Extraction method of mixed long-chain dicarboxylic acid and mixed long-chain dicarboxylic acid

A long-chain dibasic acid and extraction method technology, which is applied in the field of extraction of mixed long-chain dibasic acids, can solve the problems of ineffective removal of pigments and impurities, low yield of dibasic acid loss, complicated solvent recovery, etc., and achieve quality Good, cost saving, light color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

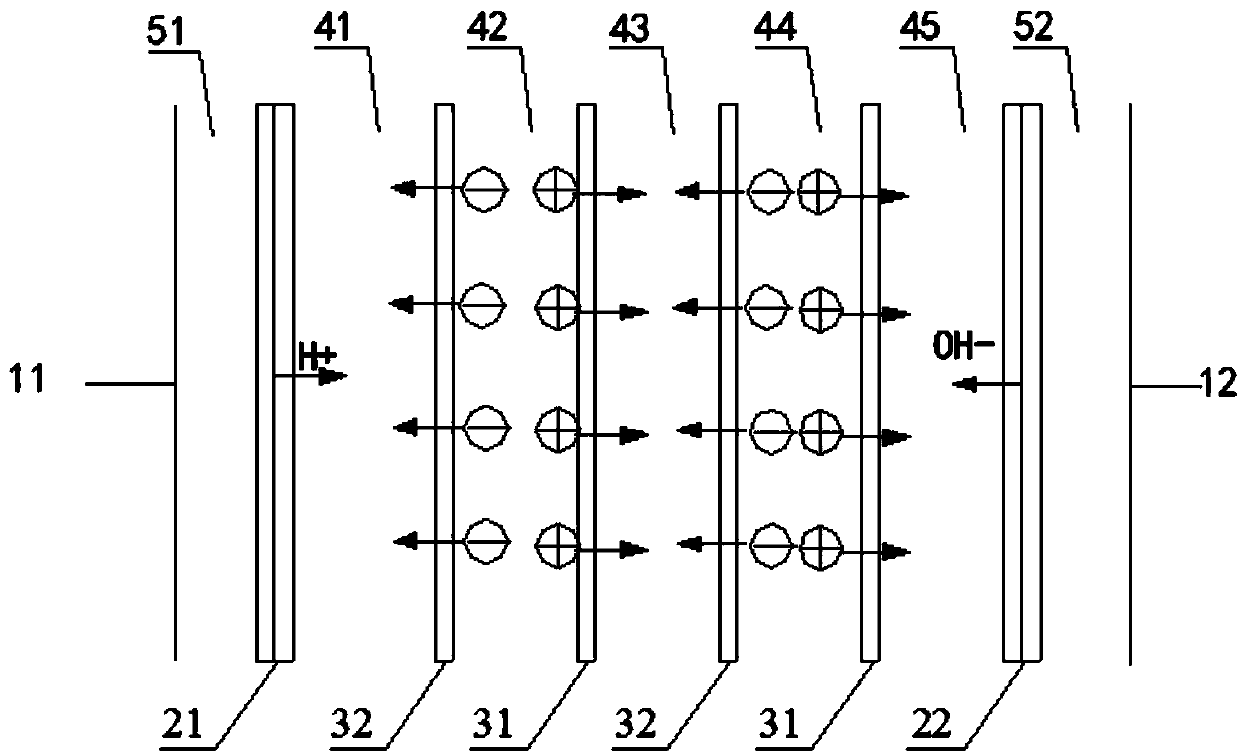

[0084] Electrodialysis unit, comprising: anode 11, cathode 12, bipolar membrane 21, bipolar membrane 22, positive membrane 31, negative membrane 32, pole chamber 51, pole chamber 52, positive membrane 31 and negative membrane 32 are located on bipolar membrane 21 , bipolar membranes 22 and alternately arranged to form concentration chambers and desalination chambers, the concentration chambers and desalination chambers are alternately arranged, followed by concentration chambers 41, desalination chambers 42, concentration chambers 43, desalination chambers 44, and concentration chambers 45. In this embodiment, there is no limit to the number of electrodialysis units in the electrodialysis device.

Embodiment 2

[0086] A method for extracting mixed long-chain dibasic acids, comprising the following steps:

[0087] (1) Convert DC 12 (i.e. dodecanedioic acid, the structural formula is HOOC(CH 2 ) 10 COOH) fermented liquid extracts and refines DC 12 Add the mixture containing long-chain dibasic acid discharged in the process into water, adjust the pH value with aqueous sodium hydroxide solution, stir to dissolve the mixture containing long-chain dibasic acid, the pH value at the end of the dissolution is 10, and pass through the ceramic membrane at 80°C , obtain the mixed long-chain dibasic acid salt solution to be refined (long-chain dibasic acid radical content is 5.8wt%, wherein the content of dodecanoic dibasic acid radical is 4.13wt%, other is DC 10 -DC 16 of dibasic acid radicals).

[0088] (2) make the mixed long-chain dibasic acid salt solution to be refined that step (1) obtains, carry out electrodialysis treatment through the electrodialysis unit that 50 electrodialysis un...

Embodiment 3

[0094] It is basically the same as Embodiment 2, except that in Embodiment 3, the reaction is terminated when the conductivity of the solution in the desalination chamber 44 is below 300 μS / cm.

[0095] The long-chain dibasic acid root yield in the purified mixed long-chain dibasic acid salt solution is 99.1%, and the decolorization rate of the solution is 81.5%. The color of the mixed long-chain dibasic acid product in Example 3 is light yellow.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com