Device and method for characterizing dispersion state of CNTs in polymer composite material

A composite material and dispersed state technology, applied in the direction of analysis materials, measurement devices, test sample preparation, etc., to achieve the effect of short test cycle, good stability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

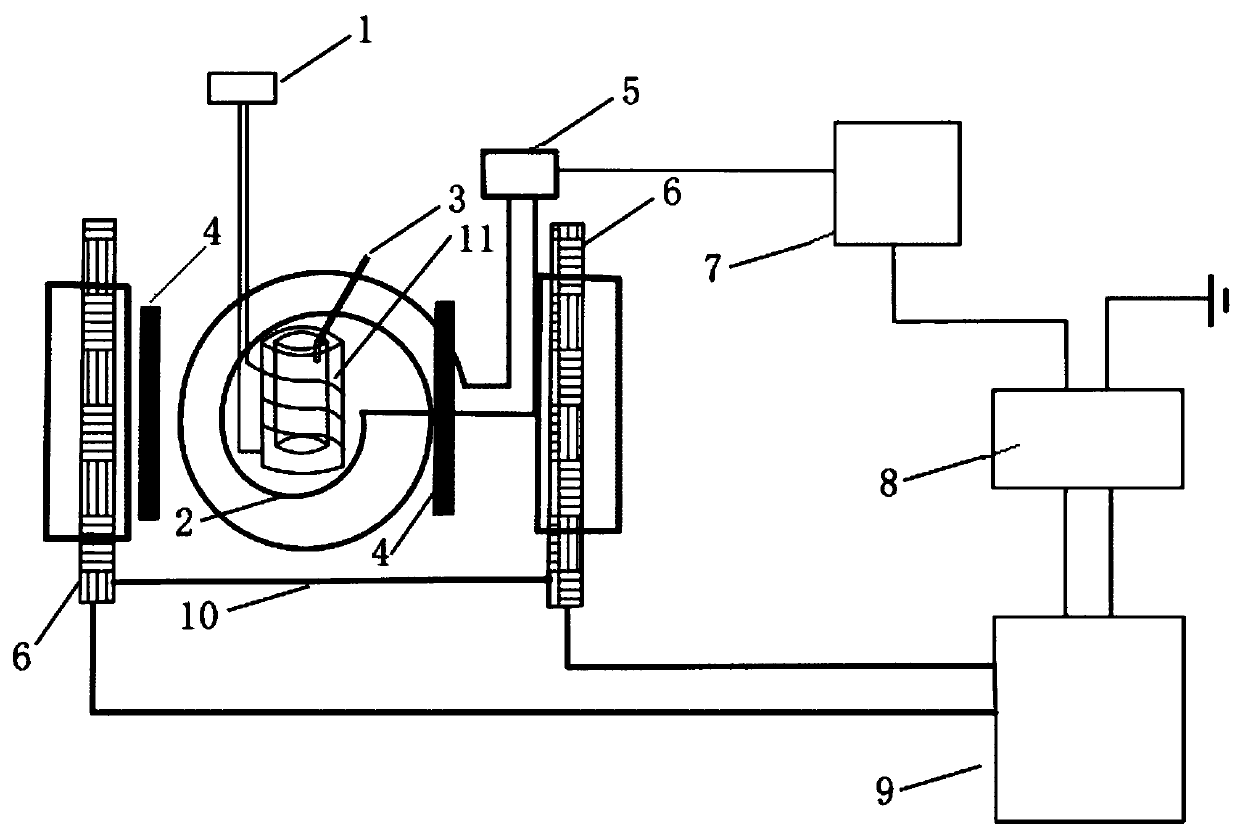

[0049] Embodiment 1 device

[0050] A device for characterizing the dispersed state of CNTs in a polymer composite material, comprising a sample tube 13, the sample tube 13 is arranged in a sample heating and holding device 11, the sample heating and holding device 11 is provided with an inert gas inlet 3, and the sample is heated and kept The device 11 is a cylindrical or hemispherical or pear-shaped hollow testing device, which can realize heating and heat preservation functions. The heating and heat preservation forms of the sample heating and heat preservation device 11 are electric heating of heat transfer oil in the jacket or electric heating of ceramic furnace tiles, preferably The heat conduction oil in the jacket is electrically heated.

[0051] Also be provided with the supersonic heating device of sample auxiliary heating, this supersonic heating device comprises supersonic generator 4, and this supersonic generator 4 is arranged around the sample heating and heat p...

Embodiment 2

[0054] Embodiment 2: Characterize the method for the dispersed state of CNTs in polymer composite material

[0055] (1) to test device inspection, content is the preparation of the natural rubber masterbatch sample of 15 parts of multi-wall array carbon nanotubes;

[0056] (2) Cut the sample into small pieces and put it into 1 / 2-2 / 3 of the ceramic sample tube to ensure that the test can scan to the sample position;

[0057] (3) Put the ceramic sample tube into the sample heating and heat preservation detection area, turn on the argon atmosphere, set the heating temperature to 170°C, turn on the ultrasonic heating device, and adjust the frequency to 45KHz;

[0058] (4) After heating the sample in the ceramic sample tube for 10 minutes to a fluid state, stop heating and keep warm;

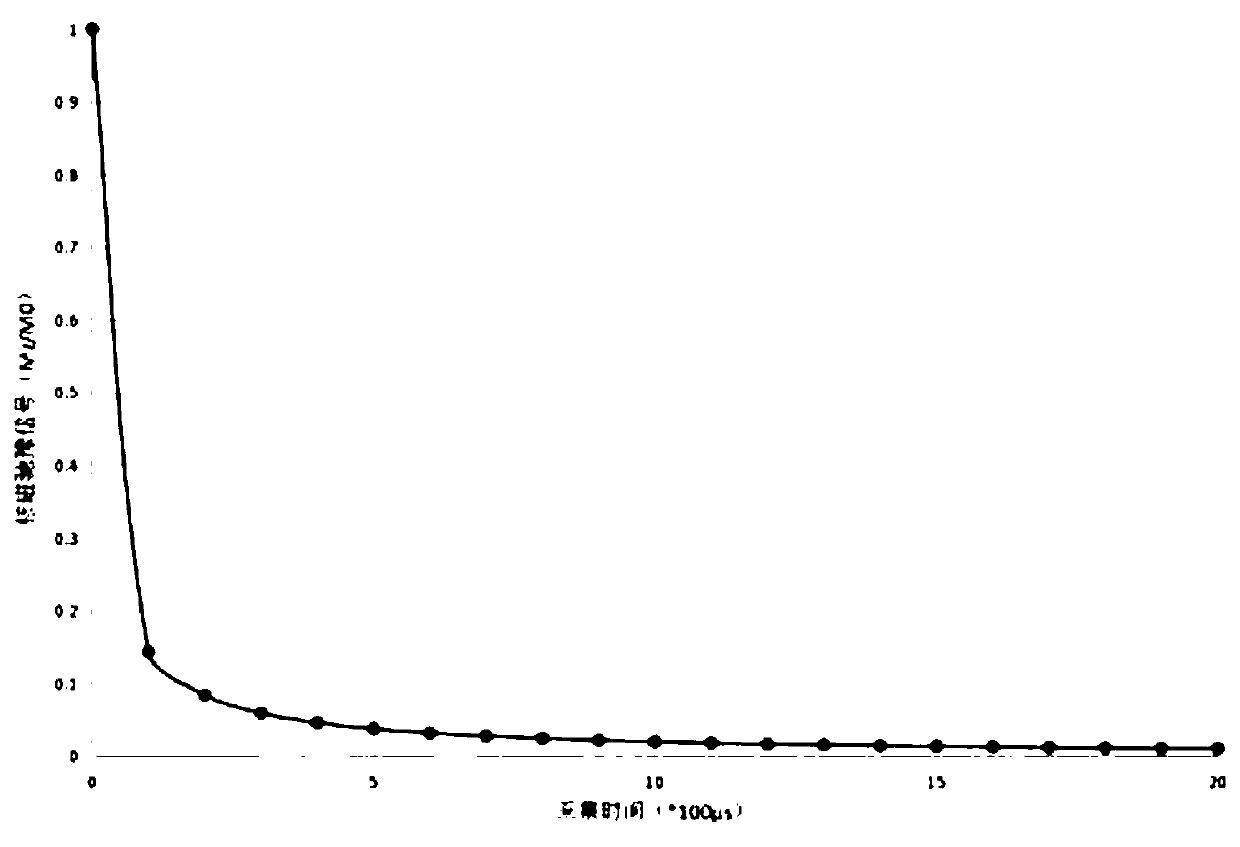

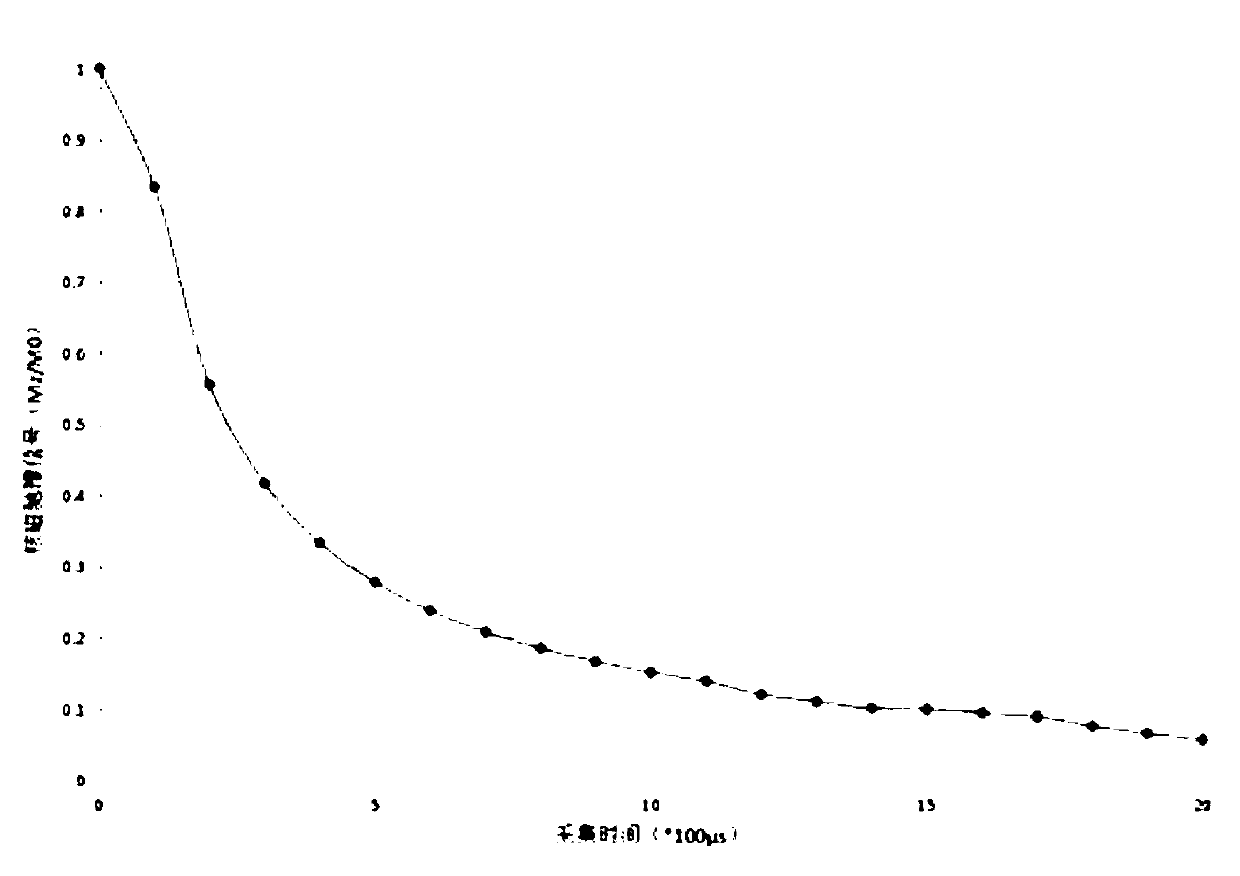

[0059] (5) After the sample is excited by the radio frequency transmitter, the signal and the signal amplifier are collected and amplified by the signal detector, and finally the graphics and parame...

Embodiment 3

[0063] Embodiment 3: the method for characterizing the dispersed state of CNTs in polymer composite material

[0064] (1) to test device inspection, single-walled carbon nanotube mass fraction is 0.3% styrene-butadiene rubber sample preparation;

[0065] (2) Cut the sample into small pieces of 5mm*5mm and put them into 1 / 2-2 / 3 of the ceramic sample tube to ensure that the test can scan to the sample position;

[0066] (3) Put the ceramic sample tube into the sample heating and heat preservation detection area, turn on the nitrogen atmosphere, set the heating temperature to 105°C, turn on the ultrasonic heating device, and adjust the frequency to 60KHz;

[0067] (4) After heating the sample in the ceramic sample tube for 8 minutes to a fluid state, stop heating and keep warm;

[0068] (5) After the sample is excited by the radio frequency transmitter, the signal and the signal amplifier are collected and amplified by the signal detector, and finally the graphics and parameters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com