Small micro-bubble generator and method

A micro-bubble generator, a small technology, applied in the direction of ships, hydrodynamic characteristics/hydrostatic characteristics, hulls, etc., can solve the problems of high energy consumption, complex equipment, large equipment volume, etc., to achieve a simple and convenient control loop. The next time you use it, the device is small in size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

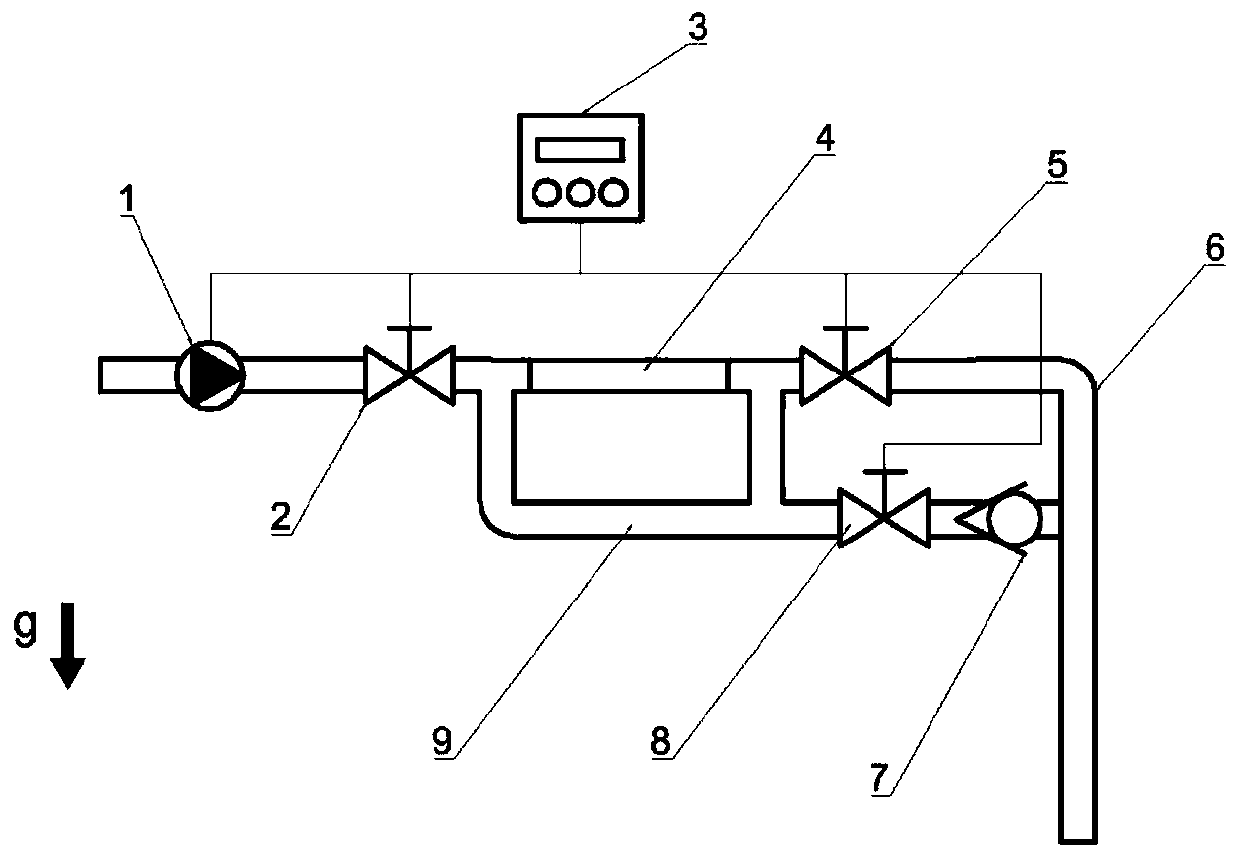

[0029] This embodiment is a small micro-bubble generating device. It is mainly composed of a water pump, a valve, a controller, a bubble generating chamber, a first pipeline, a second pipeline and a one-way valve. The role of the controller is to control the switch of the water pump and drive the servo motor to change the state of the bubble generating chamber.

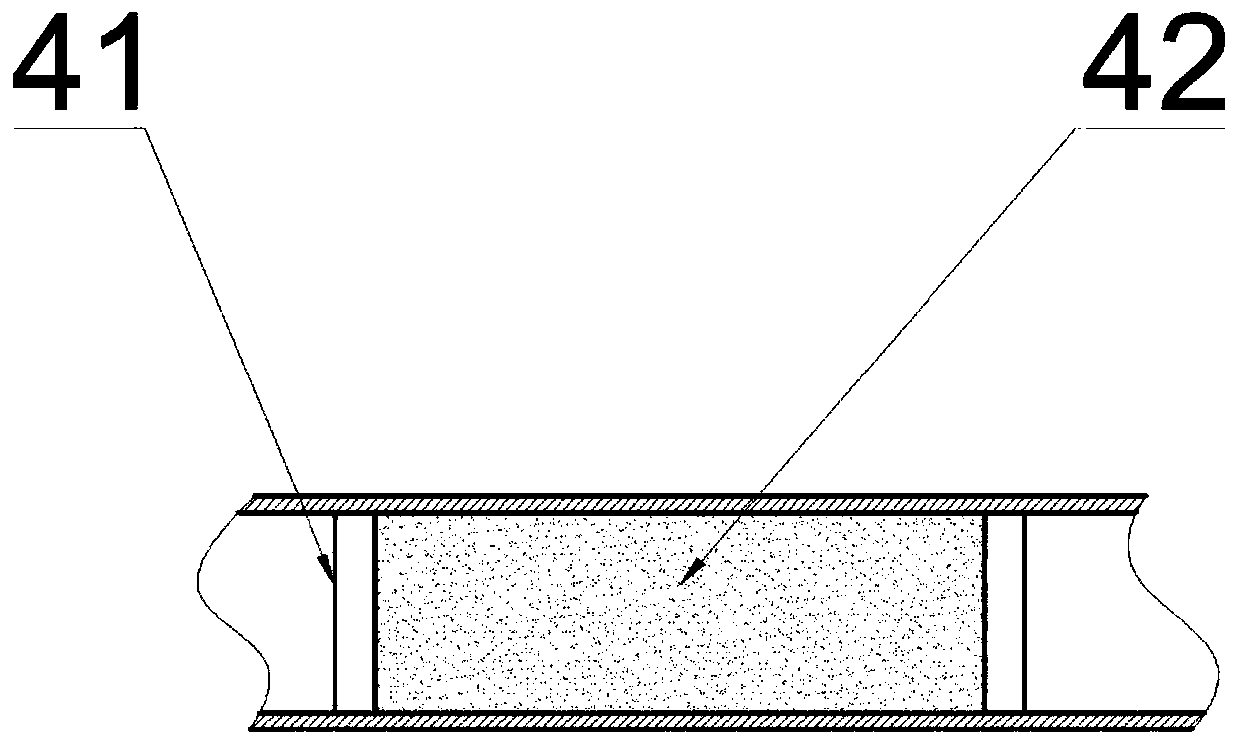

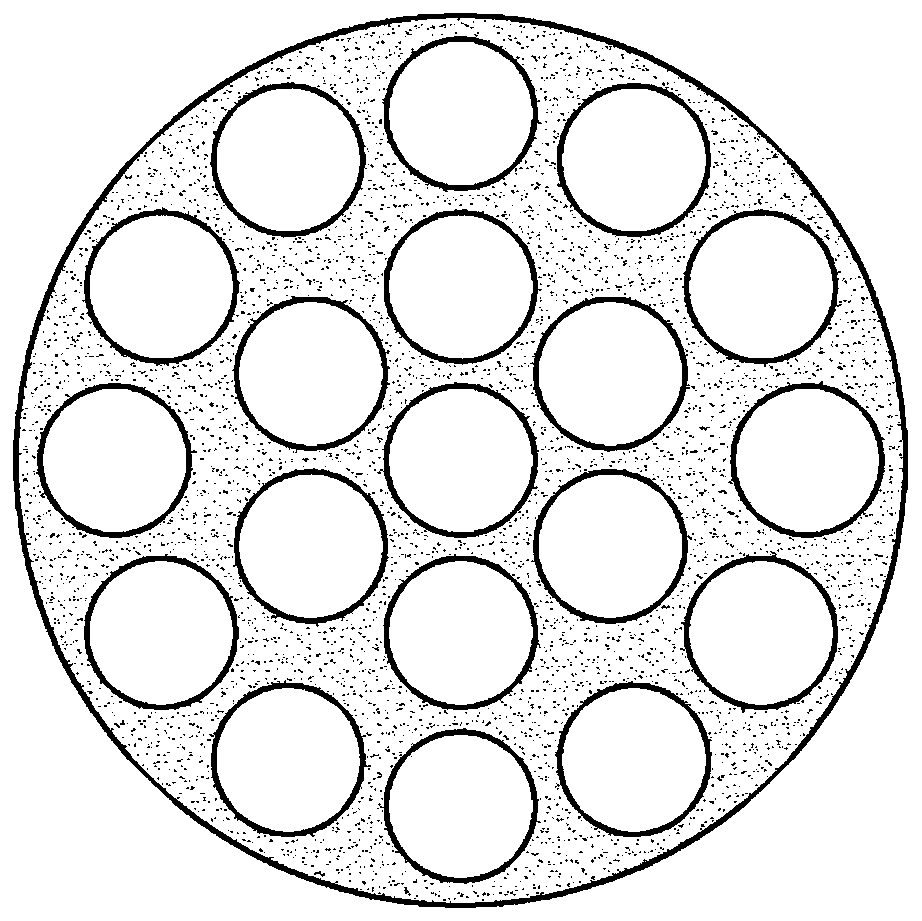

[0030] refer to figure 1 , figure 2 , image 3 . The water pump 1 is installed at the front end of the first pipeline 6 , and the bubble generating chamber 4 is installed at the middle section of the first pipeline 6 . There is a filter box 41 in the bubble generation chamber 4, and the solid reaction raw material block 42 is housed in the filter box 41. The solid reaction raw material block 42 is mainly formed by press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com