High-wear-resistance low-migration environment-friendly ink and preparation method thereof

A low-migration, high-wear-resistance technology, used in inks, household appliances, applications, etc., to achieve good wear-resistance and curing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

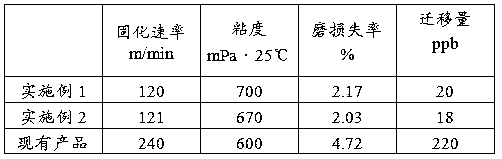

Examples

Embodiment 1

[0023] The present invention discloses a high wear-resistant and low-migration environmentally friendly ink, which comprises the following components in terms of 100kg:

[0024] Connecting material 50kg, described connecting material comprises that mass ratio is 3:5:0.5 fumaric acid rosin modified acrylic resin, rosin epoxy acrylate and acrylic acid monomer;

[0025] Wear-resistant filler 5kg, described wear-resistant filler comprises that mass ratio is 1:3 nanometer silicon dioxide and nano-alumina; During the process, the silicon oxide particles and the ink particles cannot be completely dissolved and bonded, but many tiny cracks are generated at the junction of the ink and the nano-silica, and the connection force between the nano-alumina and the ink is smaller than that of the nano-silicon oxide, and the friction and wear machine The substances worn by the grinding wheel are mainly water-based ink and nano-alumina particles. At this time, nano-alumina mainly plays the role...

Embodiment 2

[0038] The present invention discloses a high wear-resistant and low-migration environmentally friendly ink, which comprises the following components in terms of 100kg:

[0039] Connecting material 55kg, described connecting material comprises the fumaric acid rosin modified acrylic resin, rosin epoxy acrylate and acrylic acid monomer that mass ratio is 5:5:1;

[0040] Wear-resistant filler 10kg, described wear-resistant filler comprises the nano-silicon dioxide and nano-alumina that mass ratio is 1:5; Because nano-silicon oxide and nano-alumina are the wear-resistant material that is insoluble in water-based ink, water-based ink is dry During the process, the silicon oxide particles and the ink particles cannot be completely dissolved and bonded, but many tiny cracks are generated at the junction of the ink and the nano-silica, and the connection force between the nano-alumina and the ink is smaller than that of the nano-silicon oxide, and the friction and wear machine The su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com