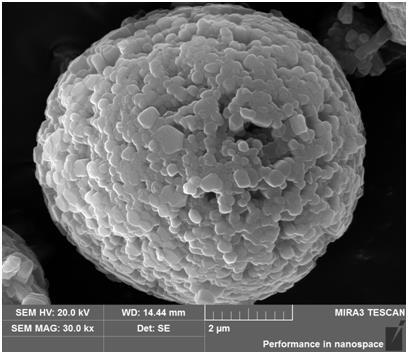

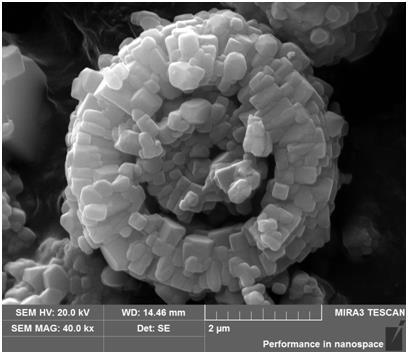

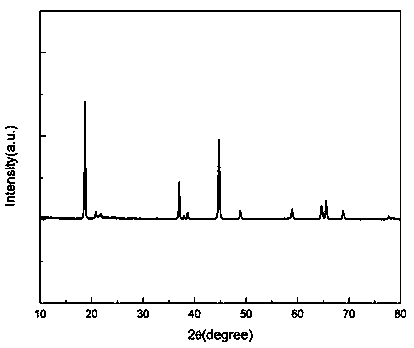

Preparation method of double-shell spherical lithium-rich layered oxide positive electrode material with radially arranged crystal grains

A positive electrode material and double-shell technology, which is applied in the field of lithium-ion battery electrode material preparation, can solve the problems of low first-cycle coulombic efficiency, insufficient high-rate charge-discharge capability, and poor material conductivity of lithium-rich layered oxide positive electrode materials. Achieve the effect of improving the high-current charge and discharge capacity, reducing the lithium diffusion resistance, and improving the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Prepare A solution, weigh manganese sulfate, nickel sulfate, cobalt sulfate according to the molar ratio Mn:Ni:Co=4:1:1, and dissolve in deionized water to prepare 2mol / L A solution; prepare B solution, weigh a certain A certain amount of precipitating agent and complexing agent are dissolved in deionized water, wherein the precipitating agent is sodium carbonate, the concentration of sodium carbonate solution is 2mol / L, the complexing agent is ammonia, and the concentration of ammonia is 0.1mol / L; polyvinylpyrrolidone is dissolved in Stir well in deionized water to prepare a 0.1 g / L polyvinylpyrrolidone solution. Co-precipitation is carried out in four stages: Stage 1, add A solution, B solution, and polyvinylpyrrolidone solution dropwise into deionized aqueous solution, control the pH value of the reaction system to 8.0, the stirring speed is 800 rpm, and the solution temperature is 50°C 1. Reaction for 12 hours; Stage 2, stop adding polyvinylpyrrolidone solution drop...

Embodiment 2

[0039] Prepare A solution, weigh manganese nitrate, nickel nitrate, and cobalt nitrate according to the molar ratio Mn:Ni:Co=5:1:1, and dissolve them in deionized water to prepare 0.1mol / L A solution; prepare B solution, weigh A certain amount of precipitating agent and complexing agent are dissolved in deionized water, wherein the precipitating agent is sodium bicarbonate, and the concentration of sodium bicarbonate solution is 0.1mol / L, and the complexing agent is ammonium bicarbonate, and the concentration is 0.01mol / L; Dissolve polyvinylpyrrolidone in deionized water and stir evenly to prepare a 0.5 g / L polyvinylpyrrolidone solution. Co-precipitation is carried out in four stages: stage 1, add solution A, solution B, and polyvinylpyrrolidone solution dropwise into the deionized aqueous solution, control the pH value of the reaction system to 6.0, the stirring rate is 300 rpm, and the solution temperature is 20°C , Reaction for 40 hours; Stage 2, stop adding polyvinylpyrrol...

Embodiment 3

[0043] Prepare A solution, weigh manganese formate, nickel formate, cobalt formate according to the molar ratio Mn:Ni:Co=4:1:1, and dissolve in deionized water to prepare 1mol / L A solution; prepare B solution, weigh certain A certain amount of precipitating agent and complexing agent are dissolved in deionized water, wherein the precipitating agent is potassium carbonate, the concentration of potassium carbonate solution is 1mol / L, the complexing agent is ammonium carbonate, and the concentration is 0.05mol / L; polyvinylpyrrolidone is dissolved in In deionized water, stir evenly to prepare a 5.0 g / L polyvinylpyrrolidone solution. Co-precipitation is carried out in four stages: stage 1, add A solution, B solution, and polyvinylpyrrolidone solution dropwise into the deionized aqueous solution, control the pH value of the reaction system to 9.0, the stirring rate is 3000 rpm, and the solution temperature is 60°C 1. Reaction for 2 hours; Stage 2, stop dripping polyvinylpyrrolidone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com