High-temperature steaming resistant composite packaging bag and preparation method thereof

A composite packaging bag and high temperature resistant technology, which is applied in the field of packaging film, can solve the problems of high cost, unfavorable aluminum plating, large investment in coating equipment, etc., and achieve the effects of avoiding various restrictions, reducing production processes and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

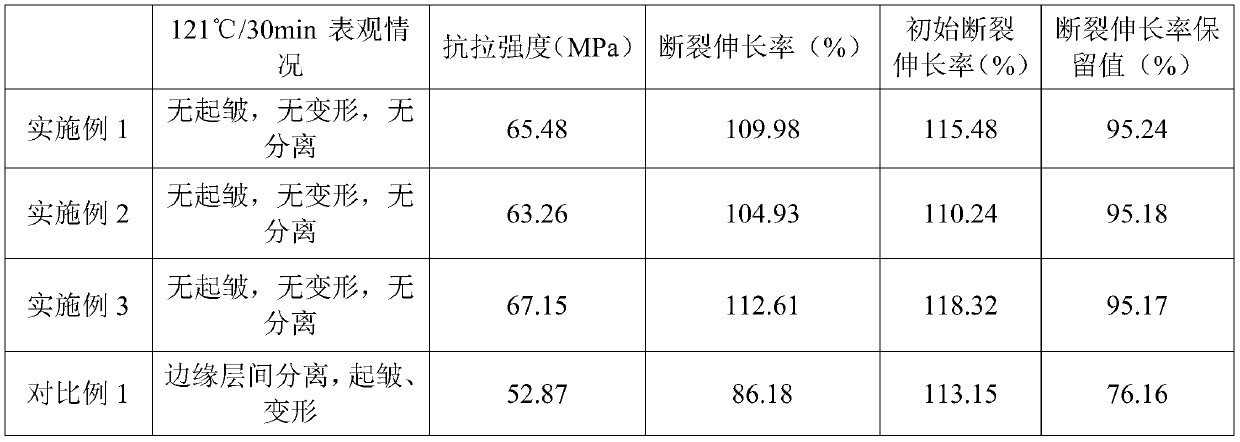

Examples

preparation example Construction

[0025] The present invention also provides a preparation method of a high-temperature cooking-resistant composite packaging bag, the preparation method comprising the following steps:

[0026] The polyester resin layer of the base film layer and the raw materials used for the surface layer are weighed according to the formula, and after being dried and mixed by a mixing device, they are melted and mixed by a twin-screw extruder, and then pressurized by a melt pump to the die for co-extrusion Casting on a large cold drum to cool the cast sheet, fully preheating the obtained cast sheet, stretching longitudinally and transversely respectively, heat setting at 225-240°C, cooling at 60-70°C to obtain the base film layer;

[0027] The heat-sealing layer is compounded on the base film layer through an adhesive, and the composite packaging bag is obtained after being cured and shaped.

Embodiment 1

[0030] A composite packaging bag, comprising a base film layer and a heat-sealing layer compounded on one side of the base film layer through an adhesive; wherein, the base film layer is a three-layer co-extrusion structure, including a polyester resin layer and a surface layers disposed on both sides of the polyester resin layer;

[0031] Described polyester resin layer is PET chips (intrinsic viscosity 0.68dL / g);

[0032] The surface layer includes the following raw materials in parts by weight: 100 parts by weight of PET chips (intrinsic viscosity 0.68dL / g), 35 parts by weight of MAH-g-PE (grafting rate 1.5%), hydrolysis stabilizer epoxy fatty acid alkyl ester 8 parts by weight, polyaryloxyphosphazene fiber ([NP(OC 6 h 4 ) 2 ] n, diameter is 0.3μm, length is 1.2μm) 25 parts by weight, inorganic particle silica (particle size is 0.3 μm) 10 parts by weight, chain extender polycarbodiimide 3 parts by weight, nucleating agent MIllad3988 3 parts by weight , Dispersant polye...

Embodiment 2

[0037] The structure and preparation method of the composite packaging bag in this embodiment are basically the same as in Example 1, the difference is that

[0038] The surface layer includes the following raw materials in parts by weight: 100 parts by weight of PET chip (intrinsic viscosity 0.68dL / g), 25 parts by weight of MAH-g-PE (grafting rate 1.5%), hydrolysis stabilizer epoxy fatty acid alkyl ester 3 parts by weight, polyaryloxyphosphazene fiber ([NP(OC 6 h 4 ) 2 ] n , diameter is 0.3μm, length is 1.2μm) 15 parts by weight, inorganic particle silica (particle size is 0.3 μm) 5 parts by weight, chain extender polycarbodiimide 2 parts by weight, nucleating agent MIllad3988 2 parts by weight , Dispersant polyethylene glycol-20000 2 parts by weight.

[0039] The rest remain unchanged, and the composite packaging bag is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com