Preparation method of 4-(4-phenylbutoxy) benzoic acid

A technology of phenylbutoxy and benzoic acid, applied in the field of preparation of 4-benzoic acid, can solve problems such as being unsuitable for large-scale industrial production, expensive phenylbutanol, complicated process, etc., and achieves short synthetic route and novel route. , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

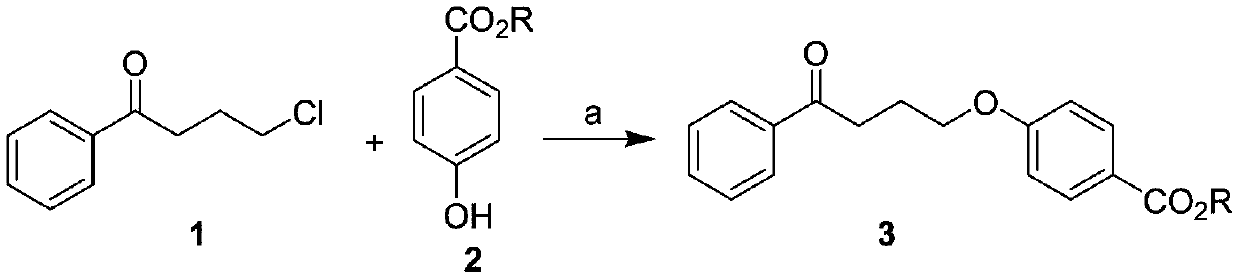

[0038] This example provides a preparation method of 4-(4-phenylbutoxy)benzoic acid, which is specifically carried out according to the following steps, and the compound γ-chlorobutyrophenone is prepared according to the literature method.

[0039] 1. Synthesis of compound 3a: methyl 4-(4-oxo-4-phenylbutoxy)benzoate

[0040] Weigh 9.1 grams of γ-chlorobutanone and 8.4 grams of methyl p-hydroxybenzoate, dissolve them in 100 milliliters of DMF, add 27.6 grams of potassium carbonate, stir, heat up, stir at 100°C for 5 hours, cool down, filter, and decompress the filtrate Concentrate, dissolve in dichloromethane, wash with 1N sodium hydroxide, separate the organic phase, dry over anhydrous sodium sulfate, filter and concentrate to obtain a white solid that is directly used in the next reaction.

[0041] Reaction formula:

[0042]

[0043] 2. Synthesis of compound 3b: benzyl 4-(4-oxo-4-phenylbutoxy)benzoate

[0044] According to the method in the first step, benzyl p-hydroxybe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com