Preparation method of single-component geopolymer cement

A geopolymer cement, a single-component technology, applied in the field of cement materials, can solve the problems of low comprehensive utilization rate of metal tailings, resource waste environment, tailings accumulation, etc., and achieve low price, energy saving and carbon emission reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The invention provides a method for preparing single-component geopolymer cement, comprising the following steps:

[0016] S1, obtain raw materials, and count SiO in said raw materials respectively 2 、Al 2 o 3 and the content of Ca-containing compounds to obtain the analysis results, wherein the raw materials are selected from metal tailings, feldspar, papermaking lime mud and cement kiln dust, etc. The main components are SiO 2 、Al 2 o 3 and industrial by-products of Ca-containing compounds. The Ca-containing compound is CaO and / or CaCO 3 , where CaCO 3 CaO can be obtained by high temperature calcination. Through the comprehensive utilization of solid waste such as metal tailings, on the one hand, it can reduce the environmental pressure caused by the stockpiling of tailings. efficient utilization and energy saving.

[0017] Further, in terms of mass percentage, in the metal tailings, the SiO 2 35% to 45%, the Al 2 o 3 5% to 8%, the CaO is 25% to 30%, and i...

Embodiment 1

[0031] A kind of single-component geopolymer cement preparation method provided by the present embodiment comprises the following steps:

[0032] (1) Preparation of admixtures: The composition of metal tailings, papermaking lime mud and feldspar is shown in Table 1. According to SiO in Table 1 2 、Al 2 o 3 The mass ratio of CaO and CaO is calculated by mass percentage, and the metal tailings, papermaking lime mud and feldspar are blended at 50%, 30% and 20% respectively to prepare the admixture. Among them, by mass percentage, in the admixture, SiO 2 35.6%, CaO 30.1%, Al 2 o 3 6.3%, SiO 2 and Al 2 o 3 The mass ratio is 5.65:1.

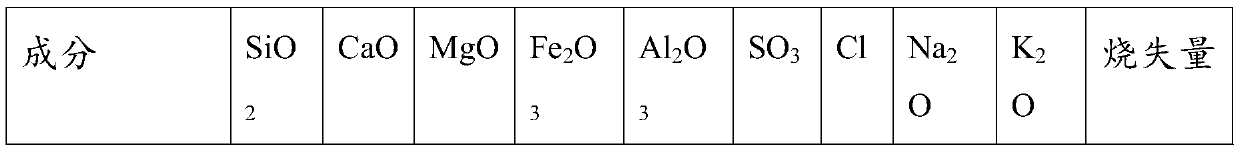

[0033] Table 1 Analysis results of metal tailings, papermaking lime mud and feldspar composition (mass ratio %)

[0034] Element SiO 2

CaO MgO Fe 2 o 3

Al 2 o 3

SO 3

Na 2 o

K 2 o

Loss on ignition metal tailings 41.0 28.6 4.0 8.4 6.7 3.1 0.2 0.2 7.8 Papermaking clay 2.1 ...

Embodiment 2

[0038] A kind of single-component geopolymer cement preparation method is provided in the present embodiment, differs from embodiment 1 in that:

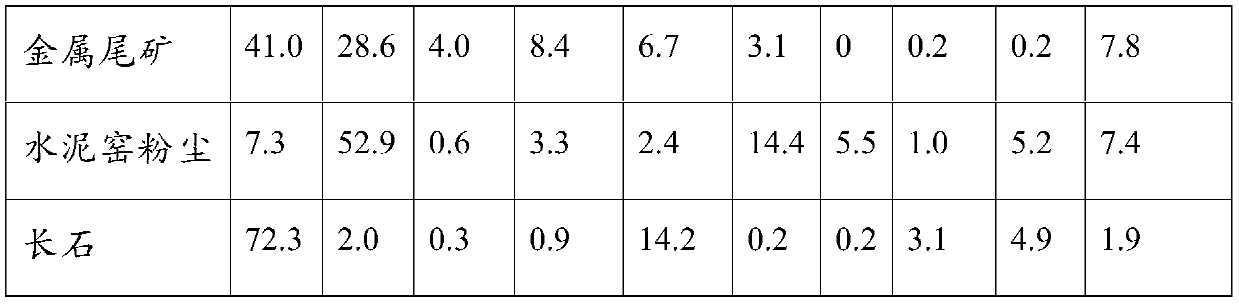

[0039] Preparation of admixtures in step (1): the composition of metal tailings, cement kiln dust and feldspar is shown in Table 2. According to SiO in Table 2 2 、Al 2 o 3 The mass ratio of CaO and metal tailings, papermaking lime mud and feldspar are blended at a mass ratio of 5:3:2 to prepare the admixture. Among them, by mass percentage, in the admixture, SiO 2 37.2%, CaO 30.6%, Al 2 o 3 6.9%, SiO 2 and Al 2 o 3 The mass ratio is 5.4:1.

[0040] Table 2 Analysis results of metal tailings, cement kiln dust and feldspar composition (mass ratio %)

[0041]

[0042]

[0043] The 28d cube compressive strength of the one-component geopolymer cement obtained by this embodiment is 45MPa, and the 28d cube compressive strength of this single-component geopolymer cement reaches No. 42.5 cement strength standard, and its 3d c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com