High-temperature-resistant geopolymer mortar and preparation method thereof

A technology of geopolymer and high temperature resistance, which is applied in the field of high temperature resistant geopolymer mortar and its preparation, and can solve problems such as low permeability, easy damage, and large internal vapor pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

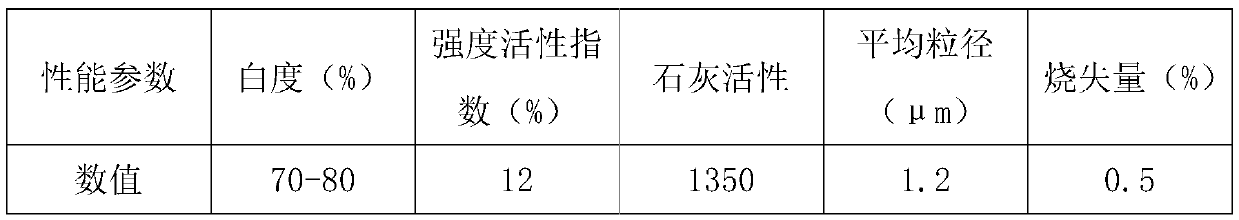

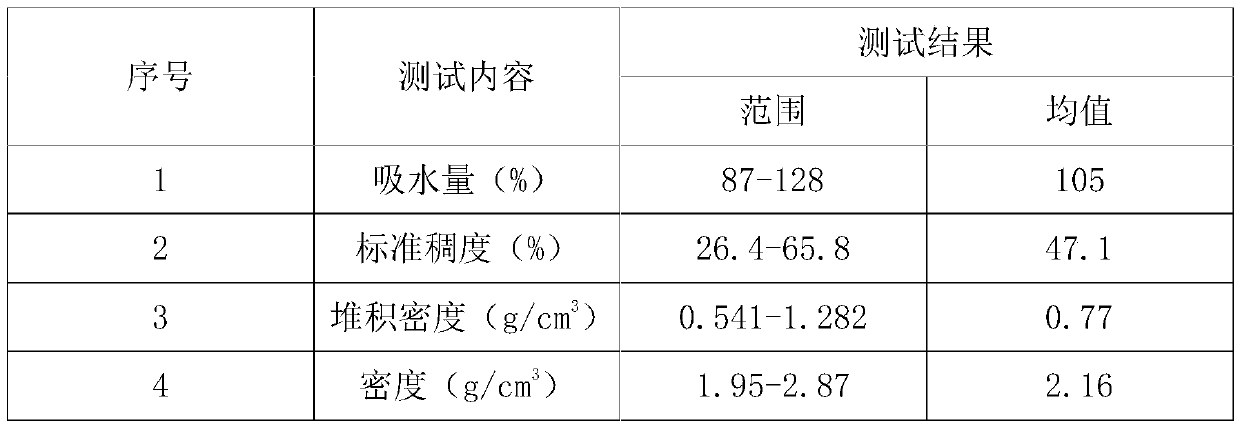

Method used

Image

Examples

Embodiment 1

[0042] Weigh raw materials, 500 parts of alkali activator, 400 parts of metakaolin, 150 parts of fly ash, 600 parts of quartz sand, nano-SiO 2 1 part, 0.2 parts of PVA fiber, 100 parts of water, 3 parts of water reducer, 1 part of graphene.

[0043] The preparation method of the high temperature resistant geopolymer mortar of the present embodiment is:

[0044] (1) Dissolve 0.5407g of p-phenylenediamine in 10mL of concentrated hydrochloric acid, stir, and ultrasonically obtain a white suspension, place it in an ice-salt bath with magnetic stirring to fully cool it, and dissolve NaNO 2 solution (0.7527g NaNO 2 dissolved in 4mL water) and NaBF 4 Solution (1.48g NaBF 4 Crystals were dissolved in 4mL water) placed in a refrigerator to cool below 0°C, and NaNO was added dropwise to the system 2 Solution, stirring while dripping, while using starch potassium iodide test paper to detect NaNO 2 Whether it is excessive, as the reaction progresses, the system gradually turns orange...

Embodiment 2

[0048] 510 parts of alkali activator, 430 parts of metakaolin, 180 parts of fly ash, 610 parts of quartz sand, nano-SiO 2 3 parts, 0.8 parts of PVA fiber, 110 parts of water, 3 parts of water reducer, 2 parts of graphene.

[0049] The preparation method of the high temperature resistant geopolymer mortar of the present embodiment is:

[0050] (1) Dissolve 0.5407g of p-phenylenediamine in 10mL of concentrated hydrochloric acid, stir, and ultrasonically obtain a white suspension, place it in an ice-salt bath with magnetic stirring to fully cool it, and dissolve NaNO 2 solution (0.7527g NaNO 2 dissolved in 4mL water) and NaBF 4 Solution (1.48g NaBF 4 Crystals were dissolved in 4mL water) placed in a refrigerator to cool below 0°C, and NaNO was added dropwise to the system 2 Solution, stirring while dripping, while using starch potassium iodide test paper to detect NaNO 2 Whether it is excessive, as the reaction progresses, the system gradually turns orange-red, when the star...

Embodiment 3

[0054] 510 parts of alkali activator, 430 parts of metakaolin, 180 parts of fly ash, 610 parts of quartz sand, nano-SiO 2 1 part, 0.2 parts of PVA fiber, 110 parts of water, 3 parts of water reducer, 2 parts of graphene.

[0055] The preparation method of the high temperature resistant geopolymer mortar of the present embodiment is:

[0056] (1) Dissolve 0.5407g of p-phenylenediamine in 10mL of concentrated hydrochloric acid, stir, and ultrasonically obtain a white suspension, place it in an ice-salt bath with magnetic stirring to fully cool it, and dissolve NaNO 2 solution (0.7527g NaNO 2 dissolved in 4mL water) and NaBF 4 Solution (1.48g NaBF 4 Crystals were dissolved in 4mL water) placed in a refrigerator to cool below 0°C, and NaNO was added dropwise to the system 2 Solution, stirring while dripping, while using starch potassium iodide test paper to detect NaNO 2 Whether it is excessive, as the reaction progresses, the system gradually turns orange-red, when the starc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com