Composite electrostatic spinning micro-nano fiber antibacterial non-woven sanitary material and preparation method thereof

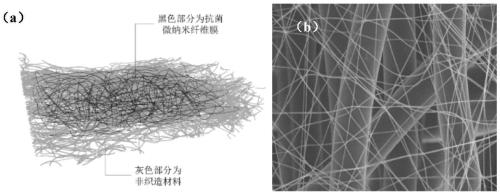

A technology of micro-nano fibers and non-woven materials, applied in the field of sanitary materials and their preparation, can solve the problems of reducing the air permeability and water permeability of sanitary materials, high cost, low safety, etc., and achieves safe antibacterial, small diameter, large size Effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Equipped with a spinning solution containing antibacterial agents: polyacrylonitrile (PAN, relative molecular mass 85000), Shanghai Macleans Biochemical Technology Co., Ltd.; N,N-dimethylformamide (DMF, analytical pure), Sinopharm Group Chemical Reagent Co., Ltd.; Didecyl Dimethyl Ammonium Chloride (DDAC, analytical grade), Shanghai Aladdin Biochemical Technology Co., Ltd.; add 65g of PAN solid powder to 500mL of DMF solution at 25°C Stir quickly until the spinning solution is clear and transparent, then add 25g of DDAC antibacterial agent to the spinning solution, and stir at a constant speed until the polymer is completely dissolved;

[0044] (2) Put the spinning solution described in step (1) in the liquid supply device of the electrostatic spinning machine, adjust the spinning voltage to 45KV, and the spinning distance to 18cm;

[0045] (3) Combine the reinforced ES hot air nonwoven fabric (PE / PP, with an area density of 25g / m 2 , Provided by the Nonwoven Materials a...

Embodiment 2

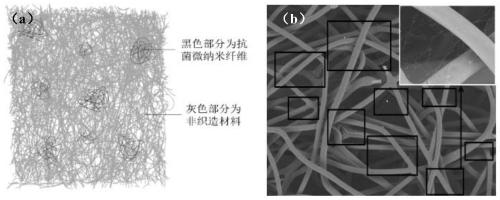

[0048] (1) Equipped with a spinning solution containing antibacterial agents: polyacrylonitrile (PAN, relative molecular mass 85000), Shanghai Macleans Biochemical Technology Co., Ltd.; N,N-dimethylformamide (DMF, analytical pure), Sinopharm Group Chemical Reagent Co., Ltd.; Didecyl Dimethyl Ammonium Chloride (DDAC, analytical grade), Shanghai Aladdin Biochemical Technology Co., Ltd.; add 65g of PAN solid powder to 500mL of DMF solution at 25°C Stir quickly until the spinning solution is clear and transparent, then add 25g of DDAC antibacterial agent to the spinning solution, and stir at a constant speed until the polymer is completely dissolved;

[0049] (2) Put the spinning solution described in step (1) in the liquid supply device of the electrostatic spinning machine, adjust the spinning voltage to 45KV, and the spinning distance to 18cm;

[0050] (3) Combine the reinforced ES hot air nonwoven fabric (PE / PP, with an area density of 25g / m 2 , Provided by the Nonwoven Materials a...

Embodiment 3

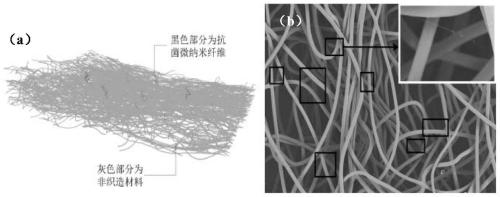

[0053] (1) Equipped with a spinning solution containing antibacterial agents: polyacrylonitrile (PAN, relative molecular mass 85000), Shanghai Macleans Biochemical Technology Co., Ltd.; N,N-dimethylformamide (DMF, analytical pure), Sinopharm Group Chemical Reagent Co., Ltd.; Didecyl Dimethyl Ammonium Chloride (DDAC, analytical grade), Shanghai Aladdin Biochemical Technology Co., Ltd.; add 65g of PAN solid powder to 500mL of DMF solution at 25°C Stir quickly until the spinning solution is clear and transparent, then add 25g of DDAC antibacterial agent to the spinning solution, and stir at a constant speed until the polymer is completely dissolved;

[0054] (2) Put the spinning solution described in step (1) in the liquid supply device of the electrostatic spinning machine, adjust the spinning voltage to 50KV, and the spinning distance to 17cm;

[0055] (3) The unreinforced non-woven web made of ES fibers (PE / PP, length 38mm, linear density 2.93dtex, provided by the Nonwoven Material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com