Entire-water polyurethane rigid foam, and preparation method and application thereof

A rigid foam and polyurethane technology, applied in the field of rigid foam, can solve the problems of polyether polyol high hydroxyl value consumption of isocyanate, increased foam density, and poor fluidity of the system, achieving good dimensional stability and high foam density. Small, viscosity-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

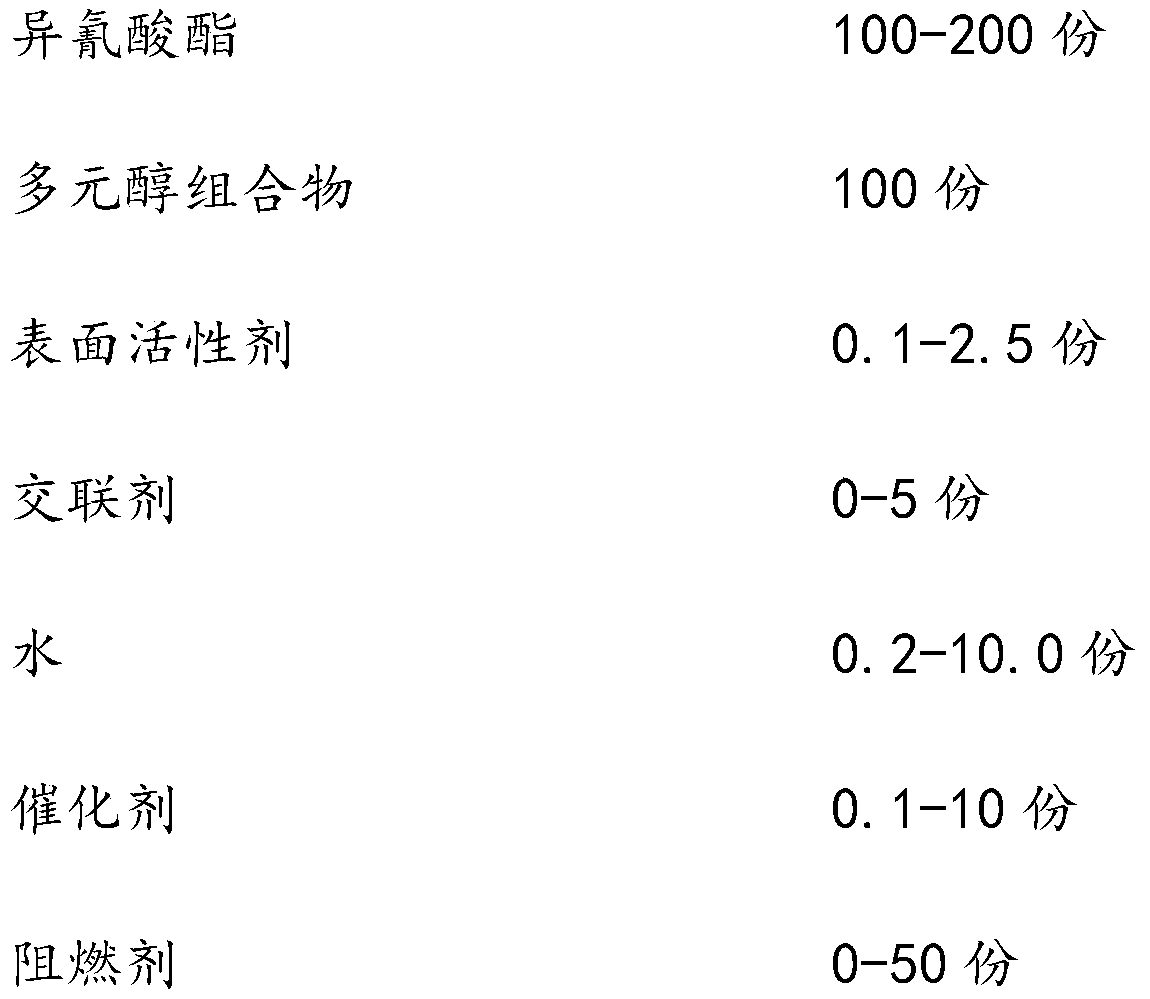

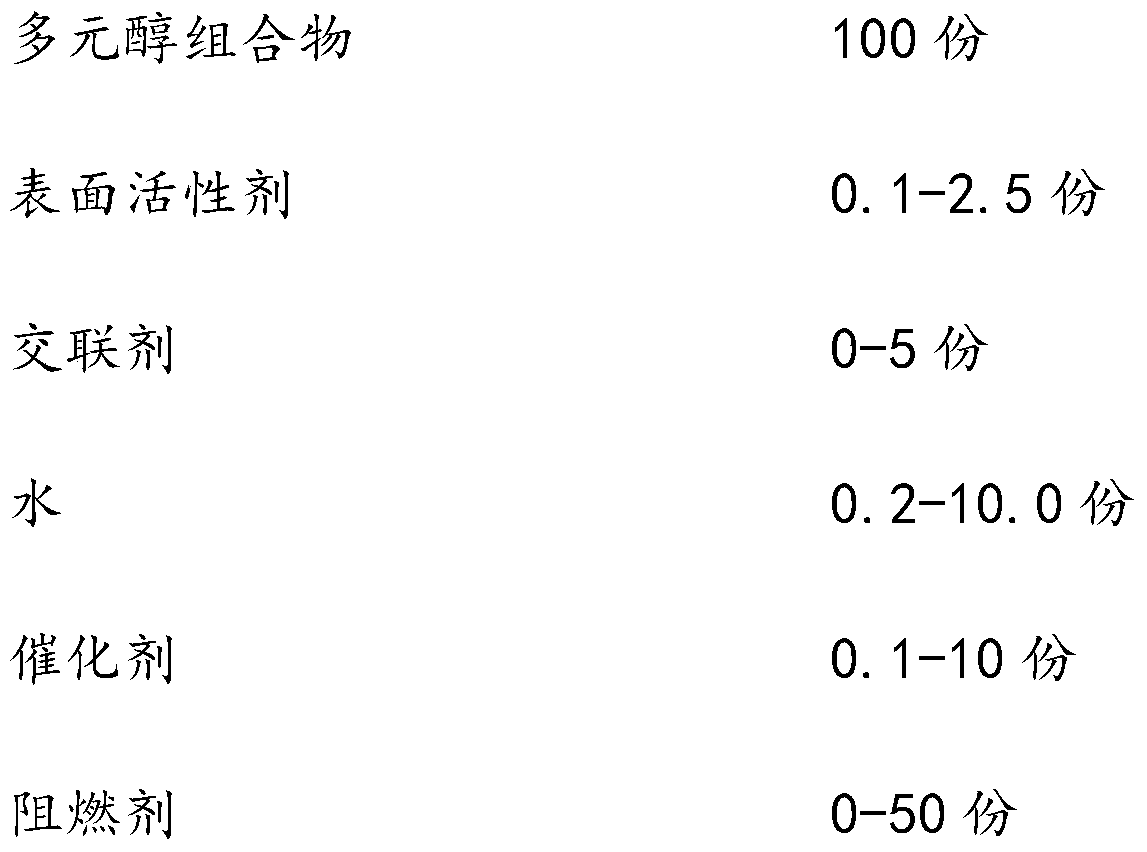

[0041] The present embodiment provides a kind of full water polyurethane rigid foam, and its raw material is as follows:

[0042] The first polyether polyol 350G: 100g, produced by Jiahua Chemical (Binzhou) Co., Ltd., functionality 4-5, number average molecular weight 600-800, hydroxyl value 330-370mgKOH / g, viscosity 700-1200mPa·s (25℃ ), the water content is less than 0.1%; the acid value is less than 0.1% mgKOH / g;

[0043]Catalyst: 0.2g of pentamethylenediethylenetriamine, 0.1g of 1,3,5-tris(dimethylaminopropyl)hexahydrotriazine, 1g of dimethylcyclohexylamine;

[0044] Silicone surfactant: Momentive L-6900 2g;

[0045] Water: 5g;

[0046] Crosslinking agent: glycerin 1.0g;

[0047] Flame retardant: 10g of tris (2-chloropropyl) phosphate;

[0048] Isocyanate: 176g PM200 (Wanhua Chemical Group Co., Ltd.).

[0049] The preparation method of above-mentioned poly all-water polyurethane rigid foam, comprises the steps:

[0050] (1) Accurately weigh the above-mentioned raw ma...

Embodiment 2

[0054] The present embodiment provides a kind of full water polyurethane rigid foam, and its raw material is as follows:

[0055] The first polyether polyol 3776: 100g, produced by Jiahua Chemical (Binzhou) Co., Ltd., functionality 4-5, number average molecular weight 600-800, hydroxyl value 310-350mgKOH / g, viscosity 1500m-3500Pa·s (25℃ ), the water content is less than 0.1%; the acid value is less than 0.1% mgKOH / g;

[0056] Catalyst: 2g of pentamethylenediethylenetriamine, 1g of 1,3,5-tris(dimethylaminopropyl)hexahydrotriazine, 1g of potassium acetate, 2g of triethylenediamine;

[0057] Silicone surfactant: Mester M-198 2g;

[0058] Water: 5g;

[0059] Crosslinking agent: triethanolamine 1.0g;

[0060] Flame retardant: tetrabromophthalic anhydride diol 50g;

[0061] Isocyanate: 180g PM400 (Wanhua Chemical Group Co., Ltd.).

[0062] The preparation method of above-mentioned poly all-water polyurethane rigid foam, comprises the steps:

[0063] (1) Accurately weigh the ab...

Embodiment 3

[0067] The present embodiment provides a kind of full water polyurethane rigid foam, and its raw material is as follows:

[0068] The first polyether polyol 7820: 100g, produced by Shanghai Fujia Fine Chemical Co., Ltd., functionality 6-8, number average molecular weight 800-1000, hydroxyl value 260-300mgKOH / g, viscosity 700-1500mPa·s (25℃) , the water content is less than 0.1%; the acid value is less than 0.1% mgKOH / g;

[0069] Catalyst: 0.1g of pentamethylenediethylenetriamine, 0.5g of 1,3,5-tris(dimethylaminopropyl)hexahydrotriazine, 0.2g of potassium acetate, 0.5g of triethylenediamine;

[0070] Silicone surfactant: Dongjun H360 2g;

[0071] Water: 5g;

[0072] Crosslinking agent: glycerin 1.0g;

[0073] Flame retardant: red phosphorus 30g;

[0074] Isocyanate: 173 g M20S (BASF AG).

[0075] The preparation method of above-mentioned poly all-water polyurethane rigid foam, comprises the steps:

[0076] (1) Accurately weigh the above-mentioned raw materials except the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com