A kind of preparation method of graphene reinforced FCC class high entropy alloy

A high-entropy alloy and graphene technology, which is applied in the field of graphene-enhanced FCC high-entropy alloy preparation, can solve problems such as uneven dispersion, undeveloped graphene, and reduced material performance, so as to ensure structural integrity and facilitate industrialization The effect of production and improvement of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

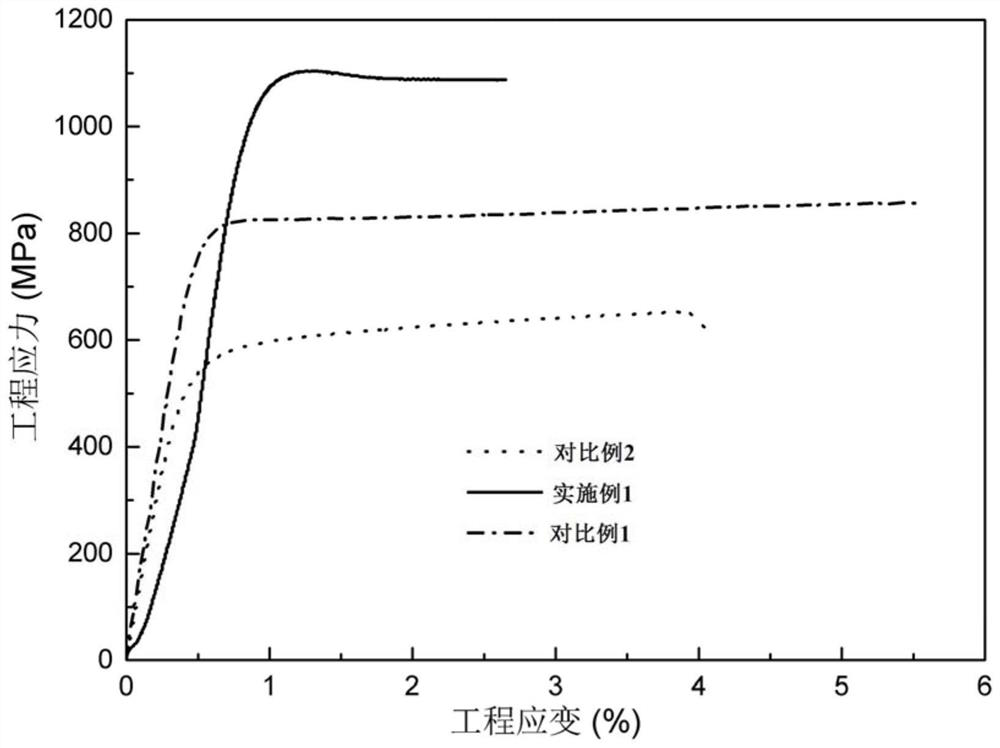

Examples

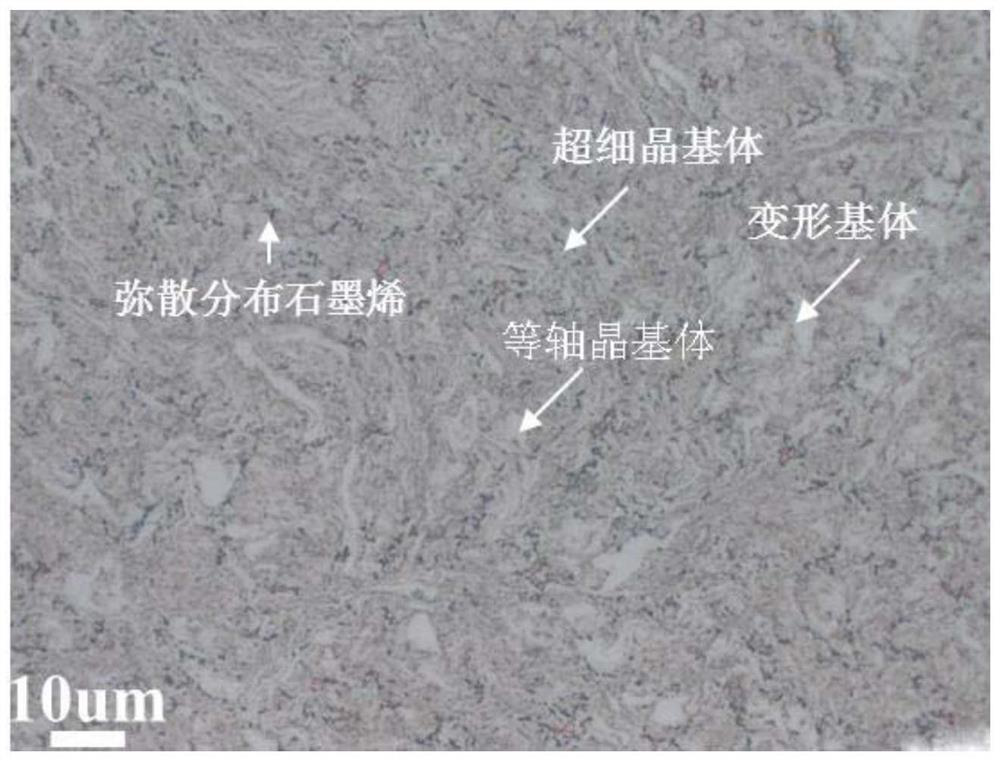

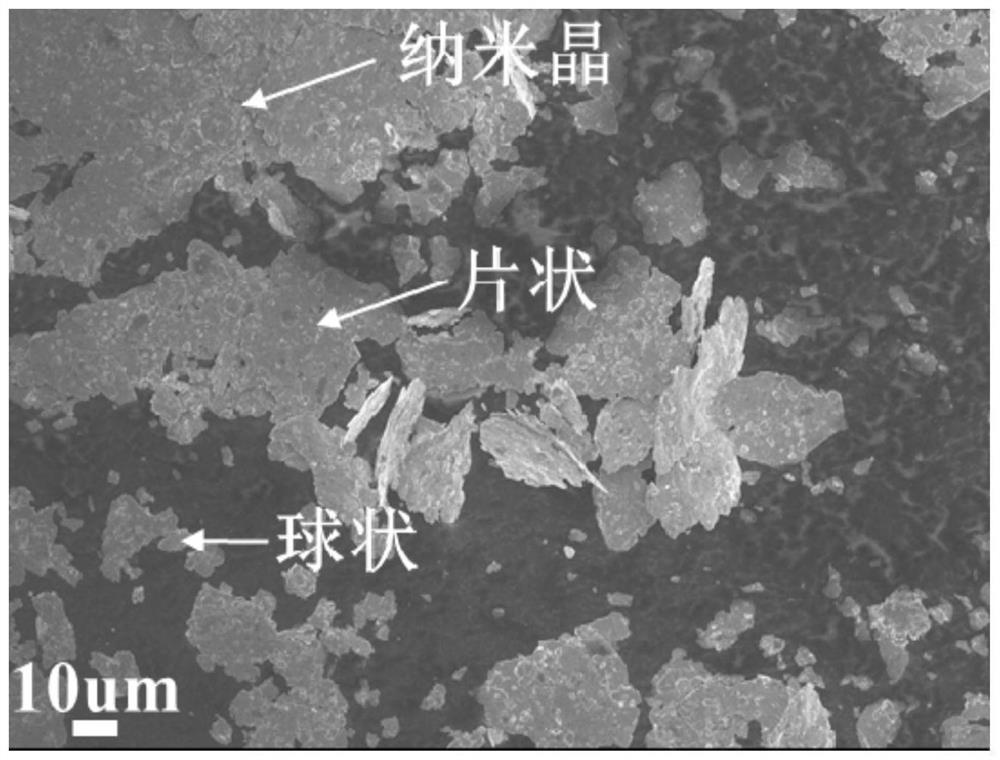

Embodiment 1

[0029] This embodiment includes the following steps:

[0030] Step 1. Raw material powder preparation: CoCrFeNiCu high-entropy alloy powder is prepared by gas atomization;

[0031] Step 2, short-time high-energy ball milling: 299.1 g of the CoCrFeNiCu high-entropy alloy powder with a particle size of 225 meshes prepared in step 1 was added to a planetary ball mill for ball milling, and then placed in a vacuum drying oven for drying; the ball milling process was carried out using The ball milling tank and balls are made of stainless steel, the diameters of the balls are 8mm, 5mm and 2mm and the mass ratio of the three kinds of balls is 3:2:1, the ratio of ball to material is 50:1, and the speed of ball milling is 450r / min, the time is 25min, and the process of stopping for 10min every 5min is alternately carried out, and 80mL ethanol is added as a process control agent during the ball milling process; the drying temperature is 80°C, the time is 15h, and the vacuum degree is -1...

Embodiment 2

[0047] This embodiment includes the following steps:

[0048] Step 1. Raw material powder preparation: CoCrFeNiCu high-entropy alloy powder is prepared by gas atomization;

[0049] Step 2, short-term high-energy ball milling: 49.95 g of the CoCrFeNiCu high-entropy alloy powder with a particle size of 120 meshes prepared in step 1 was added to a planetary ball mill for ball milling, and then placed in a vacuum drying oven for drying; the ball milling process was carried out using The ball milling tank and balls are made of stainless steel, the diameters of the balls are 8mm, 5mm and 2mm and the mass ratio of the three kinds of balls is 3:2:1, the ratio of ball to material is 15:1, and the speed of ball milling is 300r / min, the time is 5min, and the process of stopping for 10min every 5min is alternately carried out. During the ball milling process, ethanol is added as a process control agent; the drying temperature is 60°C, the time is 10h, and the vacuum degree is -1×10 -1 M...

Embodiment 3

[0053] This embodiment includes the following steps:

[0054] Step 1. Raw material powder preparation: CoCrFeNiCu high-entropy alloy powder is prepared by gas atomization;

[0055] Step 2, short-term high-energy ball milling: 99g of CoCrFeNiCu high-entropy alloy powder with a particle size of 200 meshes prepared in step 1 was added to a planetary ball mill for ball milling, and then placed in a vacuum drying oven for drying; the ball milling process used Both the ball milling tank and the balls are made of stainless steel, the diameters of the balls are 8mm, 5mm and 2mm and the mass ratio of the three kinds of balls is 3:2:1, the ratio of ball to material is 20:1, and the speed of ball milling is 350r / min , the time is 10min, and the process of stopping 10min for every 5min of ball milling is alternately carried out, and ethanol is added as a process control agent during the ball milling process; the drying temperature is 80°C, the time is 12h, and the vacuum degree is -1×10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com