Super-hydrophobic metal/ceramic composite coating with antibacterial property and preparation method thereof

A ceramic composite, super-hydrophobic technology, applied in the field of medical materials, can solve the problems of surgical failure, titanium alloy does not have antibacterial ability, wound infection and other problems, and achieves the effect of mechanical performance guarantee, tight bonding and uniform transition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The specific operation steps are as follows:

[0040] The metal / ceramic dual-phase composite coating preparation process uses the dual-cathode plasma sputtering deposition method to form a metal / ceramic composite coating with a micro-nano composite structure on the surface of the Ti-6Al-4V alloy workpiece, wherein:

[0041] a. Double cathode plasma sputtering process parameters:

[0042]

[0043] b. Sputtering target: mixed Fe 2 O 3 -Al-Cr-Co-Ni-Cu target, composition ratio (mass fraction,%): 23.49% Fe 2 O 3 , 7.93% Al, 15.27% Cr, 17.33% Co, 17.33% Ni, 18.65% Cu;

[0044] c. The type of workpiece material: Ti-6Al-4V alloy.

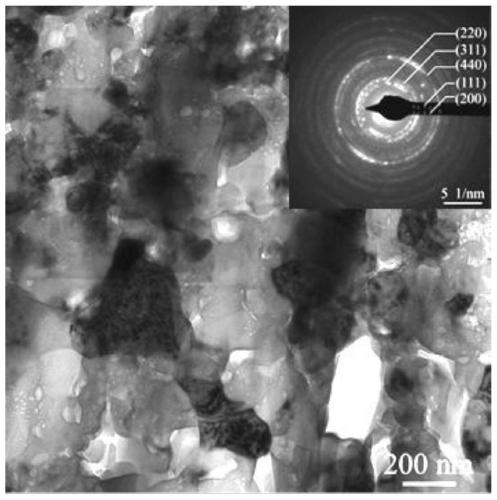

[0045] figure 1 It is a bright-field TEM image and a selected area diffraction ring of a metal / ceramic dual-phase composite coating. The transmission electron microscope observation shows that the coating is composed of a metal phase with a grain size of 100-500nm and a spinel ceramic phase, and the two phases are closely combined and the ...

Embodiment 2

[0052] The specific operation steps are as follows:

[0053] The metal / ceramic dual-phase composite coating preparation process uses the dual-cathode plasma sputtering deposition method to form a metal / ceramic composite coating with a micro-nano composite structure on the surface of the Ti-6Al-4V alloy workpiece, wherein:

[0054] a. Double cathode plasma sputtering process parameters:

[0055]

[0056] b. Sputtering target: mixed Fe 2 o 3 -Al-Cr-Co-Ni-Cu target, composition ratio (mass fraction,%): 23.49% Fe 2 o 3 , 7.93% Al, 15.27% Cr, 17.33% Co, 17.33% Ni, 18.65% Cu; c. The type of workpiece material: Ti-6Al-4V alloy. The comprehensive performance of the obtained coating is slightly lower than that of Example 1.

Embodiment 3

[0058] The specific operation steps are as follows:

[0059] The metal / ceramic dual-phase composite coating preparation process uses the dual-cathode plasma sputtering deposition method to form a metal / ceramic composite coating with a micro-nano composite structure on the surface of the Ti-6Al-4V alloy workpiece, wherein:

[0060] a. Double cathode plasma sputtering process parameters:

[0061]

[0062] b. Sputtering target: mixed Fe 2 o 3 -Al-Cr-Co-Ni-Cu target, composition ratio (mass fraction,%): 23.49% Fe 2 o 3 , 7.93% Al, 15.27% Cr, 17.33% Co, 17.33% Ni, 18.65% Cu; c. The type of workpiece material: Ti-6Al-4V alloy. The comprehensive performance of the obtained coating is slightly lower than that of Example 1.

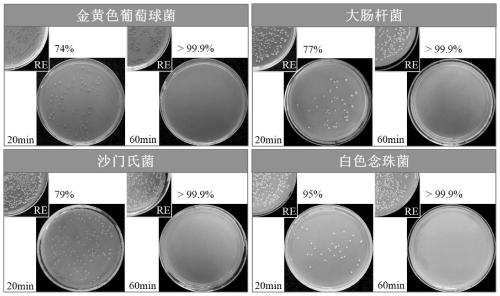

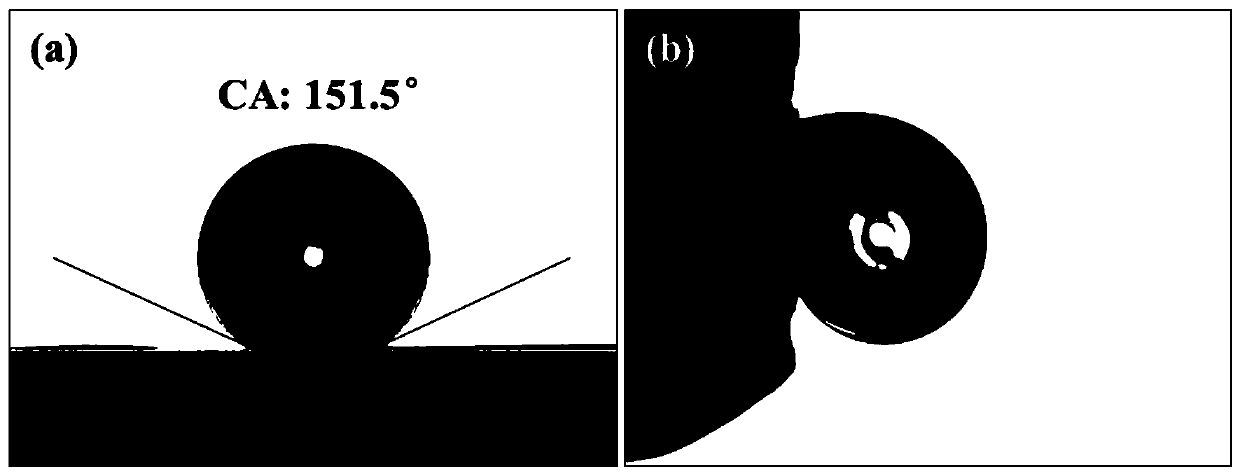

[0063] The invention adopts double-cathode plasma sputtering deposition technology as a means to prepare superhydrophobic metal / ceramic dual-phase composite coating with antibacterial performance on the surface of medical titanium alloy material. The coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com