Optical lens wavefront measurement method using phase measurement deflection technology

An optical lens and phase measurement technology, applied in the field of optical imaging, can solve the problems of low resolution and high cost, achieve high sensitivity, low cost, and improve the signal-to-noise ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

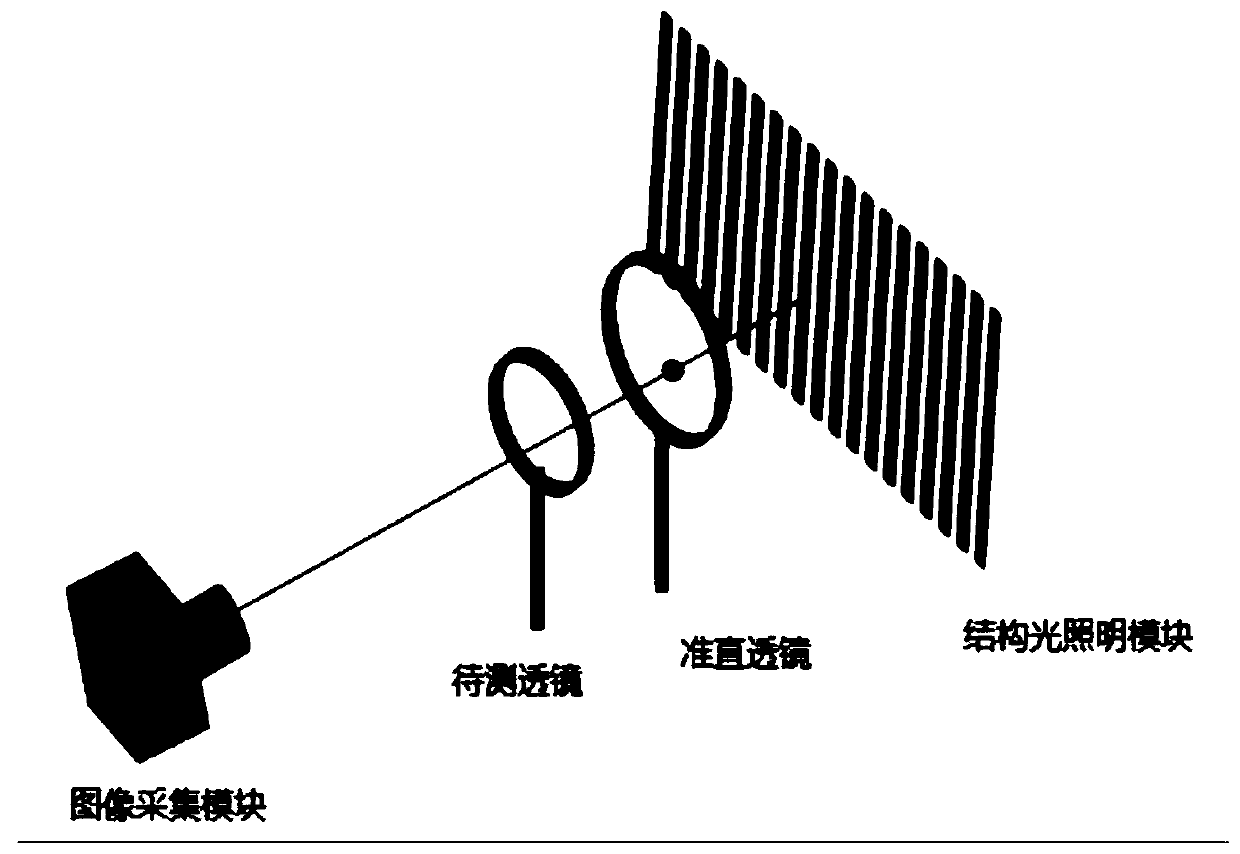

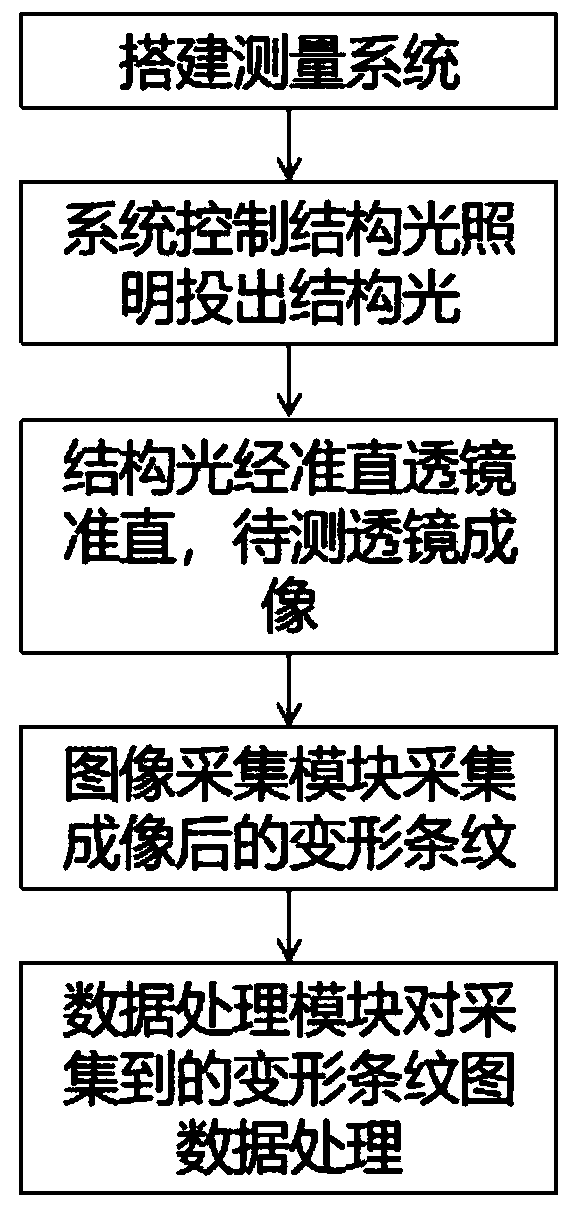

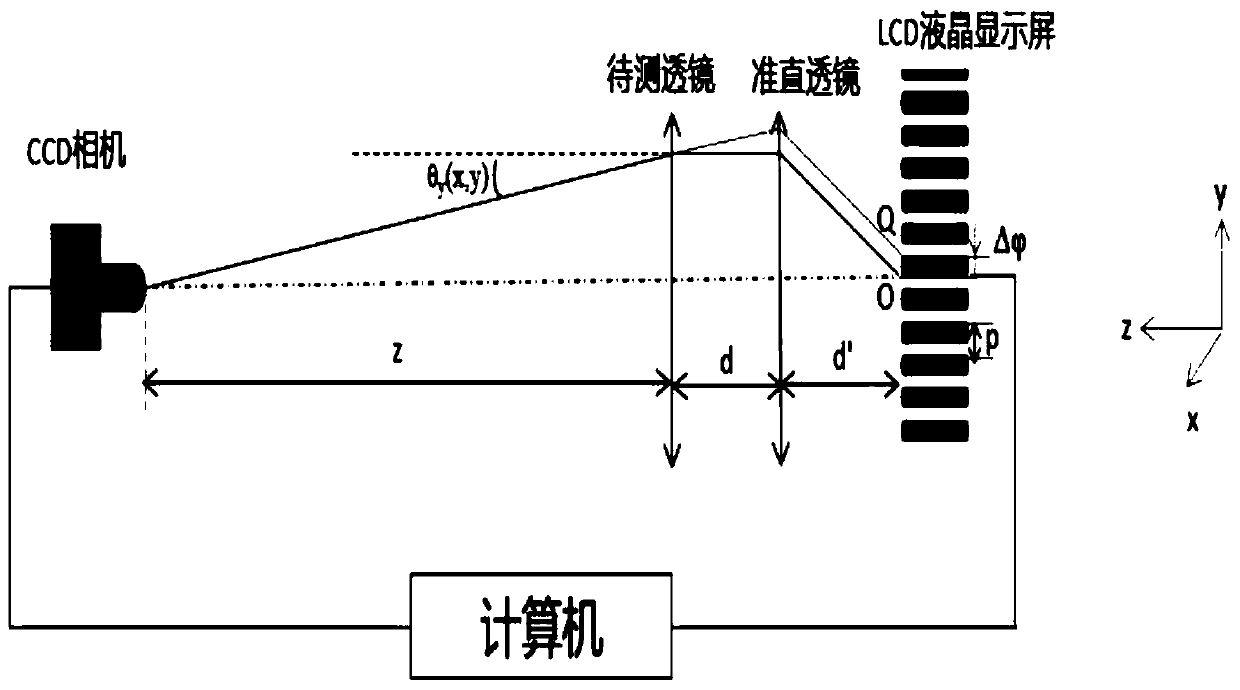

[0035] Such as Figure 1-2 As shown, the present invention provides a method for measuring the wavefront of an optical lens using phase measurement deflection, which includes the following steps:

[0036] Step 1. Use a computer to generate a phase-shifted sinusoidal fringe structured light as a light source. The structured light is collimated and projected onto the surface of the lens to be tested, and imaged by it. The lens to be tested can be a single lens or a combination. For lenses or other phase objects, structured light passes through the lens to be tested, refracts inside it, and exits at a certain deflection angle, thereby forming deformed fringe structured light;

[0037] Step 2: The image acquisition module collects the deformed fringe structured light;

[0038] Step 3. Use the phase shift recovery algorithm to extract the wrapped phase in the structured light by using the collected light intensity of the deformed fringe structured light; use the phase unwrapping algorith...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com