Electrode for biosensor for NADH measurement and manufacturing method therefor

A biosensor and electrode manufacturing technology, applied in biochemical equipment and methods, measurement devices, and microbial determination/inspection, etc., can solve the problems of complex pretreatment process, reduced selectivity, damaged electrode surface, etc., and achieve the maintenance of sensitivity. and selectivity, improved surface modification efficiency, and stable current flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

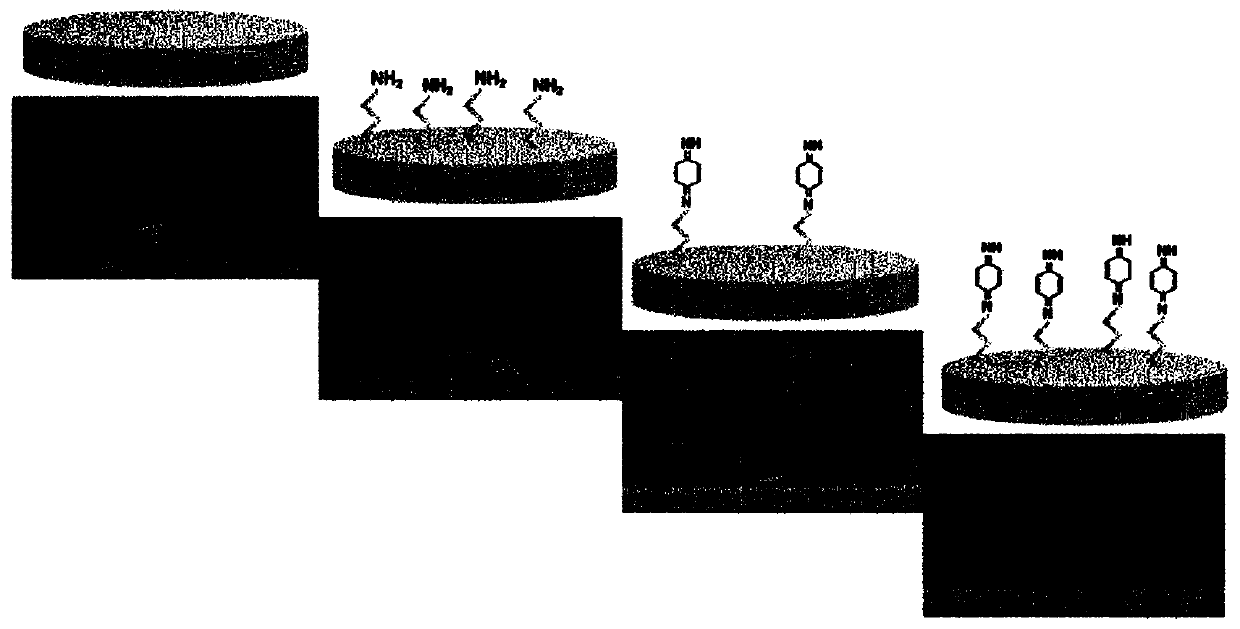

[0055] [Manufacturing example] Manufacture of a biosensor electrode for NADH measurement

[0056] An electrode suitable for a biosensor for NADH measurement was fabricated by performing the following steps.

[0057] With 10mM sulfuric acid (H 2 SO 4 ) to wash the gold (Au) electrode. Then, in order to form a self-assembled film, the electrode was immersed in 4-aminothiophenol prepared at a molar concentration of 10 mM, followed by incubation for 2 hours. Thereafter, the electrode is immersed in a phosphate buffer solution with a molar concentration of 100 mM (high concentration), and a voltage sweep is performed from 0.8 V to -0.4 V potential by cyclic voltammetry to form N-phenylquinone di imine (hereinafter referred to as "NPQD"). After immersing the electrode formed with the NPQD into a phosphate buffer with a molar concentration of 10 mM (low concentration), apply the same voltage as in the step of forming the NPQD in the 100 mM phosphate buffer to perform voltage sc...

Embodiment 1

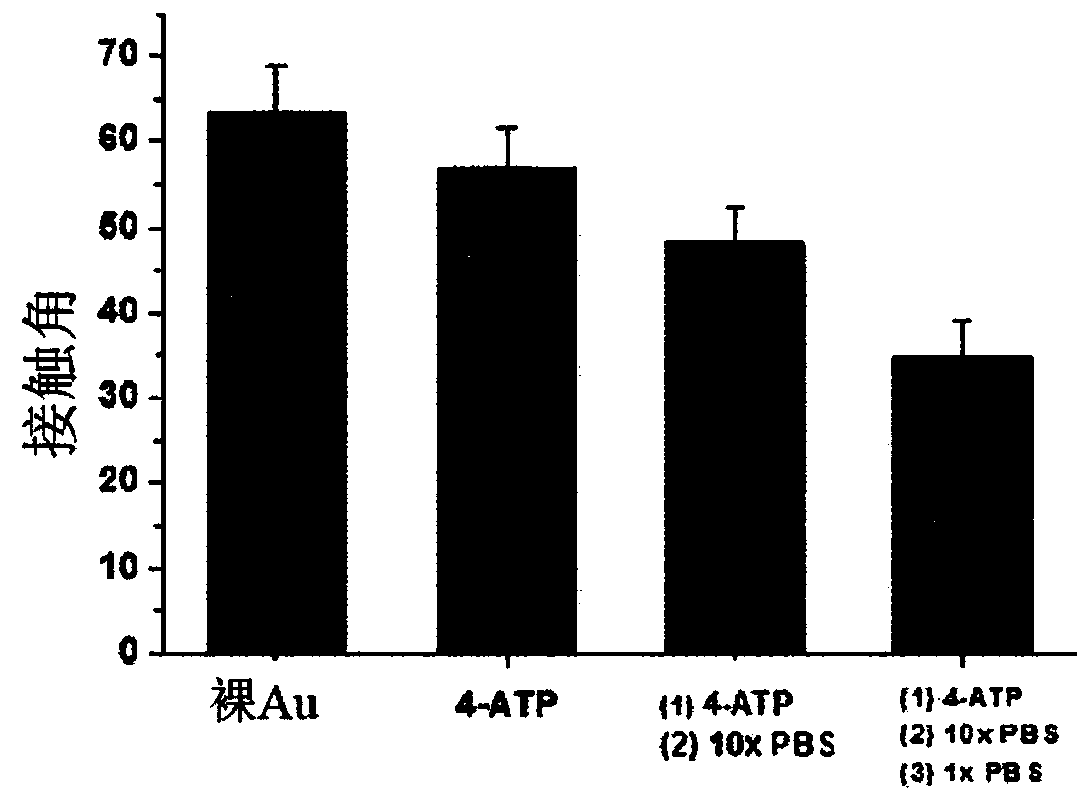

[0060] [Example 1] 4-aminothiophenol contact angle measurement

[0061] Changes in the contact angles of the NPQDs formed on the surfaces of the electrodes according to the manufacturing examples were confirmed. Specifically, after 10 μl of distilled water was dropped on the electrode of the preparation example at room temperature and a humidity of 46%, each electrode was photographed and analyzed by using the method provided by the manufacturer through the IMAGE J software to measure and analyze the contact angle, which result in figure 1 with figure 2 shown in .

[0062] Such as figure 1 with figure 2 As shown, it can be seen that the NPQDs bound to the surface of the preparation example can be bound to the surface in a larger amount, whereby the surface of the electrode is converted to have greater hydrophilicity. In particular, as figure 2 As shown, there was little change in the contact angle between the comparative example and the case where only 4-aminothio...

Embodiment 2

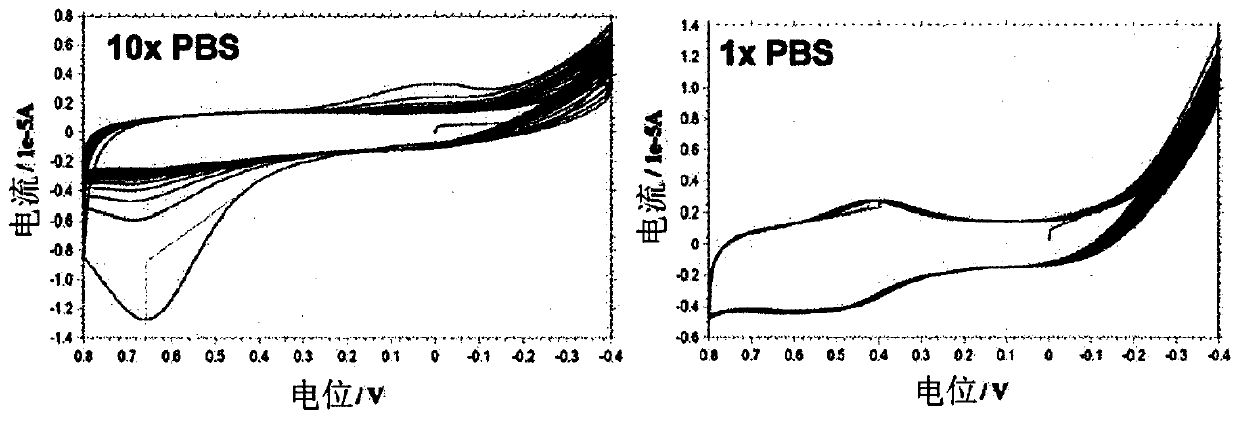

[0064] [Example 2] Measuring comparative current value stability

[0065] In order to compare the stability of the current value of high-concentration phosphate buffer (100mM) and low-concentration phosphate buffer (10mM), the CH1040C series multipotentiometer device was used to perform electrochemical analysis using the protocol provided by the manufacturer. The result is as image 3 shown.

[0066] Such as image 3 As shown, the current value measured in the high-concentration phosphate buffer solution is relatively unstable, but the current value is very stable in the low-concentration phosphate buffer solution of 10 mM.

[0067] From the above results, it can be seen that in the production according to the production example of the present invention, the current value can be stabilized by performing the polymerization reaction by changing the steps under the conditions of high concentration and low concentration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com