Preparation method of dipeptide-bacterial cellulose membrane

A technology of bacterial cellulose membrane and bacterial cellulose, which is applied in the field of preparation of dipeptide-bacterial cellulose membrane, can solve the problems of poor biodegradability, hinder the application of materials, etc., and achieves low cytotoxicity, low cost, and the ability to promote cell differentiation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

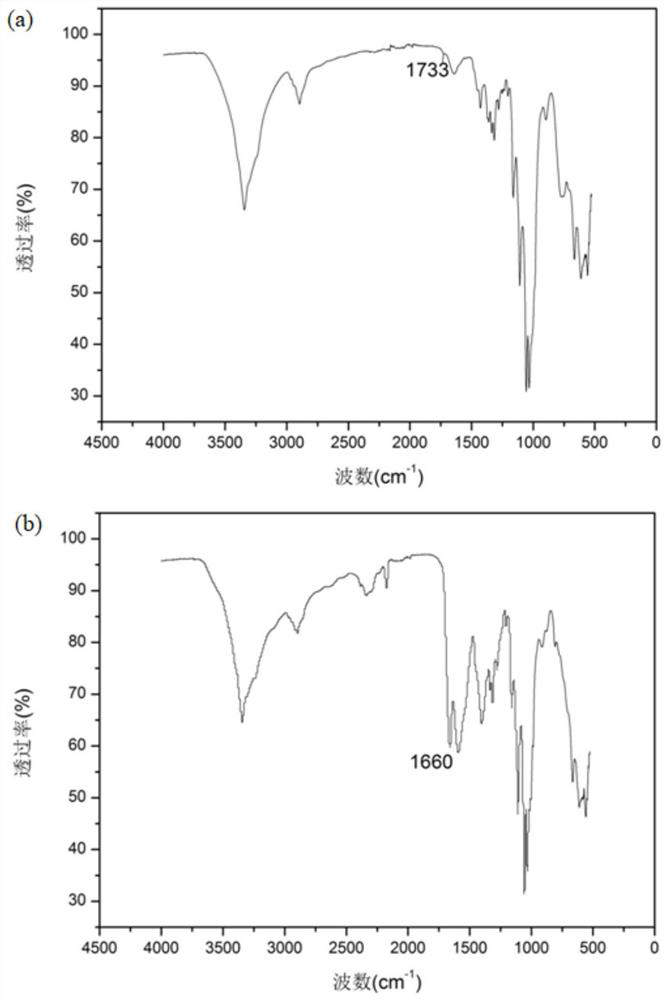

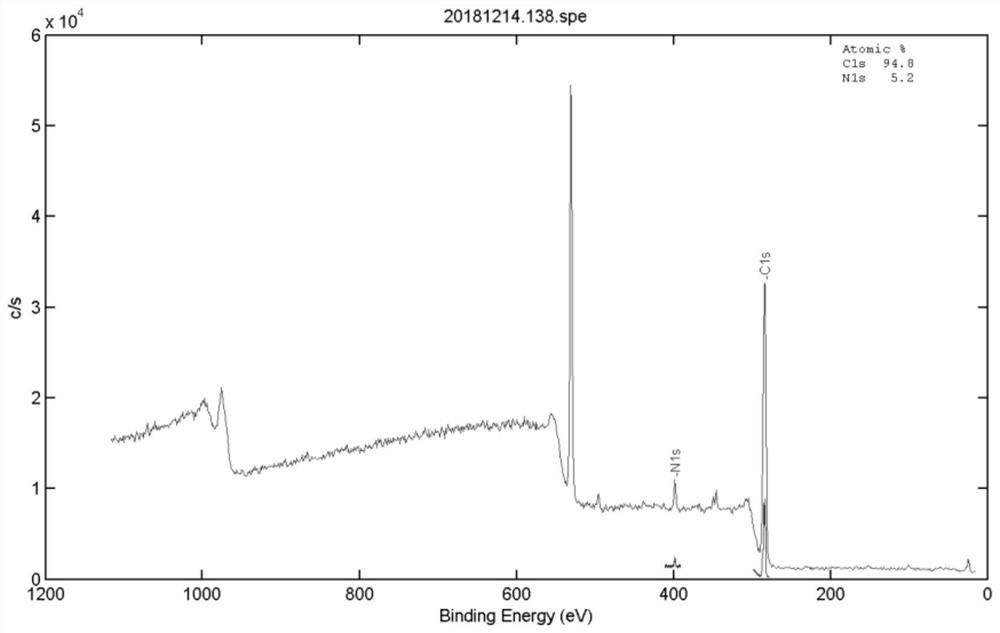

[0021] The preparation of dialdehyde BC refers to [Jin X, Xiang Z, Liu Q, et al. Polyethyleneimine-Bacterial Cellulose Bioadsorbent for Effective Removal of Copper and LeadIons from Aqueous Solution [J]. Bioresource Technology, 2017: S0960852417313779.].

[0022] The formula of Acetobacter xylinum fermentation medium in the existing laboratory (w / v, g / 100ml): glucose 2.25, sucrose 2.75, peptone 1.00, yeast extract powder 0.75, ammonium sulfate 0.10, potassium dihydrogen phosphate 0.50, magnesium sulfate 0.07 , calcium lactate 0.02, glacial acetic acid 0.15, citric acid 0.06, sodium carboxymethylcellulose 0.04, adjust pH=6.0, inoculate Acetobacterxylinum NUST 4.2 after high temperature sterilization.

[0023] F-12 medium formula: 84% F-12 medium, 15% fetal bovine serum, 1% vmj double antibody / 100F-12 medium.

Embodiment 1

[0025] Preparation of dialdehyde BC:

[0026] Wet BC film (water content 98.5%) was cut into 1cm×1cm strips, placed in 90mL distilled water, added 0.21g sodium periodate, mixed under magnetic stirring at 150r / min, at room temperature and under dark conditions for 2 days. After the reaction, the dialdehyde BC was filtered and washed with distilled water until the pH was neutral. The purified dialdehyde BC is obtained.

[0027] Preparation and purification of dipeptide-bacterial cellulose membrane:

[0028] Take the purified dialdehyde BC, put it in 80mL distilled water, add 0.2g L-glycerin-glutamic dipeptide, 0.21g sodium cyanoborohydride, adjust the pH to 5.8-6.0 with HCl, and stir at room temperature and 150r / min React for 6 hours. The prepared dipeptide-bacterial cellulose membrane was taken out, filtered with distilled water and washed until the pH was neutral.

Embodiment 2

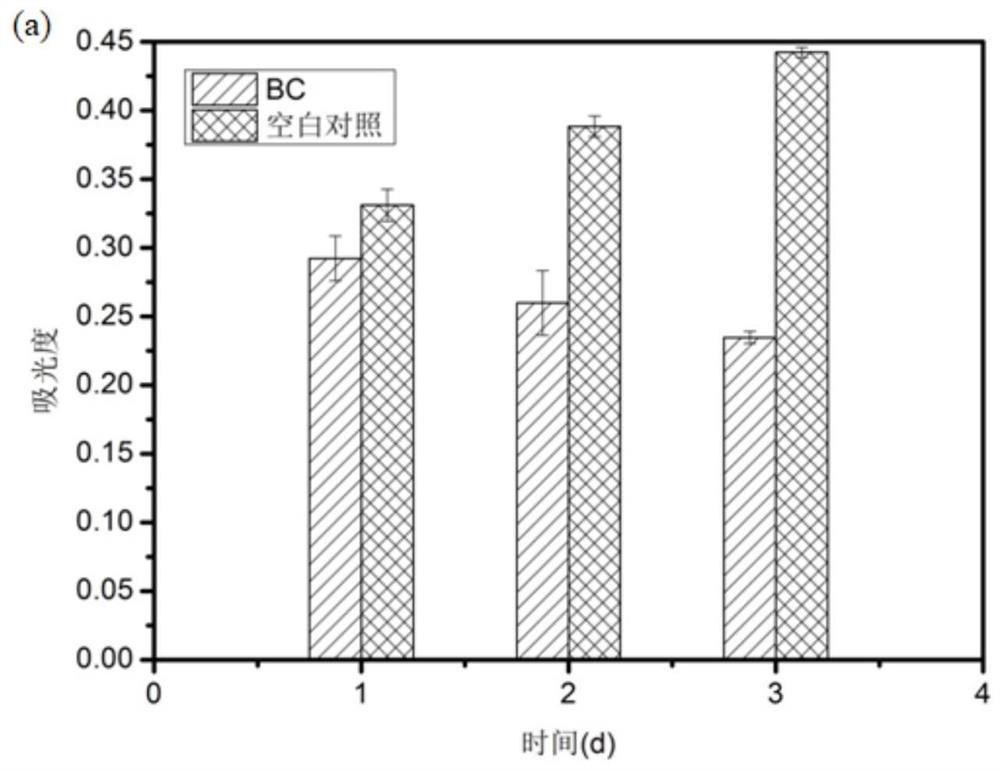

[0030] MTT test experiment:

[0031] Step 1. Spread the hydrogel sheet in a 96-well plate, soak it in F-12 medium for 4 hours, add 200ul to each well, and place it at 37°C, 5% CO 2 in the incubator;

[0032] Step 2, after sucking off the medium with a pipette gun, insert 5000 cells into each well of the wells containing the material and the wells of the parallel group, and put them into the incubator for culture;

[0033] Step 3, take out the corresponding well plate after 24 hours, add 10ul of MTT to each well, and incubate in the incubator;

[0034] Step 4. After 4 hours, use a syringe with a needle to absorb the liquid in the orifice plate, add 150ul DMSO to each well, and put it into a microplate reader to measure the absorbance;

[0035] Step 5: Shake the microplate reader for 30s to fully dissolve the crystal violet, then take the hydrogel sheet out of the well, detect with a wavelength of 490nm, and record the value.

[0036] Step 6, repeat steps 3-5 at 48h and 72h. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com