A heat-not-burn tobacco sheet

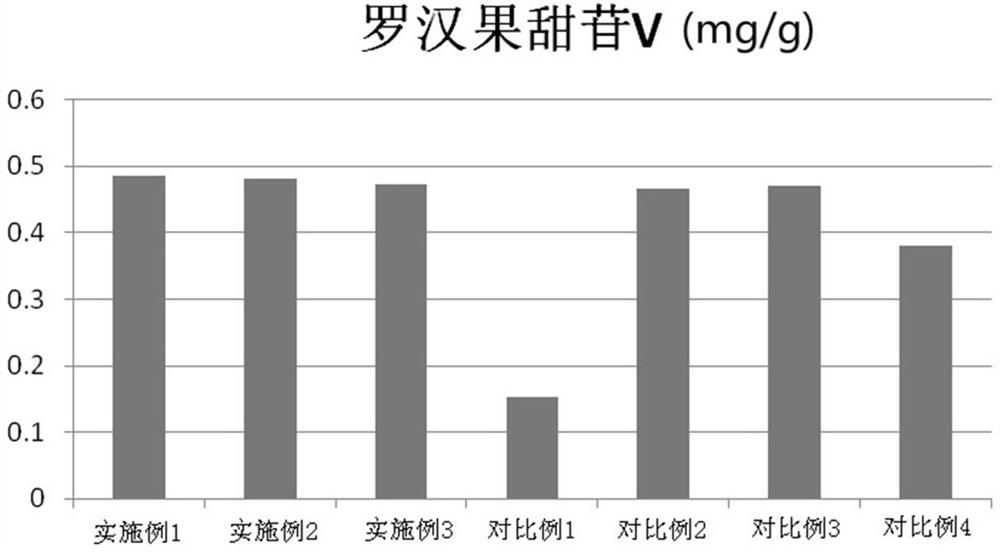

A heat-not-burn and tobacco flake technology, which is applied in the fields of tobacco, tobacco processing, and tobacco preparation, can solve the problems of slight astringency, poor coordination of tobacco, and insufficient sweetness, etc., and achieve outstanding flavor and distinct sweetness , Sweet and rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

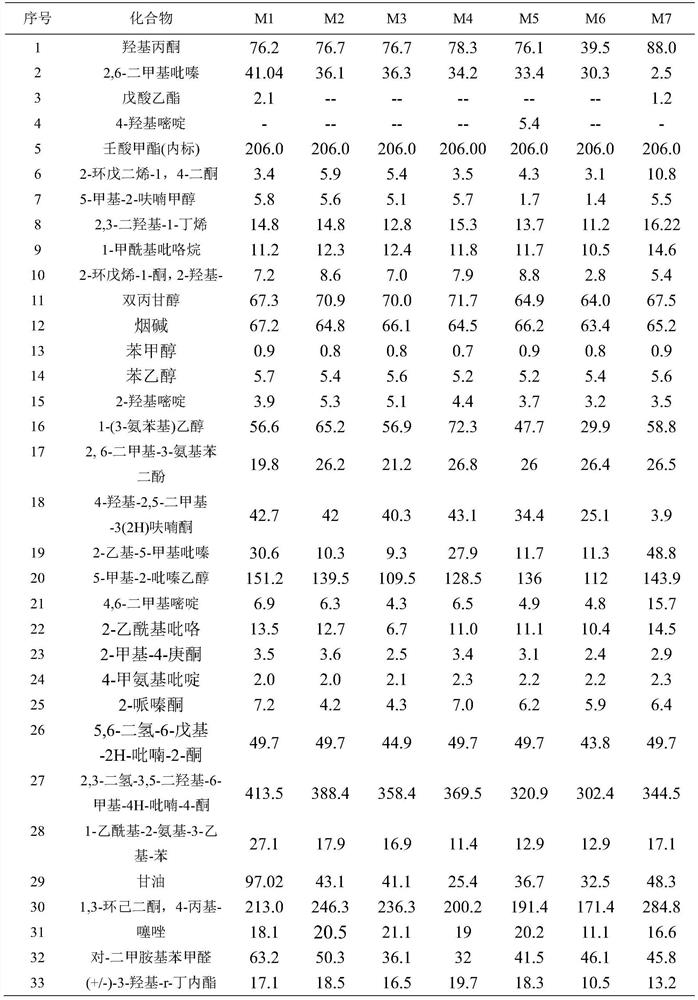

Embodiment 1

[0039] Prepare heating without burning tobacco flakes as follows.

[0040] (1) Take 1G drying tobacco extract, 1G fragrant smoke extract, 2G sweet potato acoustic treatment, 95 ° C microwave ultrasonic treatment, 95 ° C microwave ultrasound treatment, 95 ° C microwave ultrasound treatment 4 h, obtained by microwave treatment Frozen Rhonese.

[0041] (2) Make the lyophilized roller fruit after microwave treatment, dry distillation at 250 ° C, fractional A and dry distillate;

[0042] (3) In the dry distillate, 400 ml of petroleum ether extraction, filtration concentration, extract B and Luo Hanzi substrates;

[0043] (4) Will extract the remaining Luo Hansang raw material to dry powder, with Yunnan tobacco powder (middle smoke), Zimbabwei tobacco powder (upper smoke), Guizhou tobacco powder (lower smoke), Baoshan spices (upper smoke) according to 1 The proportion of 3: 2: 2: 2 is mixed, and the cellulose, the binder carboxymethylcellulose is mixed in a dry state, and the extract li...

Embodiment 2

[0051] The heating non-combustible tobacco sheet was prepared by the method described in Example 1, and the difference is that the dry distillation temperature is 300 ° C, and the other is the same as in Example 1.

Embodiment 3

[0053] The heating non-combustible tobacco sheet was prepared by the method described in Example 1, which is different from step (2), the dry distillation temperature is 350 ° C, and the other is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com