Low-density heat-conducting gel and preparation method thereof

A low-density, gel technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of increasing the weight of parts, high density of thermally conductive powders, and increased material costs, and achieve improved thermal conductivity and thermal conductivity. Good, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

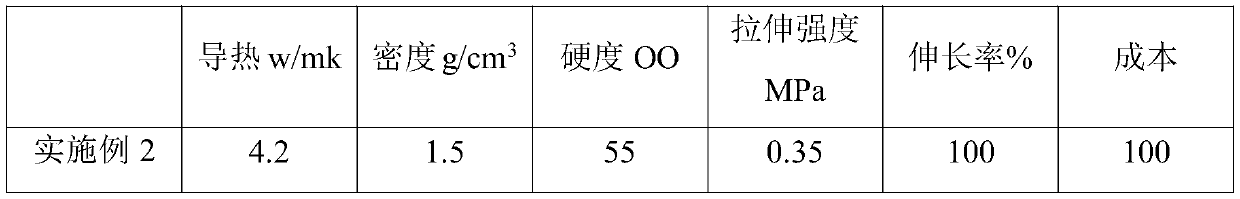

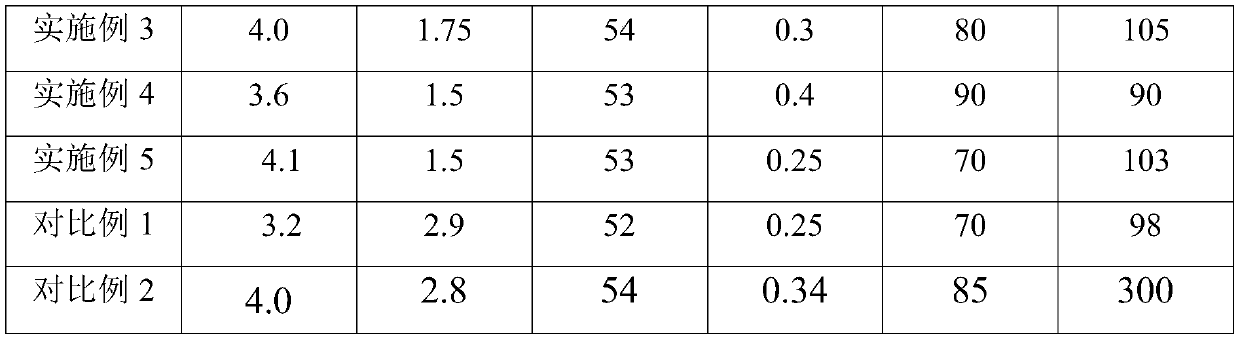

Examples

preparation example Construction

[0072] On the other hand, the present invention also provides a method for preparing a low-density thermally conductive gel, comprising the following steps:

[0073] Step S1, weighing the materials of component A and component B for preparing the low-density thermally conductive gel according to the mass ratio;

[0074] Step S2, add the weighed materials of each component into the double planetary mixer, mix evenly and draw a vacuum, and vacuum defoam to obtain the A component mixture and the B component mixture; put the A component mixture into the double group In the tube A, put the B component mixture into the two component tube B; the vacuum defoaming is to remove the gas brought in during the stirring, otherwise the air inside will not be discharged during curing, resulting in pores in the colloid, affecting performance;

[0075] Step S3, mixing the prepared A-component mixture and B-component mixture, and curing at room temperature for 22-25 hours.

[0076] Specificall...

Embodiment 1

[0083] This embodiment provides a kind of surface silver-plated hollow microspheres (hereinafter referred to as silver-plated hollow microspheres), and the silver-plated hollow microspheres are prepared by the following preparation method:

[0084] S1, pretreatment of hollow microbeads;

[0085] Specifically, the pretreatment of hollow microbeads in S1 includes the following steps:

[0086] S101, coarsening: add 2g / L sodium fluoride solution to 15mL / L hydrofluoric acid to form a roughening solution, stir evenly; add 10g hollow microbeads to 300mL roughening solution, and sonicate in an ultrasonic generator for 20min at room temperature , stand still; after the powder settles, remove the roughening liquid, and wash the powder with water for 3 times;

[0087] S102. Sensitization: Pour the sensitizing solution into the washed powder at room temperature, ultrasonicate in an ultrasonic generator for 20-30 minutes, and let stand; after the powder settles, remove the sensitizing sol...

Embodiment 2

[0091] This embodiment provides a low-density thermally conductive gel, and the low-density thermally conductive gel is prepared by the following method:

[0092] A component:

[0093] 1) Weigh 40g of vinyl-terminated silicone oil with a viscosity of 500mPa·s, 60g of vinyl-terminated silicone oil with a viscosity of 3000mPa·s, 6.5g of dimethyl silicone oil with a viscosity of 100mPa·s, and 300g of silver-coated hollow microspheres with a particle size of 20μm , 600 g of spherical alumina with a particle size of 25 μm, and 0.2 g of chloroplatinic acid-isopropanol complex with a platinum content of 500 ppm;

[0094] 2) Put the above-mentioned weighed materials into the planetary mixer (add silicone oil first, then add filler); adjust the revolution speed to 50rpm, the dispersion speed to 500rpm, mix for 60min, and then vacuum defoam for 60min;

[0095] 3) Put the above mixed materials into the two-component tube A tube.

[0096] B component:

[0097] 1) Weigh 40g of vinyl-ter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com