the ore slurry in the XFD 3L flotation tank for 2 minutes, then add regulator, activator, collector and foaming agen...

Embodiment 3

[0039] Embodiment 3: In this embodiment, the oxidized lead-zinc ore containing peaty slate in a lead-zinc mine in Sichuan is used as the application object, and the oxidation rate of lead and zinc in the lead-zinc ore is greater than 35%. The flotation process is completed under laboratory conditions, and tap water is used as the water for flotation in the flotation process.

[0040] This embodiment is a comparative test of the effects of different collectors, and the test process is strictly in accordance with figure 1 Carry out the flow shown, weigh 1000g of the sample, grind the ore for 7.5min at a slurry concentration of 62.5% to make the proportion of mineral particles < 200 mesh 65%, carry out the flotation experiment, and use the tailings of zinc sulfide minerals as this Mineral feed for zinc oxide mineral operations. Stir the ore slurry in the XFD 3L flotation tank for 2 minutes, then add regulator, activator, collector and foaming agent in turn, and stir for 3 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com