Method of producing (meth)acrylic acid or ester thereof

A manufacturing method and technology of acrylic acid, applied in the field of manufacturing acrylic acid or its ester acrylic acid "), can solve the problems of low density, device clogging, high polymerization, etc., and achieve the effects of improving recovery rate, preventing clogging, and improving vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

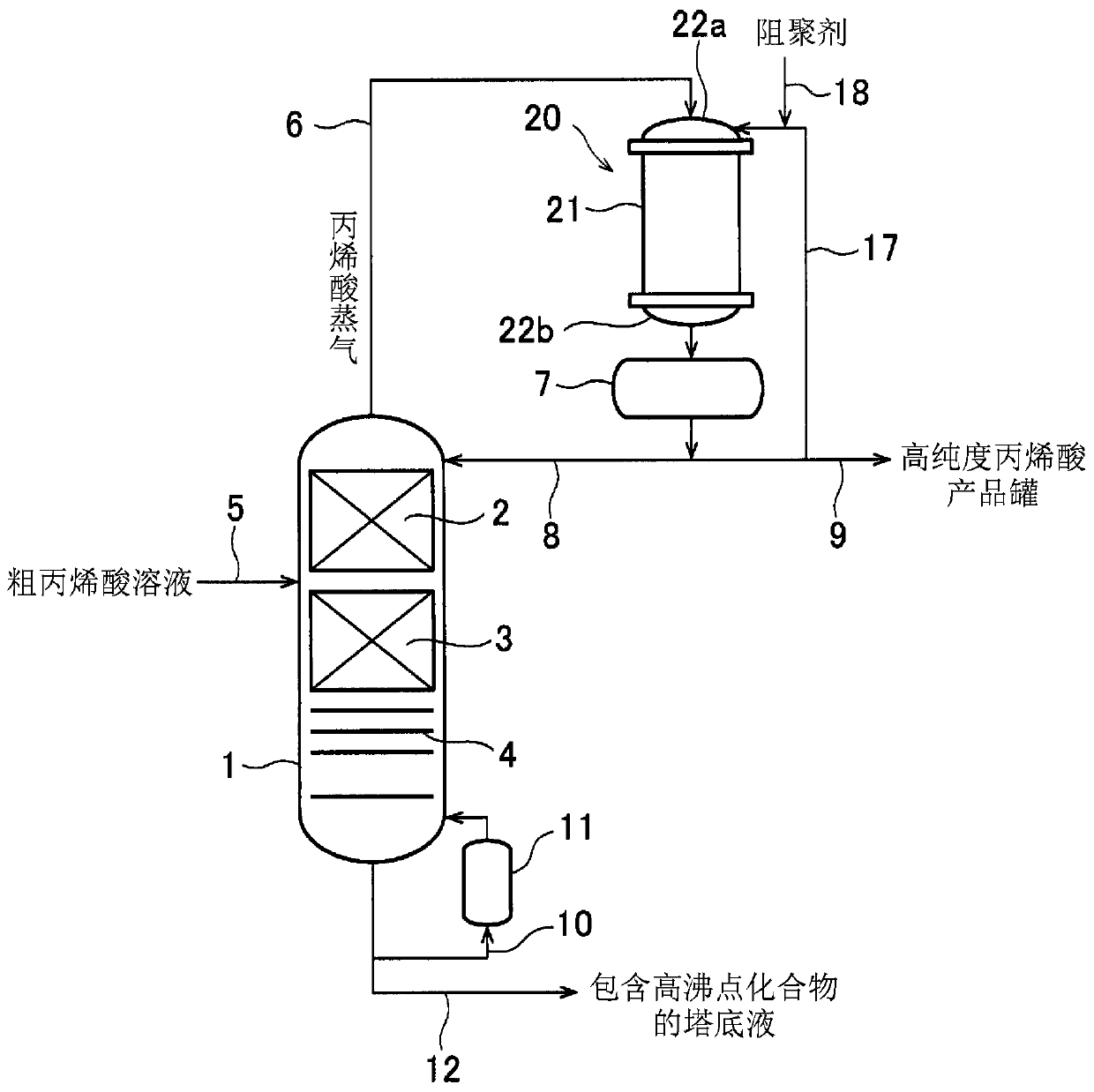

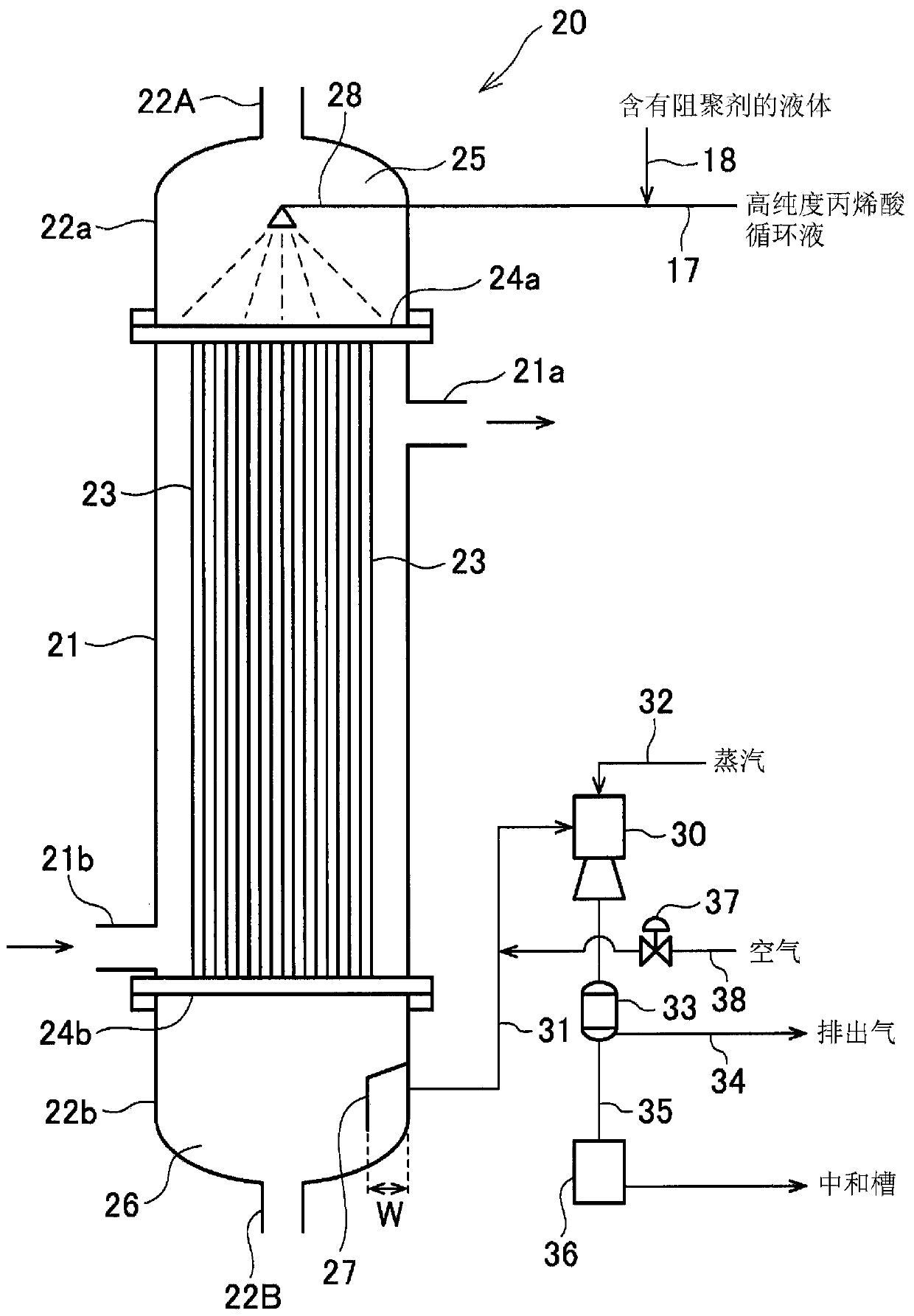

[0140] Using propylene as a raw material, the crude acrylic acid obtained through the reaction step of catalytic gas phase oxidation reaction and the purification step is supplied to figure 1 In the shown distillation column 1, the distillation of acrylic acid is carried out continuously. Assuming that the tower top pressure of distillation tower 1 is 2.4kPaA, and the reflux ratio is 1.2, the acrylic acid vapor distilled from the tower top is supplied to figure 2 In the vertical shell and tube heat exchanger 20 of the shown structure.

[0141] A device having 225 SUS304 heat transfer tubes with an inner diameter of 1 inch was used as the vertical shell-and-tube heat exchanger 20 . The supply temperature of the cooling water is 15-19°C, and the temperature of the condensed high-purity acrylic acid is 30-33°C. About 5 to 10% by mass of the condensate is circulated to the receiving chamber 25 side. An acrylic acid solution of hydroquinone monomethyl ether was added to this ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com