Heating and cooling method for thermal cycle adsorption separation device

A technology of adsorption separation and temperature rise and fall, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of uneven temperature distribution of separation columns and slow temperature rise and fall speed, and achieve improved stability and separation efficiency, The effect of fast heating and cooling speed and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

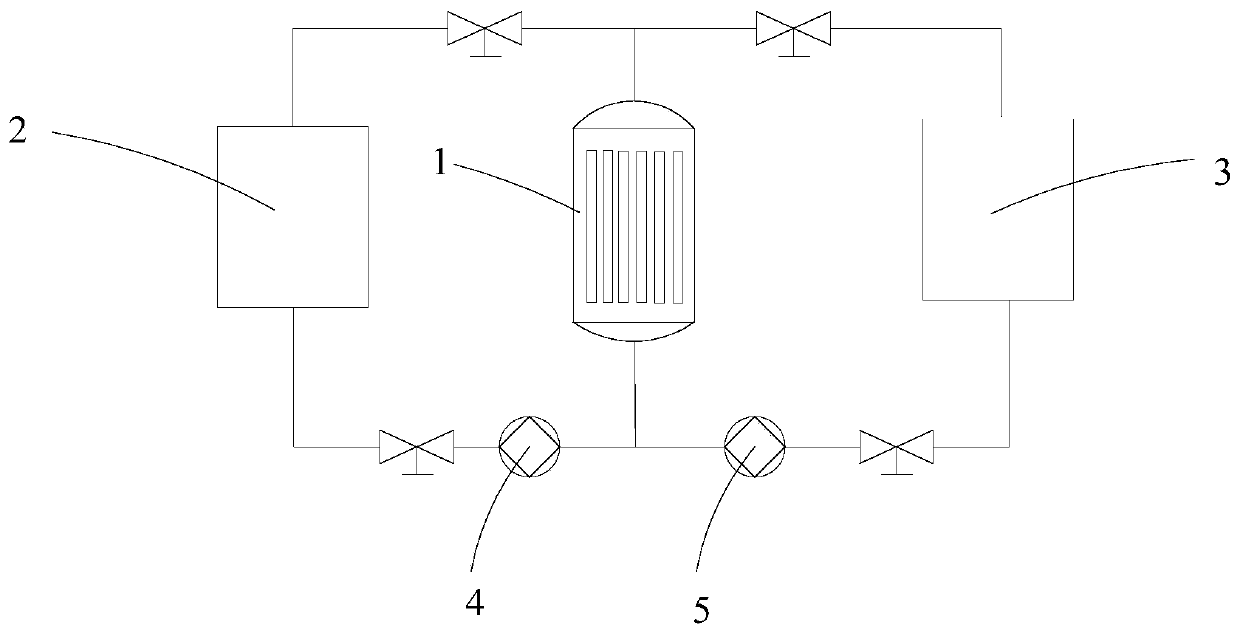

[0039] The invention relates to a heating and cooling method for a thermal cycle adsorption separation device. The separation column is immersed in a liquid medium, and the liquid medium is in a flowing state when the liquid medium and the separation column are exchanging heat.

[0040] The device for realizing the method includes a heat exchange pool, which is used to accommodate the separation column; the heat exchange pool is provided with an inlet and an outlet, and the liquid medium is injected into the heat exchange pool through a pump, and the liquid medium enters from the inlet of the heat exchange pool , flows out from the outlet of the heat exchange pool and flows in the heat exchange pool. Through the heat exchange between the liquid medium and the separation column, each part of the separation column is evenly heated.

[0041] When switching between heating and cooling is required, the temperature of the liquid medium can be raised or lowered by heating or cooling ...

Embodiment 2

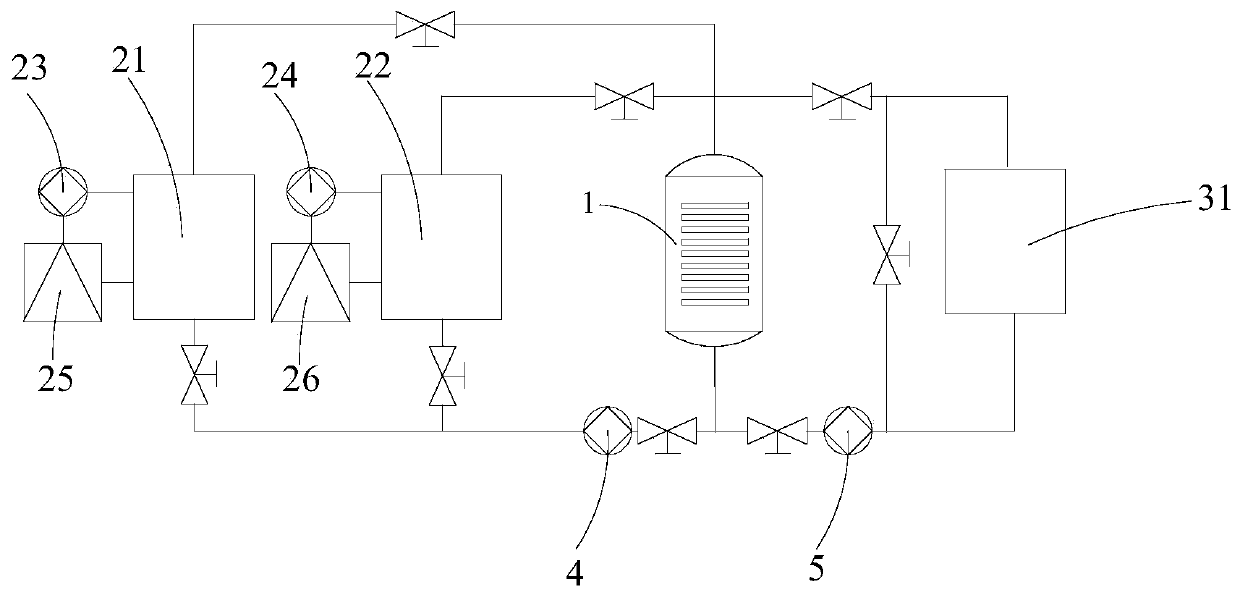

[0043] A heating and cooling method for a thermal cycle adsorption separation device. In this embodiment, the liquid medium includes a hot liquid medium and a cold liquid medium; Exchange: when the temperature of the separation column is lowered, the cold liquid medium exchanges heat with the separation column. Such as figure 2In the schematic diagram shown, the separation column is located in the heat exchange pool 1, the cold liquid medium 2 and the cooling pump 4 form a cooling component, and are connected to the heat exchange pool 1 through pipelines to form a cooling cycle; the hot liquid medium 3 and the temperature raising pump 5 A heating component is formed and connected to the heat exchange pool 1 through another pipeline to form a heating cycle. The cold liquid medium 2 is circulated in the cooling cycle to realize the cooling of the separation column, and the hot liquid medium 3 is circulated in the temperature raising cycle to realize the temperature rise of the...

Embodiment 3

[0049] The separation column described in this embodiment is a spiral separation column. The length of the helical separation column is longer, which is beneficial to the separation of hydrogen isotopes. At the same time, the heat capacity of the helical separation column is relatively high. Therefore using the figure 2 The shown apparatus implements the method.

[0050] Such as figure 2 As shown, the device includes a heat exchange pool 1, a cold cycle assembly and a heat cycle assembly. A spiral separation column is installed inside the heat exchange tank 1 . The heat exchange tank 1 is a pot-shaped body with upper and lower openings. The cold cycle assembly includes a first cold oil tank 21 and a second cold oil tank 22. The two cold oil tanks are connected to the cooling pump 4 through pipelines, and then connected to the heat exchange pool 1 to form two cold cycle systems. The two cold circulation systems are mutually backed up to meet the requirements of the spir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pour point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

| Pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com