Application of palladium source catalyst in alkyne polymerization

A palladium catalyst and catalyst technology, applied in the field of alkyne polymerization, to achieve the effect of reducing polymerization cost, not easy to be poisoned, and narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1) Add 2 mmol of disubstituted alkyne monomer to an eggplant-shaped bottle, add 3 mL of 1,1,2,2-tetrachloroethane solution, stir with a magnetic stirrer until dissolved, add 0.02 mmol to dissolve in 1,1 , 2,2-tetrachloroethane on palladium carbon, stirred and reacted in an oil bath at 60°C for 2h;

[0051] (2) After the reaction is over, take the eggplant bottle out of the oil bath, cool to room temperature, drop the resulting reaction solution dropwise into the petroleum ether solution for sedimentation, terminate the reaction, precipitate solid matter, filter it with petroleum ether Wash three times, vacuum-dry the resulting solid at 40°C to constant weight to obtain a polymer product, weigh the polymer product and obtain a yield of 78% from the above activity formula, and an activity of 5.9 kg·mol Pd -1 h -1 .

[0052] The polymer product prepared in this embodiment is tested as follows:

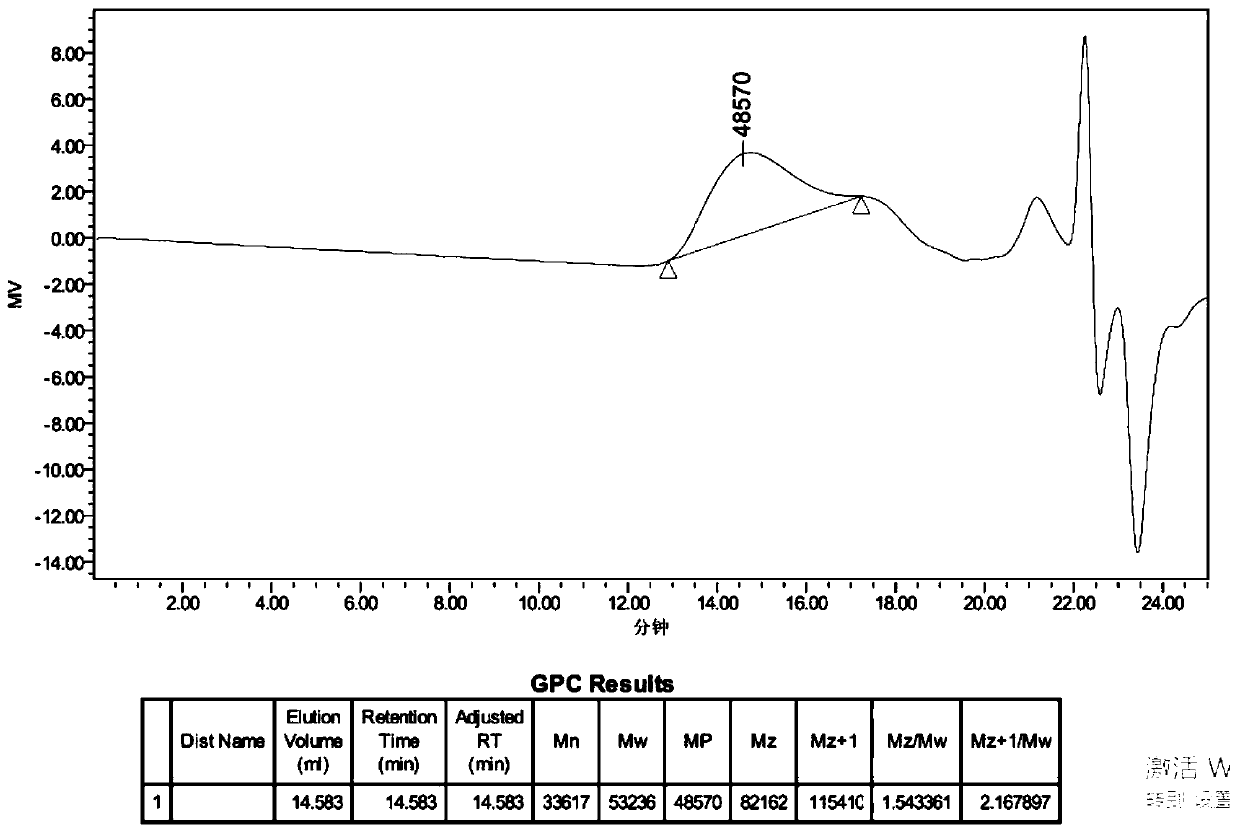

[0053] (1) GPC detection

[0054] The GPC detection result of the polymer...

Embodiment 2

[0056] (1) catalyzer changes palladium acetate into, all the other are with embodiment 1 step (1);

[0057] (2) With embodiment 1 step (2).

[0058] The polymer product prepared in this embodiment is tested as follows:

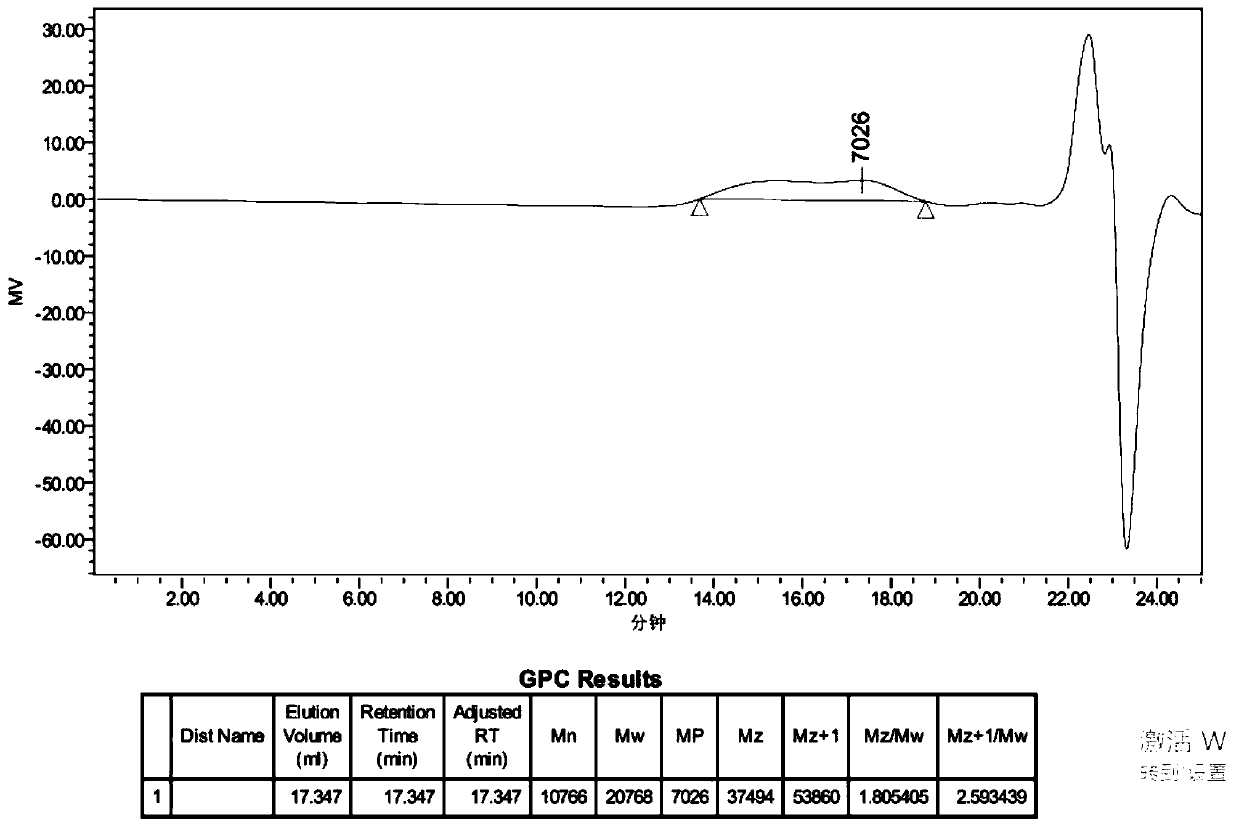

[0059] (1) GPC detection

[0060] The GPC detection result of the polymerization product prepared in this embodiment is shown in figure 2 ,Depend on figure 2 Integral at middle retention time 17.3min shows that the number average molecular weight M of the polymerization product n =21000, molecular weight distribution M w / M n = 1.93.

Embodiment 3

[0062] (1) catalyzer changes palladium chloride into, all the other are with embodiment 1 step (1);

[0063] (2) With embodiment 1 step (2).

[0064] The polymer product prepared in this embodiment is tested as follows:

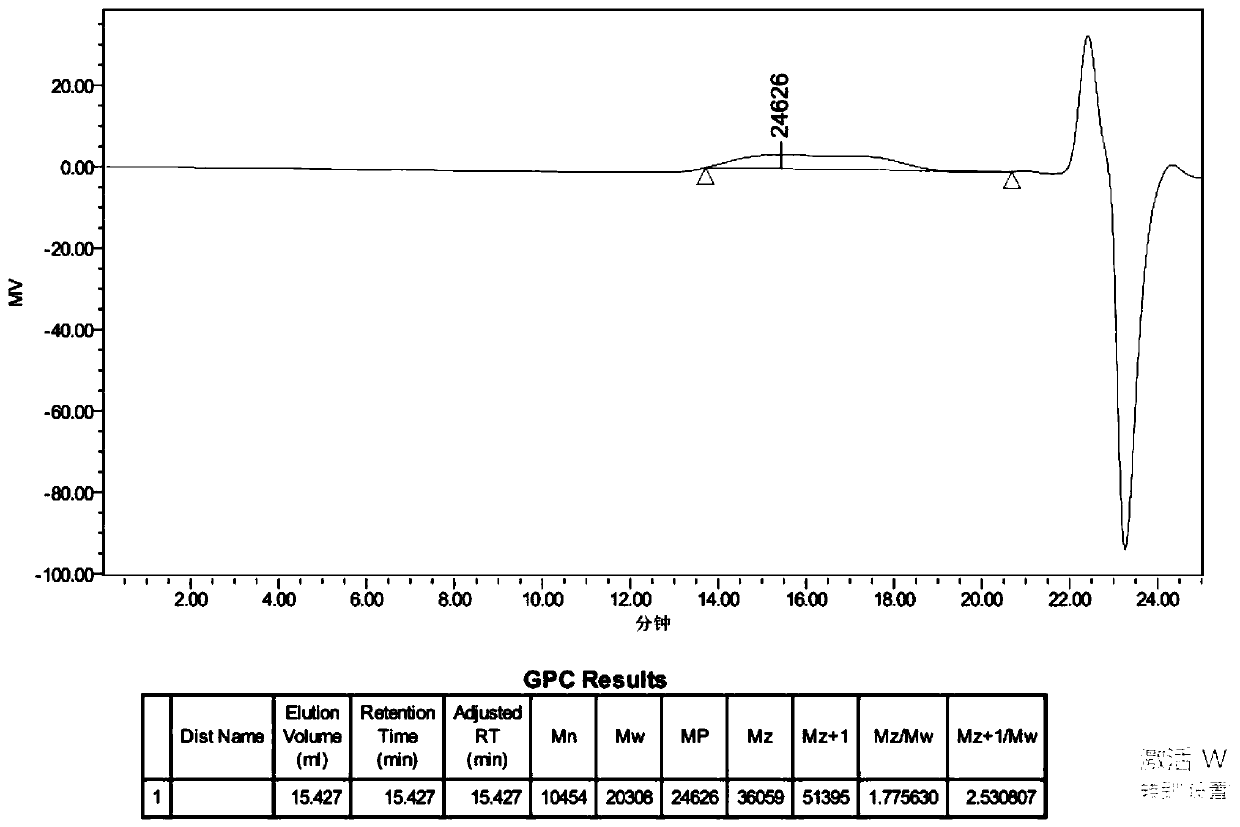

[0065] (1) GPC detection

[0066] The GPC detection result of the polymerization product prepared in this embodiment is shown in image 3 ,Depend on image 3 Integral at middle retention time 15.4min shows that the number average molecular weight M of the polymerization product n =20000, molecular weight distribution M w / M n = 1.94.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com