Ultrahigh magnetic energy product neodymium iron boron permanent magnet material and preparation method thereof

A permanent magnet material, NdFeB technology, applied in magnetic materials, inductance/transformer/magnet manufacturing, magnetic objects, etc., can solve the problems of increased brittleness of permanent magnets, low processing yield, new equipment investment, etc., to improve Processability, Coercivity Improvement, Rare Earth Phase Increase Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

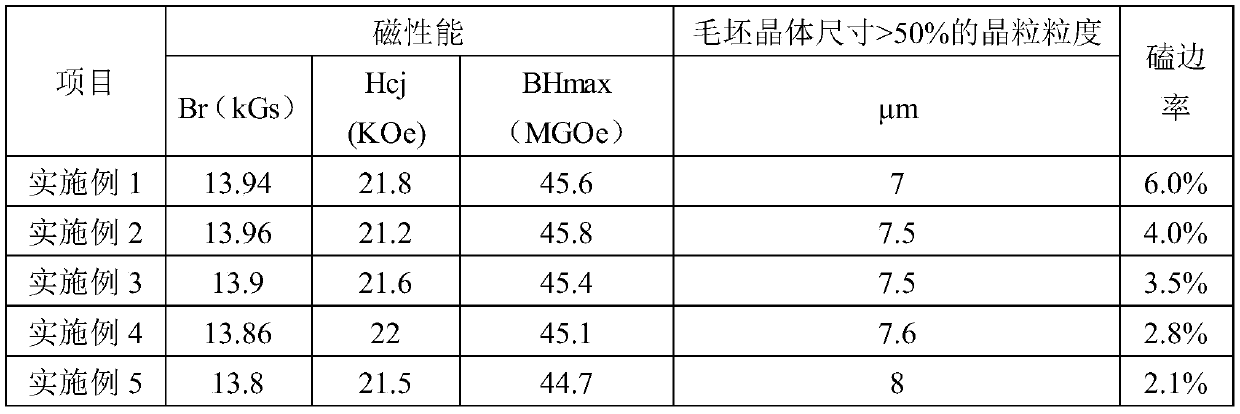

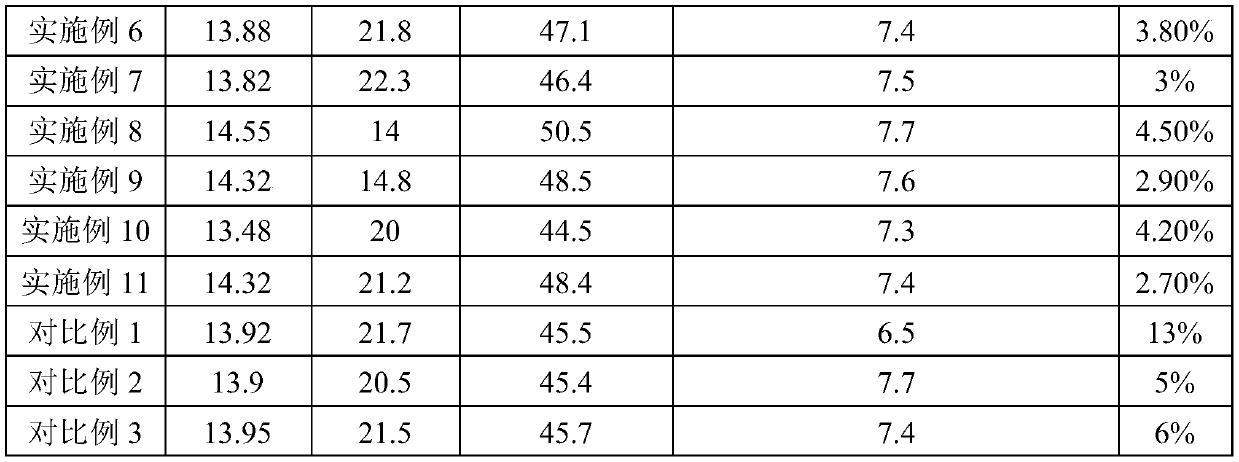

Embodiment 1

[0051] The raw materials are smelted according to the nominal composition of Pr7.1 Nd21.3 Tb1.76 B0.9 Cu0.12 Co1.38 Zr0.2 Ga0.24Fe67, and made into flakes of 0.2mm to 0.4mm, and the flakes are hydrogen broken. The hydrogen content of the coarse powder after hydrogen crushing is 1000-1200ppm. The obtained hydrogen crushed powder is subjected to jet milling and the X50 is controlled at 4.5μm-4.7μm, and the oxygen content in the grinding chamber is controlled at 25ppm-40ppm. The powder is pressed under the action of a 1.6T magnetic field. The pressed molded blank is subjected to isostatic pressing treatment, then sintered, and degassed at 880°C for 5 hours to keep the vacuum degree less than 20Pa, then the temperature is raised, and sintered at 1095°C / 5h, and the first step of aging treatment is carried out at 900°C And 490 ℃ the second step of aging treatment, and test the magnetic properties and microstructure to observe and test the grain size.

Embodiment 2

[0053] The jet mill grinding particle size X50 in Example 1 is controlled at 4.9 μm-5.1 μm, and the parameters of other steps are the same.

Embodiment 3

[0055] Add 0.3wt% of small pieces of PrNd alloy to the flakes in Example 1, and control the grinding particle size X50 of the jet mill at 4.9 μm to 5.1 μm, and the parameters of other steps are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com