A high ductility concrete energy dissipation filled wall frame structure and its construction method

A high-ductility concrete and frame structure technology, applied to walls, building components, building structures, etc., can solve problems such as loss, casualties and property, and achieve the effects of improving bearing capacity, convenient construction, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

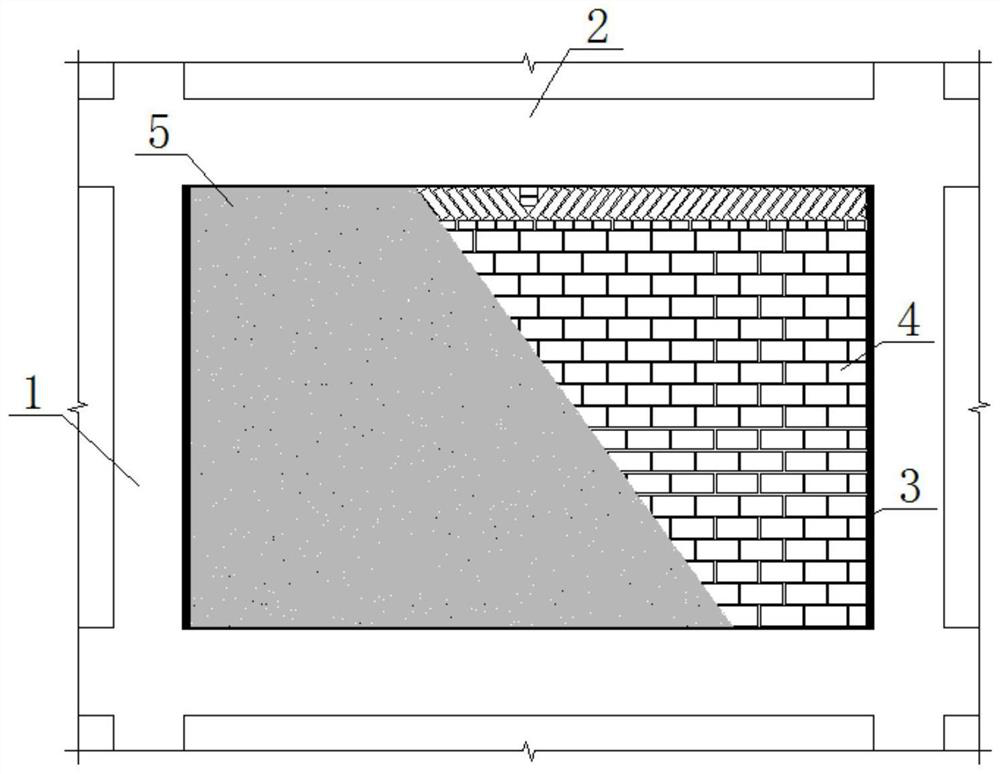

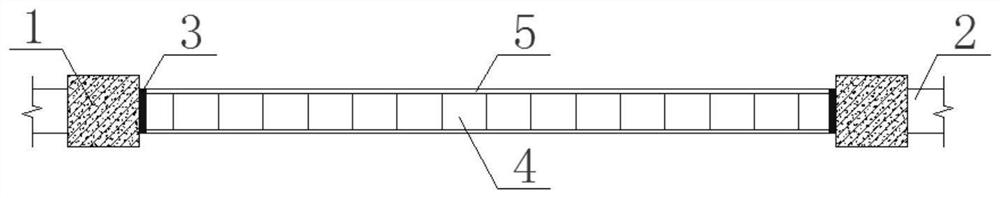

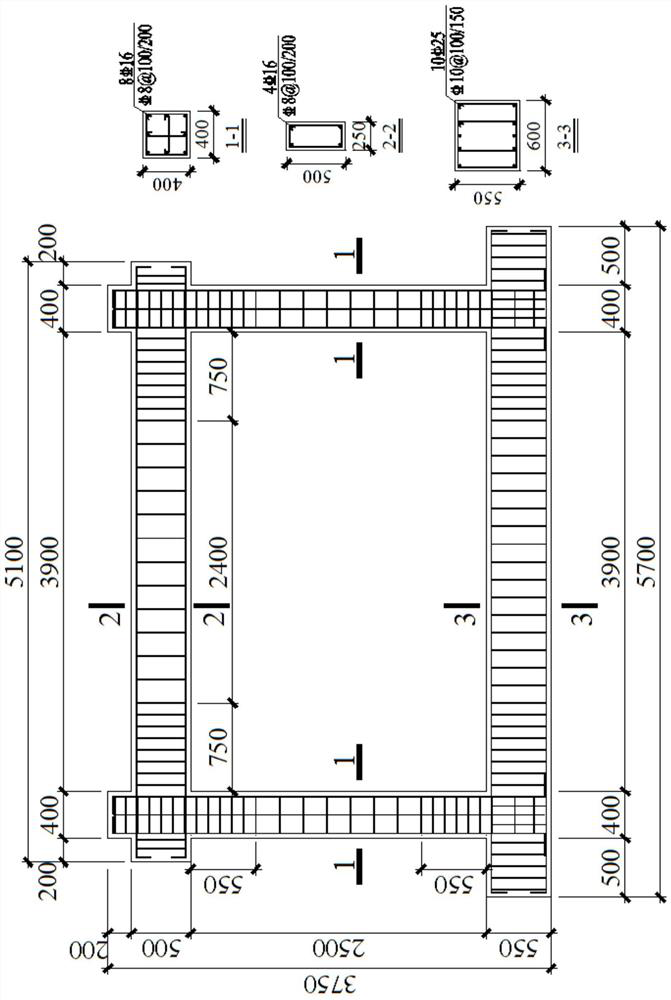

[0044] Such as figure 1 and 2 As shown, this embodiment provides a high ductility concrete energy-dissipating infill wall frame structure. There is a 15mm thick high ductility concrete surface layer 5, and the thickness of the polystyrene foam board flexible connection layer is 20mm;

[0045] The high ductility concrete formula used in this embodiment is: cement, fly ash, silica fume, sand, PE fiber, steel fiber and water, wherein, by mass ratio, cement: fly ash: silica fume: sand: water = 1: 0.1: 0.2: 0.76: 0.22, based on the total volume of cement, fly ash, silica fume, sand and water mixed uniformly, the volume content of PE fiber is 1%, and the volume content of steel fiber is 2 %;

[0046] The concrete used is C30 grade commercial concrete, the frame beams and column reinforcements are all HRB400 grade steel bars, the infill wall is made of MU5.0 sintered hollow bricks (240mm×200mm×115mm), the infill wall is built in the form of Transit, and the thickness of the mortar...

Embodiment 2

[0062] This embodiment is different from embodiment 1 in that:

[0063] This embodiment provides a high ductility concrete energy-dissipating infill wall frame structure with the following dimensions: the length of the frame column centerline is 5.0 m, the column height is 3.0 m, and the thickness of the infill wall is 200 mm; the outer surface of the infill wall 4 is coated with 10 mm Thick high-ductility concrete surface layer 5; the flexible material used is polyurethane foaming agent with a thickness of 10mm;

[0064] The formula of high ductility concrete is: cement, fly ash, silica fume, sand, PE fiber, steel fiber and water, among which, in terms of mass ratio, cement: fly ash: silica fume: sand: water = 1:0.2:0.28 : 0.76: 0.27, taking the total volume of cement, fly ash, silica fume, sand and water as the base, the volume content of PE fiber is 1.3%, and the volume content of steel fiber is 1.3%.

[0065] The structure of this embodiment is carried out above-mentioned...

Embodiment 3

[0070] This embodiment is different from embodiment 1 in that:

[0071] The centerline length of the frame column is 7.0m, the column height is 4.2m, and the thickness of the filling wall is 200mm. The outer surface of the filling wall 4 is coated with a 20mm thick high ductility concrete surface layer 5; the flexible material used is silicone glue with a thickness of 25mm.

[0072] The formula of high ductility concrete is: cement, fly ash, silica fume, sand, PE fiber, steel fiber and water, among which, in terms of mass ratio, cement: fly ash: silica fume: sand: water = 1:0.3:0.4 : 0.76: 0.32, taking the total volume of cement, fly ash, silica fume, sand and water as the base, the volume content of PE fiber is 1.5%, and the volume content of steel fiber is 2%.

[0073] The structure of this embodiment is carried out above-mentioned test, the result shows:

[0074] (1) The failure mechanism of the specimen is beam-hinge failure, the energy-dissipating filling wall and frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com