Method for reducing exhaust emission of engine

An exhaust emission and engine technology, which is applied in separation methods, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., to achieve the effects of water resistance, sulfur resistance, long time and long activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

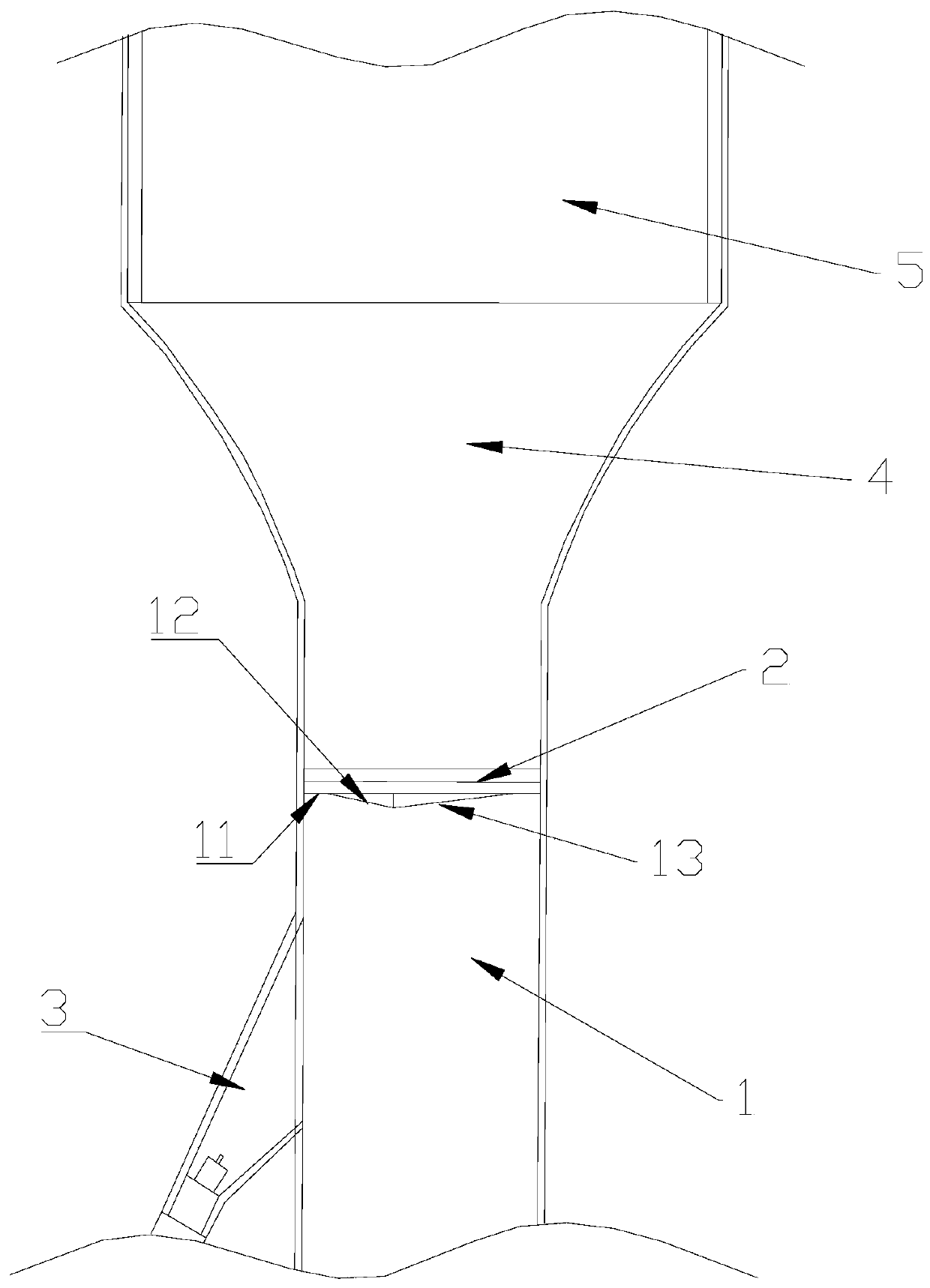

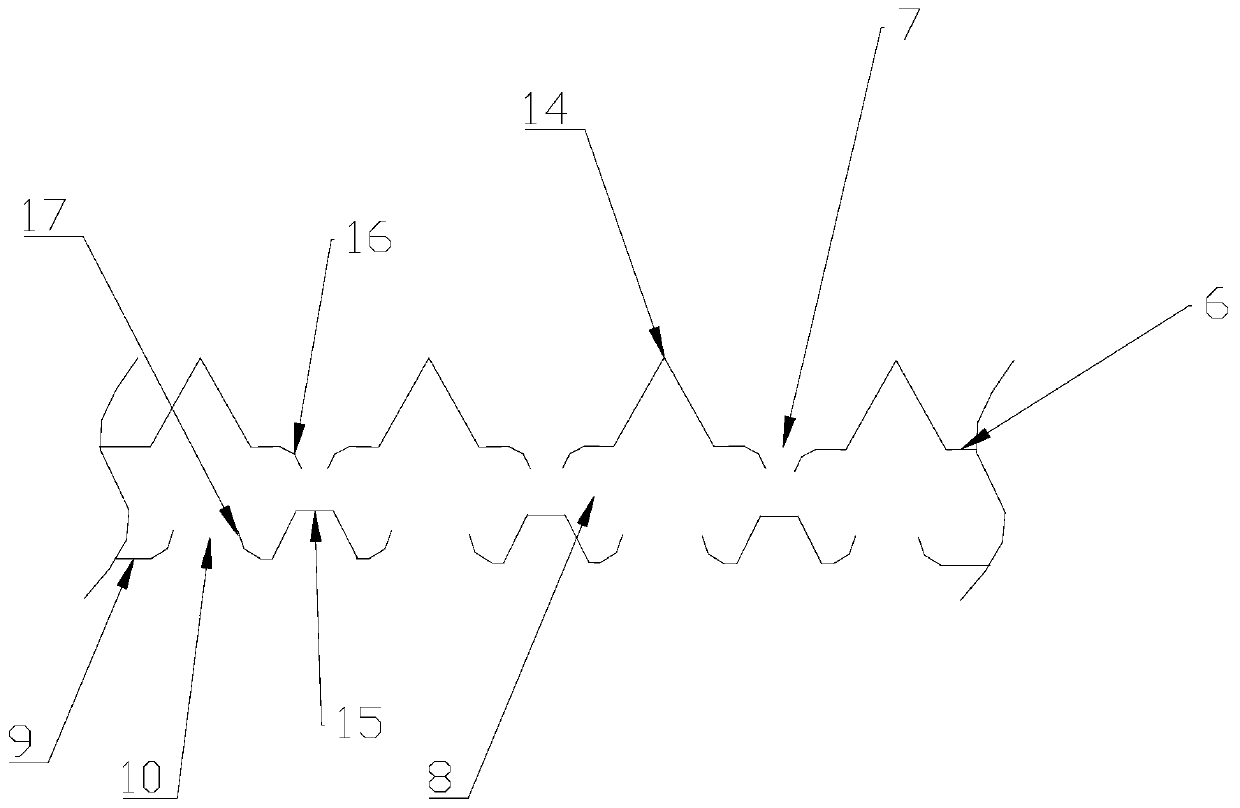

[0020] In order to clearly illustrate the technical features of the present solution, the present application will be described in detail below through specific implementation modes.

[0021] The synthesis method of each catalyst is as follows:

[0022] S1. Prepare solutions of titanium chloride, ammonium tungstate and ammonium metavanadate; prepare a mixture of kaolin, magnesium oxide, aluminum fluoride and cellulose acetate;

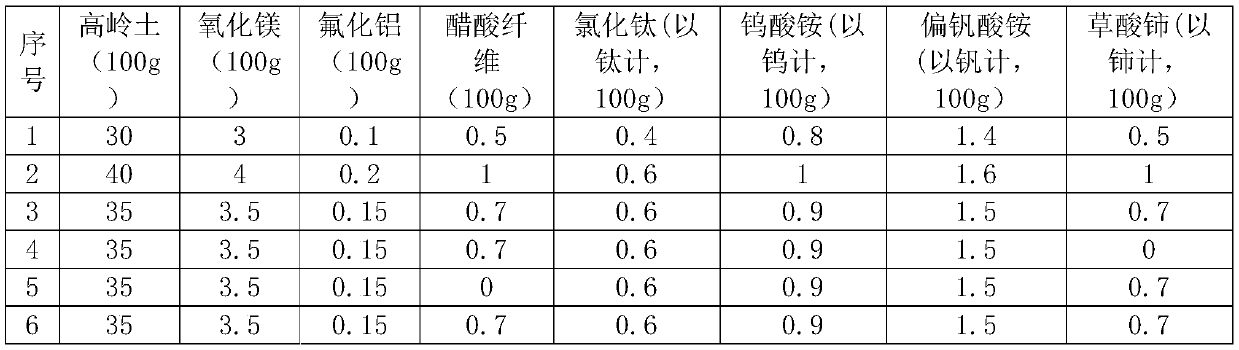

[0023] S2. Immediately after mixing titanium chloride, ammonium tungstate, and ammonium metavanadate, put the mixture of kaolin, magnesium oxide, aluminum fluoride, and cellulose acetate into ball milling treatment. The ball milling time is 60 minutes. The specific components are shown in Table 1;

[0024] Table 1:

[0025]

[0026] S3. Immediately freeze the slurry obtained in S2, and then freeze-dry;

[0027] S4. Oxidizing and roasting the freeze-dried material obtained in S3, that is, performing roasting operations under the action of flowing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com