Method for preparing environment-friendly brick from potassium feldspar tailings

A technology for potassium feldspar and environmental protection bricks, which is applied in the field of preparing environmental protection bricks by using potassium feldspar tailings, can solve the problems of insufficient utilization of potassium feldspar tailings, etc. Excellent dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

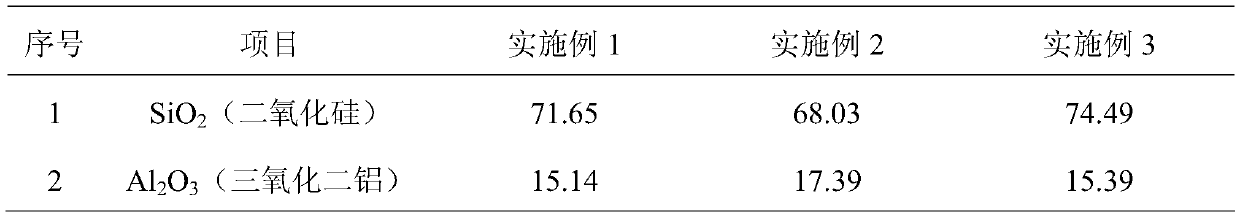

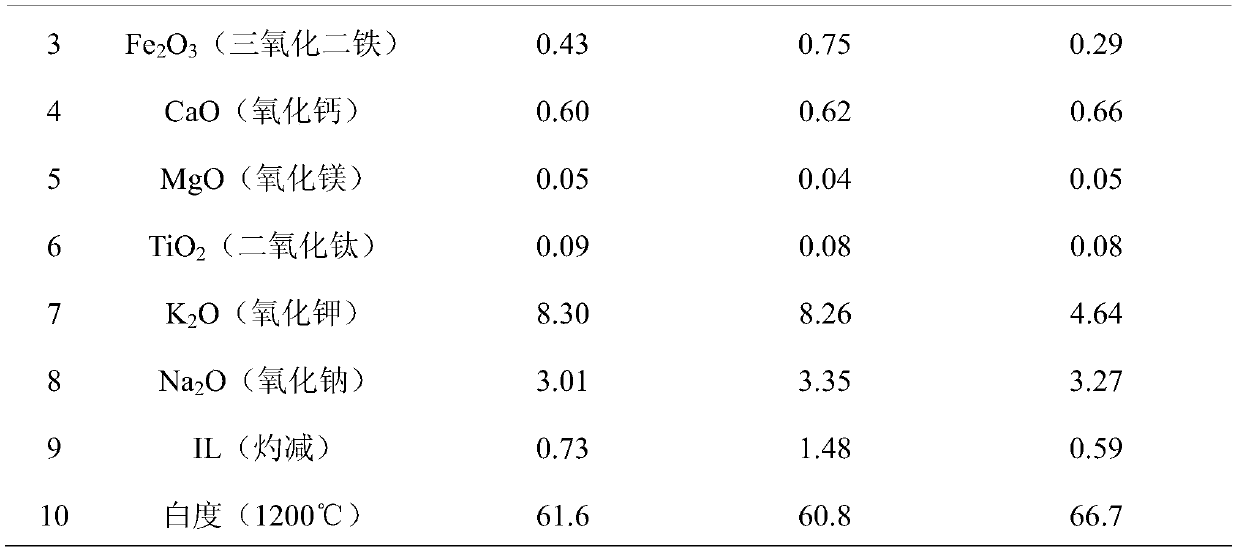

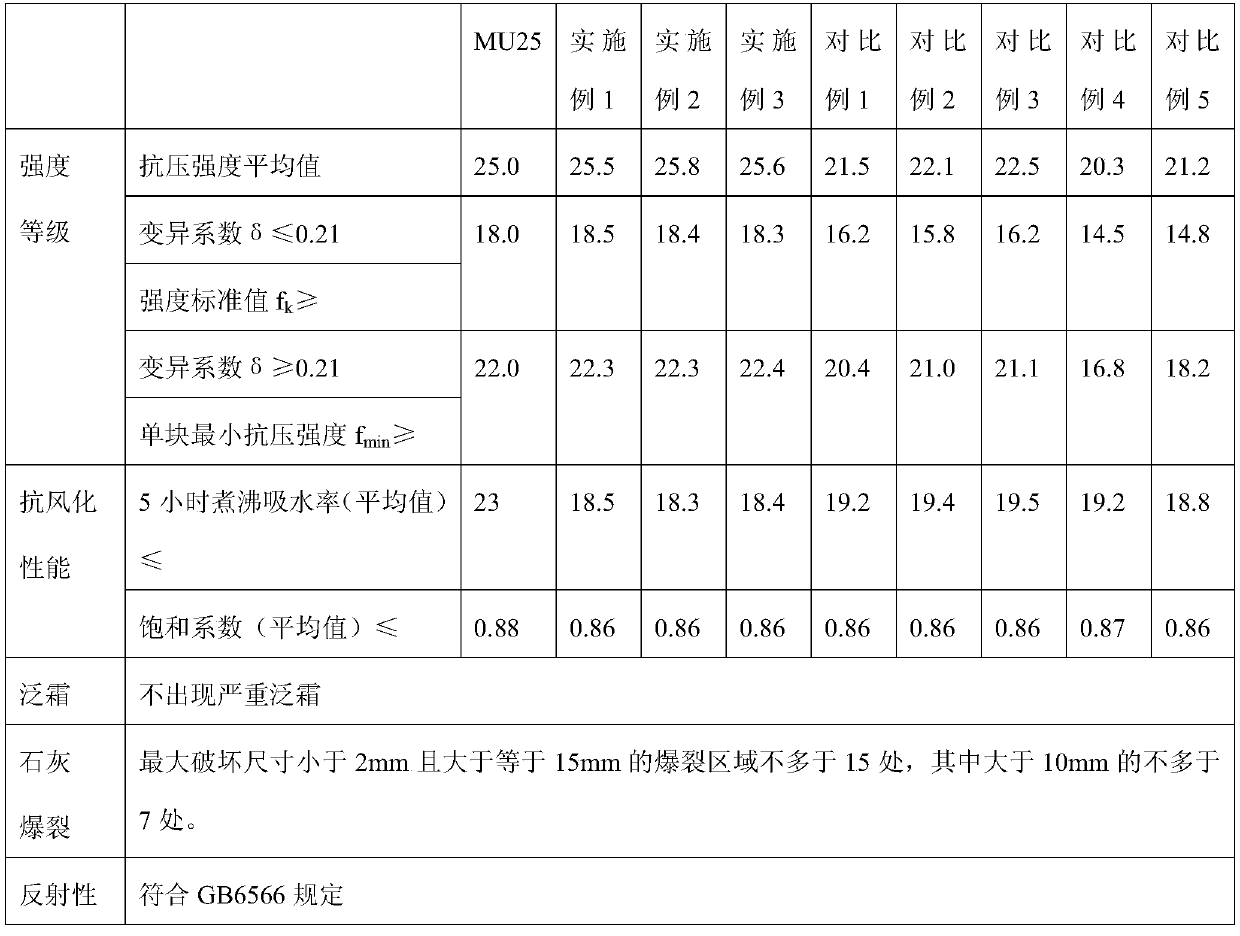

Embodiment 1

[0034] A method for preparing environmentally friendly bricks from potassium feldspar tailings, comprising the following technical steps:

[0035] 1) Treatment of potassium feldspar tailings: After the production of potassium feldspar, the tailings or tailings are sent to the ball mill, the ball-to-material ratio is 4:1, the initial slurry concentration is 60%, and propylene glycol-containing alginate is added dispersant, the amount of dispersant containing propylene glycol alginate is 0.5% of the mass of the abrasive, and it is finely ground to more than 80 mesh;

[0036] 2) Mixing for the first time: fully mixing the material obtained in the previous step with sludge with a moisture content of 70% to obtain sandy clay with a moisture content of 40%;

[0037] 3) mixing for the second time: the sandy clay and fly ash obtained in the previous step are mixed according to the mass ratio of 60%, 40%, and stirred evenly to form a mixture;

[0038] 4) Digestion: Add the second mixe...

Embodiment 2

[0047] A method for preparing environmentally friendly bricks from potassium feldspar tailings, comprising the following technical steps:

[0048] 1) Treatment of potassium feldspar tailings: After the production of potassium feldspar, the tailings or tailings are sent to the ball mill, the ball-to-material ratio is 5:1, the initial slurry concentration is 60%, and propylene glycol-containing alginate is added dispersant, the amount of dispersant containing propylene glycol alginate is 0.8% of the mass of the abrasive, and it is finely ground to more than 80 mesh;

[0049] 2) Mixing for the first time: fully mixing the material obtained in the previous step with sludge with a water content of 90% to obtain sandy clay with a water content of 40%;

[0050] 3) mixing for the second time: the sandy clay and fly ash obtained in the previous step are mixed by mass ratio of 70%, 30%, and stirred evenly to form a mixture;

[0051] 4) Digestion: Add the second mixed material after sti...

Embodiment 3

[0060] A method for preparing environmentally friendly bricks from potassium feldspar tailings, comprising the following technical steps:

[0061] 1) Treatment of potassium feldspar tailings: After the production of potassium feldspar, the tailings or tailings are sent to the ball mill, the ball-to-material ratio is 5:1, the initial slurry concentration is 60%, and propylene glycol-containing alginate is added dispersant, the amount of dispersant containing propylene glycol alginate is 0.6% of the mass of the abrasive, and it is finely ground to more than 80 mesh;

[0062] 2) Mixing for the first time: fully mixing the material obtained in the previous step with sludge with a water content of 80% to obtain sandy clay with a water content of 40%;

[0063] 3) mixing for the second time: the sandy clay and fly ash obtained in the previous step are mixed by mass ratio of 75%, 25%, and stirred evenly to form a mixture;

[0064] 4) Digestion: Add the second mixed material after sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com