Degradable paper cup and preparation method thereof

A paper cup and degradable film technology, applied in the field of paper cup manufacturing, can solve the problems of long time required for complete degradation of paper cups and slow degradation speed, and achieve the effects of accelerating the degradation speed, increasing the degradation speed, and accelerating the breakage of the main chain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

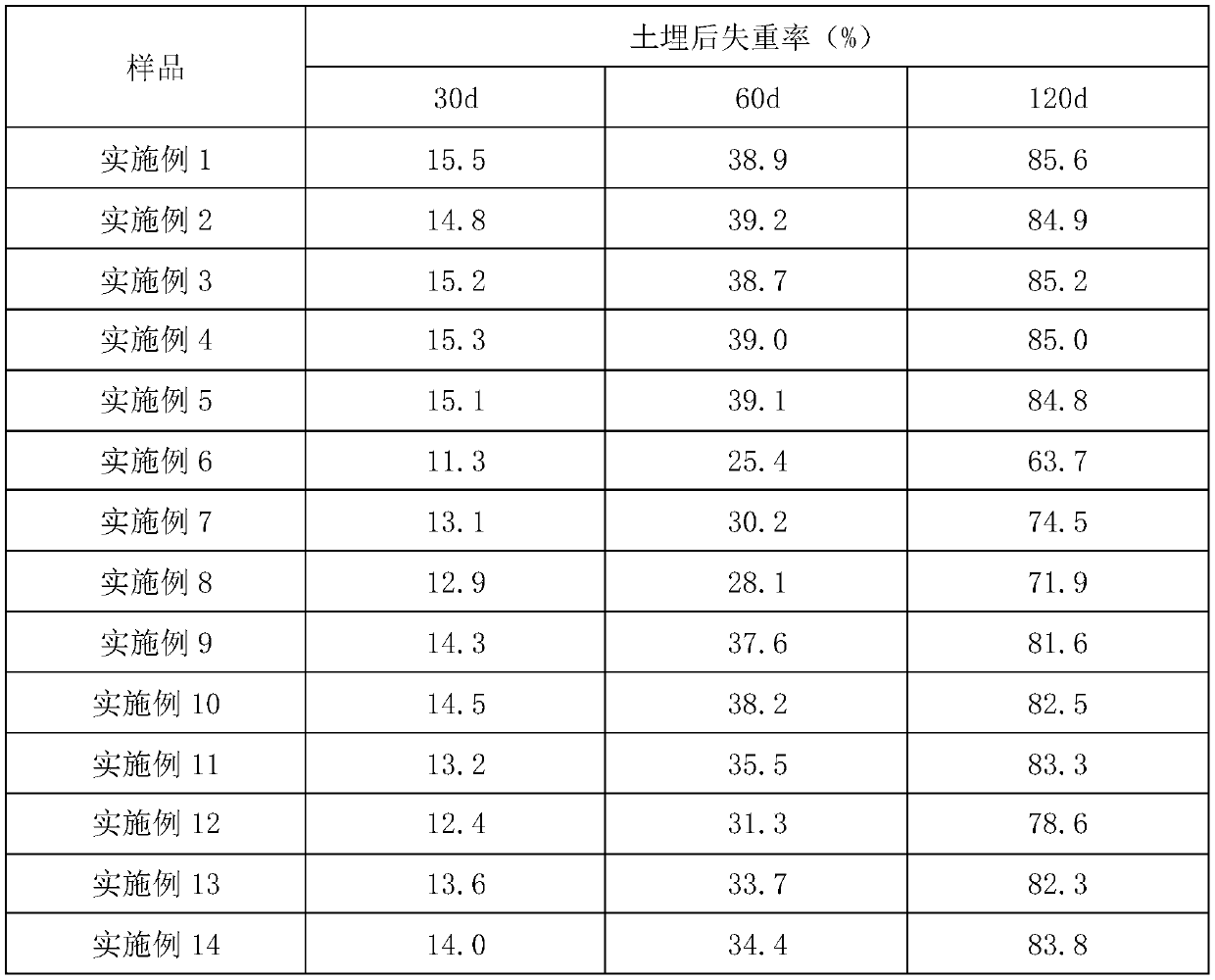

Embodiment 1

[0039] Embodiment 1 is a degradable paper cup disclosed by the present invention and its preparation method. The degradable paper cup includes a cup body and a degradable film coated on the surface of the cup body. The degradable film includes the following components by weight: polyethyl alcohol 80 parts of acid, 20 parts of tapioca starch, 15 parts of polyvinyl alcohol, 7.5 parts of acetic anhydride, 6 parts of trehalose, 4.5 parts of methyl orthoformate, 4 parts of photosensitive polypropylene particles, 3.5 parts of hydroxyethyl cellulose, epoxy type 2 parts of compatibilizer and 2 parts of organotin stabilizer;

[0040] The preparation method of photosensitive polypropylene particles is as follows: 1) Heating 10 parts by weight of ethyl acetate to 80°C, then adding 4 parts of atactic polypropylene to the hot solution of ethyl acetate, stirring until the atactic polypropylene is completely Dissolve to prepare A solution; 2) Add 2 parts by weight of ethanol into a clean con...

Embodiment 2

[0051] Example 2 is a degradable paper cup disclosed by the present invention and its preparation method. The difference from Example 1 is that the degradable film includes the following components in parts by weight: 70 parts of polyglycolic acid, 15 parts of tapioca starch , 10 parts of polyvinyl alcohol, 5 parts of acetic anhydride, 4 parts of trehalose, 3 parts of methyl orthoformate, 3 parts of photosensitive polypropylene particles, 2 parts of hydroxyethyl cellulose, 1 part of epoxy compatibilizer and organic tin 1 part of stabilizer.

Embodiment 3

[0052] Example 3 is a degradable paper cup disclosed by the present invention and its preparation method. The difference from Example 1 is that the degradable film includes the following components in parts by weight: 90 parts of polyglycolic acid, 25 parts of tapioca starch , 20 parts of polyvinyl alcohol, 10 parts of acetic anhydride, 8 parts of trehalose, 6 parts of methyl orthoformate, 5 parts of photosensitive polypropylene particles, 5 parts of hydroxyethyl cellulose, 3 parts of epoxy compatibilizer and organic tin 3 parts of stabilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com