Solid beverage rich in dietary fibers and plant-based sugar substitutes and preparation method of solid beverage

A dietary fiber and solid beverage technology, applied in the field of food processing, can solve the problems of thin, unappeared, and insufficient intake of dietary fiber, and achieve the effects of controlling blood sugar, regulating intestinal flora, and reducing intestinal gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

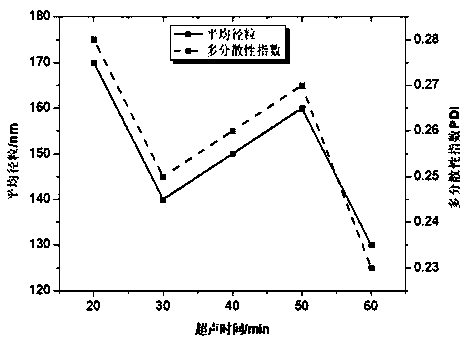

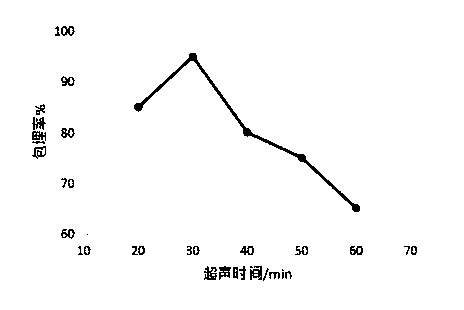

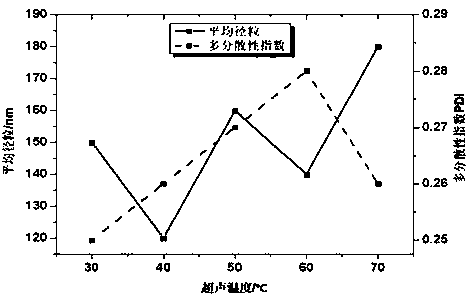

[0036] (1) Weigh raw materials by weight: 65 parts of resistant dextrin, 50 parts of erythritol, 10 parts of L-arabinose, 3 parts of steviol glycoside, dissolve in water, and the mass ratio of water to raw materials is 4-5: 1. The temperature of the water is 40°C. After mixing evenly, carry out ultrasonic embedding treatment in a water bath. The ultrasonic temperature is 50°C, the ultrasonic time is 30 min, and the ultrasonic power is 500 W, so as to obtain a mixed system for embedding nanoparticles.

[0037] (2) Carry out spray drying, the air inlet temperature is 170°C, the outlet temperature is 80°C, and the time is 20 s, and then ultrafine pulverization, the pulverization fineness is 80-200 mesh, and the solid beverage product is obtained.

[0038] In order to ensure a good eating taste and body feeling, the present invention recommends taking 5-10 g per day, preferably after a dilution factor of 1:50-80.

Embodiment 2

[0040] (1) Weigh raw materials by weight: 50 parts of resistant dextrin, 45 parts of erythritol, 5 parts of L-arabinose and 1 part of steviol glycoside are dissolved in water, and the mass ratio of water to raw materials is 4-5:1 , the temperature of the water is 40°C, after mixing evenly, carry out the water bath ultrasonic embedding treatment, the ultrasonic temperature is 70°C, the ultrasonic time is 60 min, the ultrasonic power is 200 W, and the nano-scale particle embedding mixed system is obtained;

[0041] (2) Carry out spray drying, the air inlet temperature is 130°C, the outlet temperature is 60°C, and the time is 30 s, and then ultrafine pulverization, the pulverization fineness is 80-200 mesh, and the solid beverage product is obtained.

Embodiment 3

[0043] (1) Weigh parts by mass of raw materials: 55 parts of resistant dextrin, 65 parts of erythritol, 15 parts of L-arabinose and 2 parts of steviol glycoside are dissolved in water, and the mass ratio of water to raw materials is 4-5:1 , the temperature of water is 40°C, after mixing evenly, carry out ultrasonic embedding treatment in a water bath, the ultrasonic temperature is 30°C, the ultrasonic time is 10 min, and the ultrasonic power is 800 W, to obtain a nano-scale particle embedding mixed system;

[0044] (2) Carry out spray drying, the air inlet temperature is 180°C, the outlet temperature is 90°C, and the time is 5 s, and then ultrafine pulverization, the pulverization fineness is 80-200 mesh, and the solid beverage product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com