Dried cellulose fibers, cellulose fiber-resin composite, and molded article

A technology of cellulose fiber and dry body, which is applied in the field of cellulose fiber dry body, can solve problems such as difficulty and shrinkage, and achieve the effect of improving physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0122] Using cotton derived from cotton as the raw cellulose, an aqueous dispersion of cellulose fibers was produced.

[0123] First, cotton is pulverized with a cutter (Pulverisette 15 manufactured by Fritsch) to obtain cotton powder-like cellulose. The obtained cotton powdery cellulose was made into a concentration of 10% by mass, and a dispersion was prepared from ion-exchanged water, and subjected to 10 defibrillation treatments with a wet micronization device (manufactured by Sugino Machinery Co., Ltd., device name: Starburst) , Decompose fiber. After that, the ratio of the hemicellulose component in the constituent sugar of the cellulose fiber was measured by the analysis of constituent sugars. In addition, after freeze-drying the obtained aqueous cellulose fiber dispersion to obtain a dry powder sample, the average molecular weight thereof was determined by the viscosity method, and the presence or absence of cellulose type I crystals was confirmed by X-ray diffraction me...

manufacture example 2

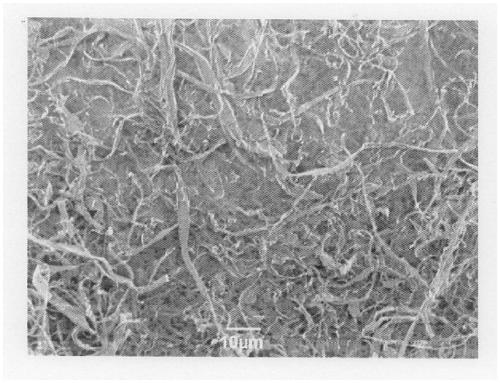

[0130] Do not add condensed ricinoleic acid ester (trade name: CRS-75, manufacturer: Sakamoto Pharmaceutical Industry) as a surfactant to the 10% by mass aqueous dispersion of cellulose fibers obtained in the same manner as in Production Example 1. Heat drying was performed in the same manner as in Example 1 to obtain a granular dried body. Furthermore, in the same manner as in Production Example 1, a pin mill was used for pulverization to obtain a dried cellulose fiber. Use an electron microscope to confirm whether the obtained dried cellulose fiber is fibrous ( figure 2 ). When it is determined that the fiber shape after drying is fibrous, the average fiber diameter is measured. The results are shown in Table 2.

manufacture example 3

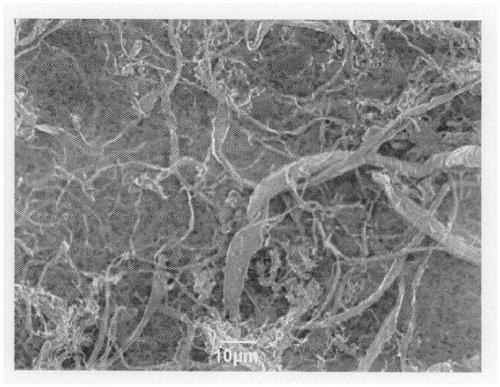

[0132] Condensed ricinoleic acid ester (trade name: CRS-75, manufacturer: Sakamoto Pharmaceutical Industry) was added as a surfactant to the manufacturing example in a manner of 1 part by mass relative to 100 parts by mass of cellulose fibers (solid content) 1 In the same 10% by mass aqueous dispersion of cellulose fibers obtained in the same manner, fully agitated and mixed. After that, it was heated and dried in the same manner as in Production Example 1 to obtain a granular dried body. Furthermore, as in Production Example 1, a pin mill was used for pulverization to obtain a dried cellulose fiber. Confirm with an electron microscope whether the obtained dried cellulose fiber is fibrous ( image 3 ). The fiber shape after drying is determined, and when it is a fiber shape, the average fiber diameter is measured. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com