Electromagnetic shielding and hydrophobic functional fabric with high absorption characteristics and preparation method thereof

A technology of electromagnetic shielding and functional fabrics, applied in textiles and papermaking, etc., can solve problems affecting the functional softness of fabrics, achieve good commercial application prospects, improve hydrophobic performance, and increase surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

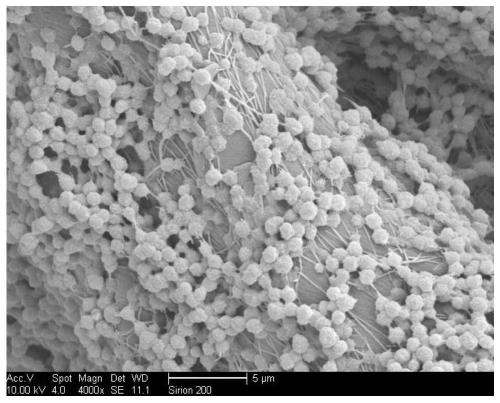

Image

Examples

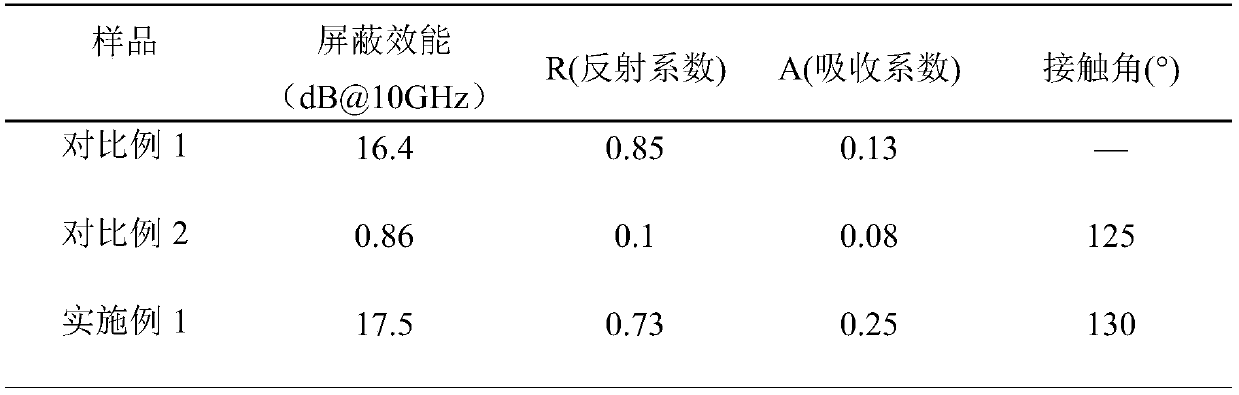

Embodiment 1

[0045] The concrete steps of preparation are:

[0046] Step 1: Add 0.1g of multi-walled carbon nanotubes and 0.6g of fluorescent whitening agent VBL into 30ml of deionized water, stir and mix thoroughly at room temperature, and ultrasonically disperse for 3 hours to obtain a uniform dispersion of multi-walled carbon nanotubes; take a piece Cotton fiber fabric with a thickness of 2mm, which is fully soaked in the obtained carbon nanotube dispersion, taken out, placed in an oven at 80°C for 60 minutes, and repeated this soaking-drying operation twice to obtain a conductive shielding cotton fabric;

[0047] Step 2: Dissolve 3g of polyvinylidene fluoride (PVDF) in 60ml of dimethylformamide (DMF), stir at 80°C for 8 hours, prepare a uniform solution, and apply it to the conductive shielding cotton obtained in step 1 On the fabric, and then placed in a constant temperature and humidity box with a temperature of 20°C and a humidity of 98% for 12 hours;

[0048] Step 3: Soak the cotton...

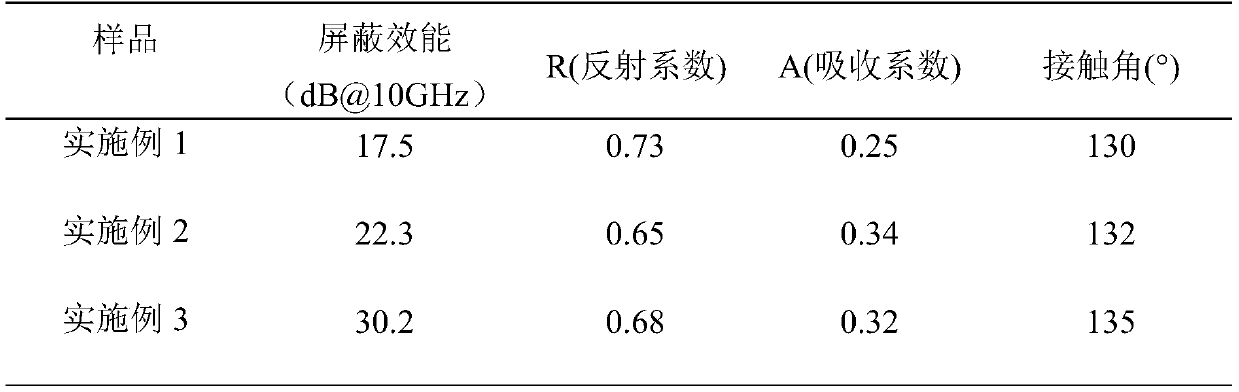

Embodiment 2

[0055] Step 1: Add 0.1g of multi-walled carbon nanotubes and 0.6g of fluorescent whitening agent VBL into 30ml of deionized water, stir and mix thoroughly at room temperature, and ultrasonically disperse for 3 hours to obtain a uniform dispersion of multi-walled carbon nanotubes; take a piece Cotton fiber fabric with a thickness of 2mm, which is fully soaked in the obtained carbon nanotube dispersion, taken out, placed in an oven at 80°C for 60 minutes, and repeated this soaking-drying operation twice;

[0056] Step 2: Dissolve 3g of polyvinylidene fluoride (PVDF) in 60ml of dimethylformamide (DMF), stir at 80°C for 8h, and after preparing a uniform solution, add 0.5g of ferric iron tetroxide (Fe 3 o 4 ) nanoparticles, fully stirred, ultrasonic 5h, prepared PVDF / Fe 3 o 4 the dispersion liquid;

[0057] Step 3: PVDF / Fe obtained in Step 2 3 o 4 The dispersion liquid is coated on the conductive cotton fabric obtained in step 1, and then placed in a constant temperature and h...

Embodiment 3

[0060] Step 1: Add 0.1g of multi-walled carbon nanotubes and 0.6g of fluorescent whitening agent VBL into 30ml of deionized water, fully stir and mix at room temperature, and ultrasonically disperse for 3 hours to obtain a uniform multi-walled carbon nanotube dispersion; take a piece Cotton fiber fabric with a thickness of 2mm, which is fully soaked in the obtained carbon nanotube dispersion, taken out, placed in an oven at 80°C for 60 minutes, and repeated this soaking-drying operation 3 times;

[0061] Step 2: Dissolve 3g of polyvinylidene fluoride (PVDF) in 60ml of dimethylformamide (DMF), stir at 80°C for 8h, and after preparing a uniform solution, add 1g of ferric oxide (Fe 3 o 4 ) nanoparticles, fully stirred, ultrasonic 5h, prepared PVDF / Fe 3 o 4 the dispersion liquid;

[0062] Step 3: PVDF / Fe obtained in Step 2 3 o 4 The dispersion liquid is coated on the conductive cotton fabric obtained in step 1, and then placed in a constant temperature and humidity box with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com