Boiler combustion implicit generalized predictive control method based on PSO algorithm

A generalized predictive control and boiler combustion technology, applied in the direction of adaptive control, comprehensive factory control, general control system, etc., can solve the problems of large inertia of boiler combustion system, easy model mismatch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

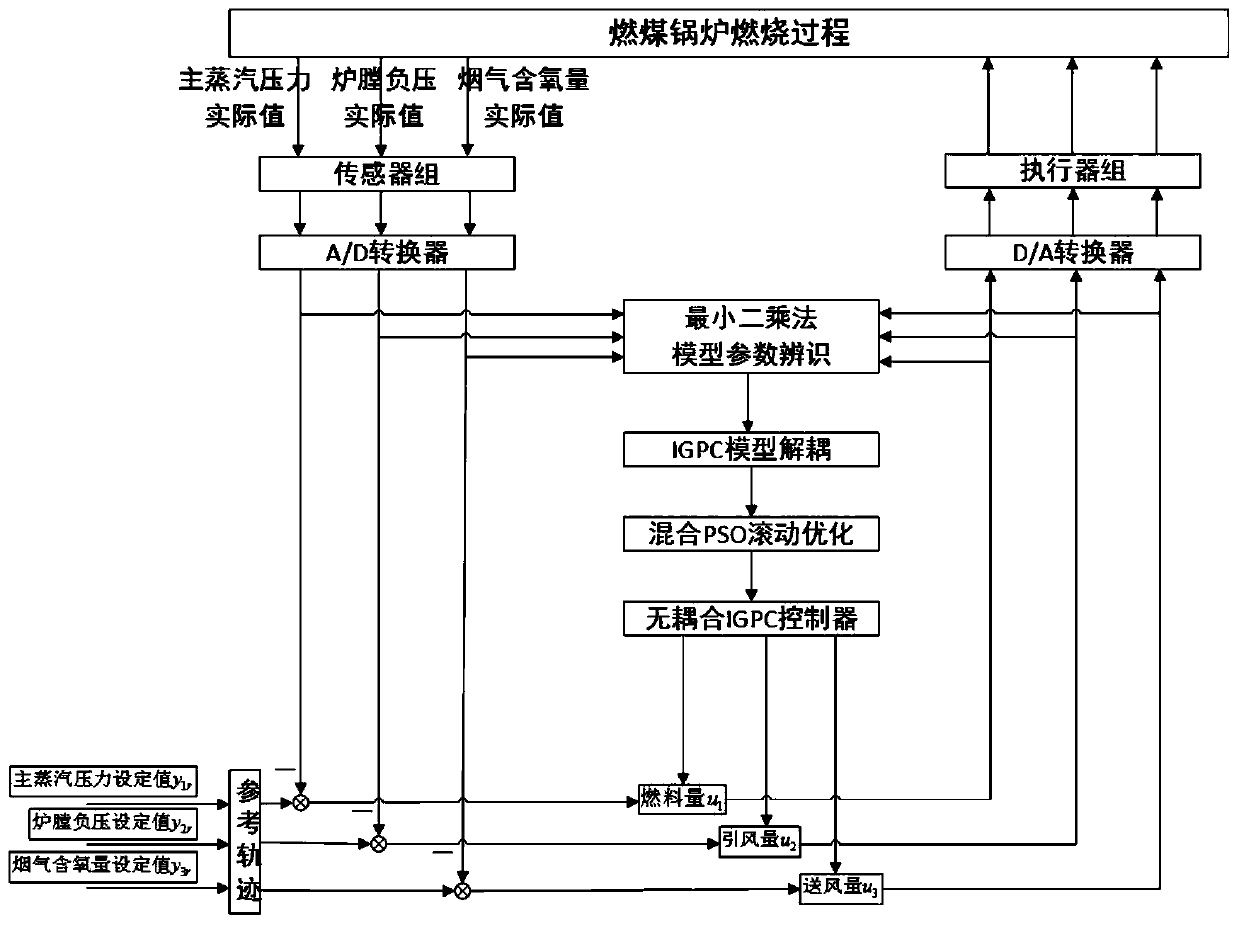

[0096] Such as figure 1As shown, the embodiment of the present invention provides a boiler combustion control system based on improved IGPC decoupling control. The control system includes a sensor group, an A / D converter, a D / A converter, an actuator group, and a boiler combustion controller. The system detects the main steam pressure, furnace negative pressure and flue gas oxygen content of the boiler combustion process through sensors, and converts them into digital signals through the A / D converter, and optimizes the boiler combustion control method through the improved multivariable implicit generalized predictive control method Calculate the required fuel volume, air supply volume and induced air volume, convert it into an analog signal through the D / A converter, and directly control the actuator group to control the main steam pressure ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap