A method of manufacturing a copper-aluminum combined 5G antenna radiator

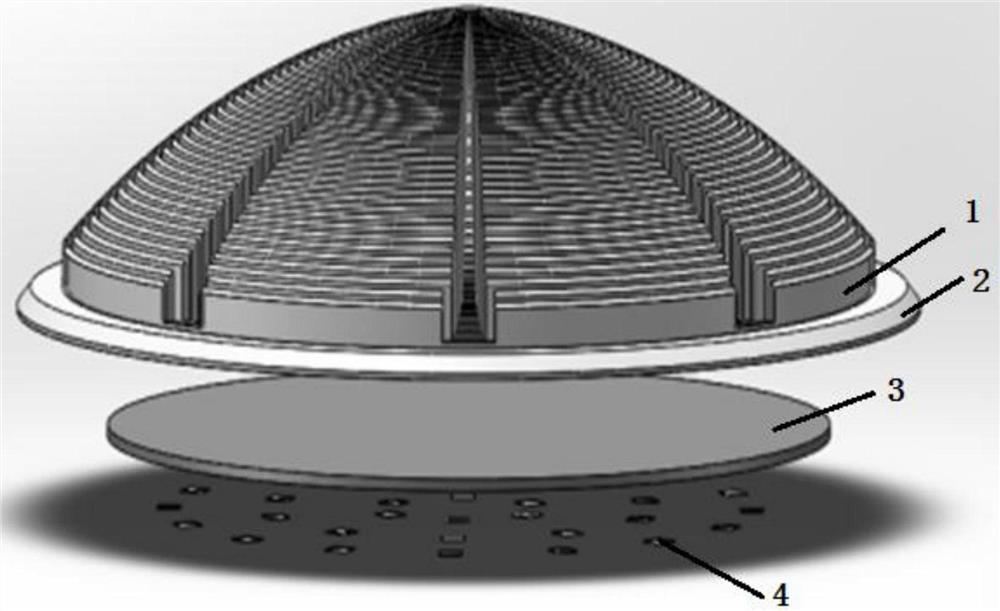

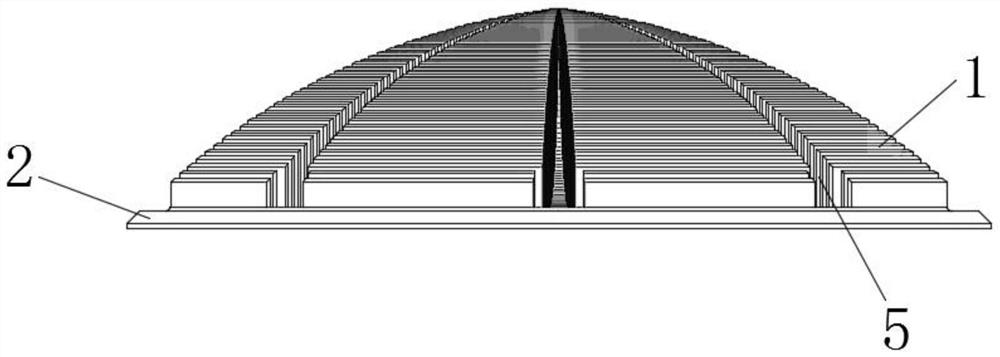

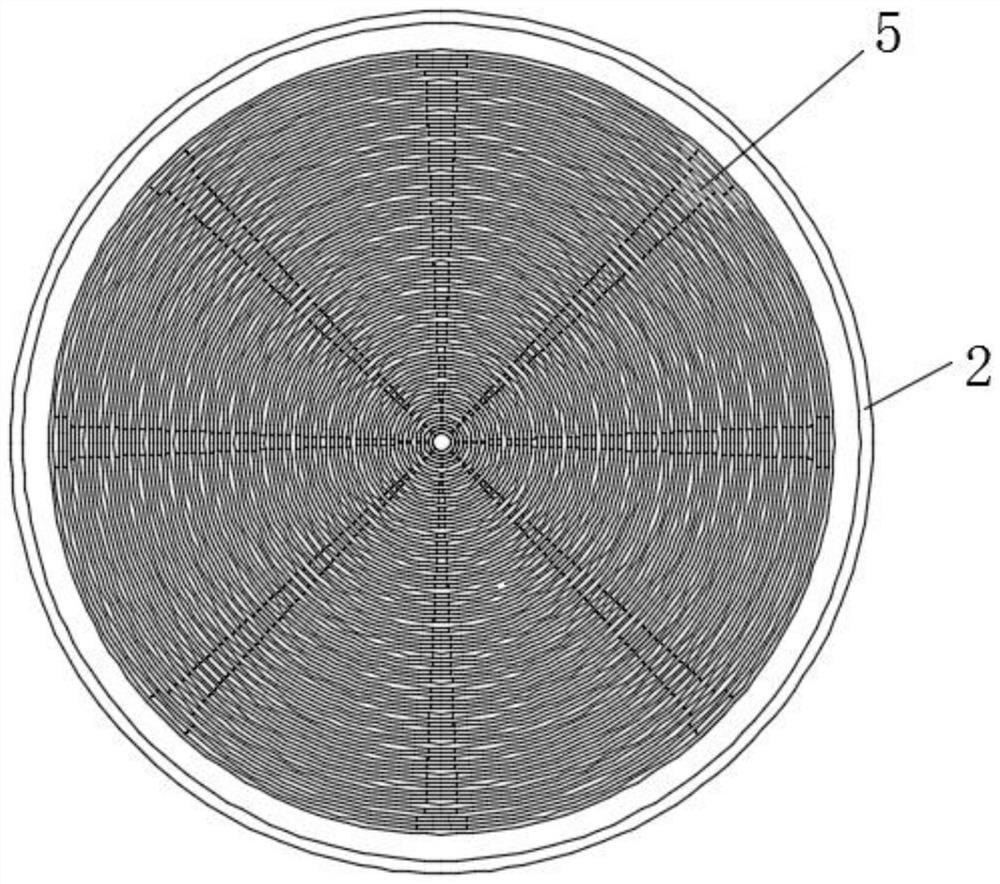

A manufacturing method and radiator technology, which can be applied to antennas, antenna parts, electrical components, etc., can solve the problems of poor heat dissipation performance and reduced heat dissipation efficiency of radiators, and achieve increased surface area, reduced surface temperature, and improved heat accumulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for manufacturing a copper-aluminum combined 5G antenna heat sink, which is made by copper-based aluminum die-casting, comprising the following steps:

[0037] Make the mold:

[0038] Design the mold structure according to the requirements. The die-casting mold adopts H13 mold steel as the mold core, and the mold frame adopts QT600 ductile iron. The mold is heated, and the lubricating liquid is evenly sprayed in the mold, and the pressure casting machine with the casting mold installed is used for die-casting;

[0039] The die-casting mold adopts XR-D coating, the thickness of the coating is 2 μm, the oxidation resistance temperature of the coating is 1300 ℃, the hardness of the coating is HV0.05:4500, and the color is gray-black.

[0040] The core processing method is:

[0041] 1) Modulation, 2) Rough machining, 3) Three tempering treatments, 4) Forming fine electrical machining, 5) Stress relief treatment, 6) Oxidation treatment.

[0042] The mold is to mak...

Embodiment 2

[0054] A method for manufacturing a copper-aluminum combined 5G antenna heat sink, which is made by copper-based aluminum die-casting, comprising the following steps:

[0055] Make the mold:

[0056] Design the mold structure according to the requirements. The die-casting mold adopts H13 mold steel as the mold core, and the mold frame adopts QT600 ductile iron. The mold is heated, and the lubricating liquid is evenly sprayed in the mold, and the pressure casting machine with the casting mold installed is used for die-casting;

[0057] The die-casting mold adopts XR-D coating, the thickness of the coating is 3 μm, the oxidation resistance temperature of the coating is 1400 ℃, the hardness of the coating is HV0.05:4500, and the color is gray-black.

[0058] The core processing method is:

[0059] 1) Modulation, 2) Rough machining, 3) Three tempering treatments, 4) Forming fine electrical machining, 5) Stress relief treatment, 6) Oxidation treatment.

[0060] The mold is to mak...

Embodiment 3

[0072] A method for manufacturing a copper-aluminum combined 5G antenna heat sink, which is made by copper-based aluminum die-casting, comprising the following steps:

[0073] Make the mold:

[0074] Design the mold structure according to the requirements. The die-casting mold adopts H13 mold steel as the mold core, and the mold frame adopts QT600 ductile iron. The mold is heated, and the lubricating liquid is evenly sprayed in the mold, and the pressure casting machine with the casting mold installed is used for die-casting;

[0075] The die-casting mold adopts XR-D coating, the thickness of the coating is 5 μm, the oxidation resistance temperature of the coating is 1500 °C, the hardness of the coating is HV0.05:4500, and the color is gray-black.

[0076] The core processing method is:

[0077] 1) Modulation, 2) Rough machining, 3) Three tempering treatments, 4) Forming fine electrical machining, 5) Stress relief treatment, 6) Oxidation treatment.

[0078] The mold is to ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com