Odorless polyurethane waterproof coating and preparation method thereof

A polyurethane waterproofing and coating technology, used in polyurea/polyurethane coatings, coatings, devices for coating liquids on surfaces, etc. Effects of adsorption, excellent mechanical properties and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Odor-free polyurethane waterproof coating is a constant temperature one-component polyurethane product.

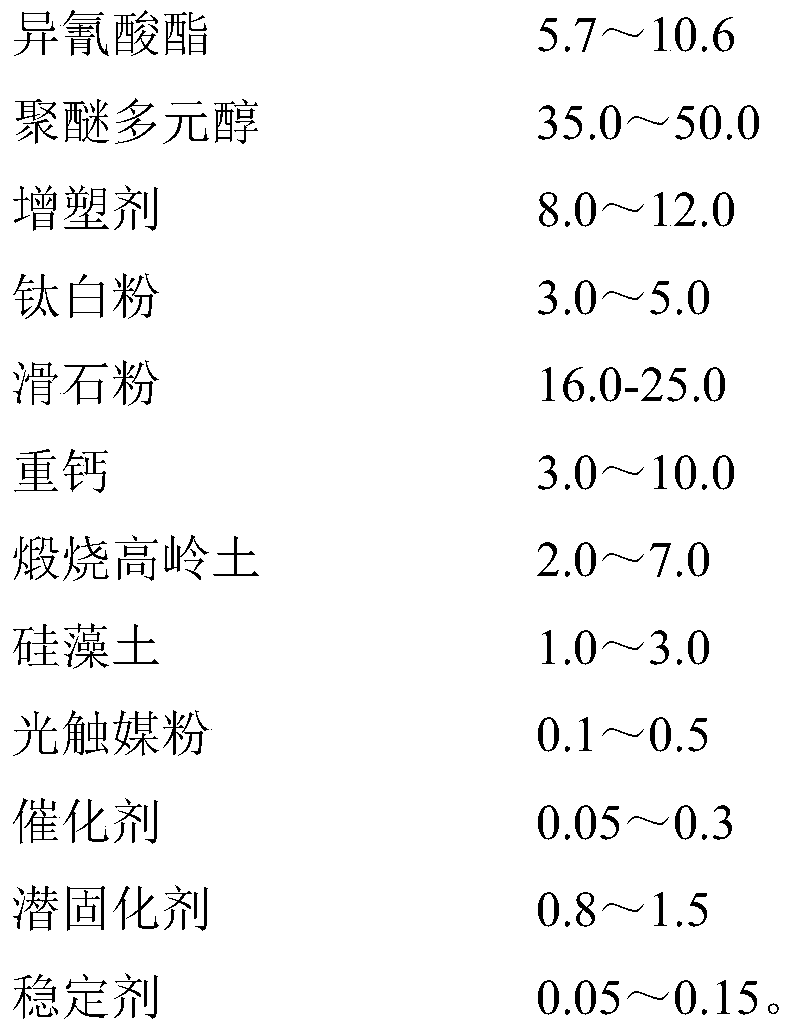

[0045]

[0046] The preparation method is as follows:

[0047] Add polyether polyols, plasticizers, and antioxidants into the reactor, set the stirring speed to 200 rpm, and heat the reactor. When the temperature of the reactor rises to 70°C, add titanium dioxide and talcum powder in sequence , heavy calcium, calcined kaolin, diatomaceous earth and photocatalyst, when the temperature of the reactor rises to between 115°C, turn on the vacuum pump connected to the reactor to evacuate the reactor, and make the reactor at a vacuum degree of -0.095 Continue vacuuming between Mpa for 5 hours, then turn off the vacuum pump;

[0048] After the dehydration is completed, close the vacuum valve and set the temperature to 50°C. After the temperature is cooled to 50°C, add TDI to keep the temperature for 1 hour;

[0049] Then the temperature was raised to 60°C for 1 hour at...

Embodiment 2

[0058] Odor-free polyurethane waterproof coating is a constant temperature one-component polyurethane product

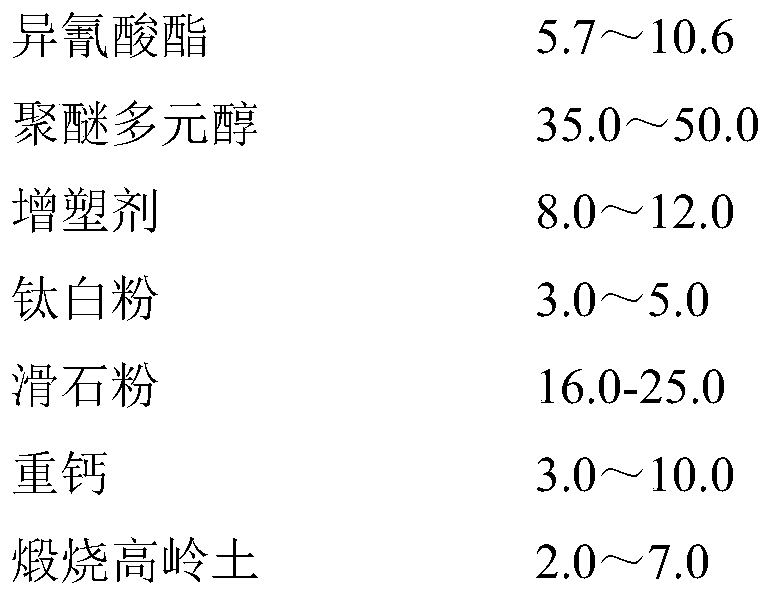

[0059] The prescription components are:

[0060]

[0061] Preparation:

[0062] Add polyether polyols and plasticizers into the reactor, set the stirring speed to 600 rpm, and heat the reactor. When the temperature of the reactor rises to 80°C, add titanium dioxide, talcum powder, heavy calcium, Calcined kaolin, diatomaceous earth and photocatalyst, when the temperature of the reactor rose to 125°C, turn on the vacuum pump connected to the reactor to evacuate the reactor, and keep the reactor vacuum at -0.1Mpa for 2 hours , then turn off the vacuum pump;

[0063] After the dehydration is completed, close the vacuum valve and set the temperature to 45°C. After the temperature cools down to 45°C, add TDI to keep the temperature for 1-2 hours;

[0064] Then the temperature was raised to 55° C. for 2 hours at a constant temperature;

[0065] Heat up to 65°C for 2 ...

Embodiment 3

[0073] Odor-free polyurethane waterproof coating is a constant temperature one-component polyurethane product

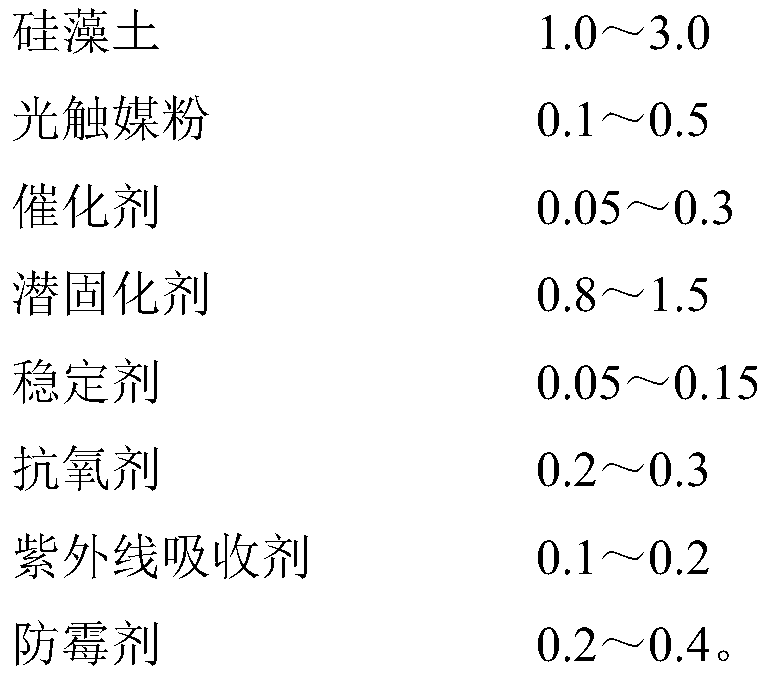

[0074] The prescription components are:

[0075]

[0076] Production Process:

[0077] Add polyether polyols and plasticizers into the reactor, set the stirring speed to 300 rpm, and heat the reactor. When the temperature of the reactor rises to 72°C, add titanium dioxide, talcum powder, heavy calcium, Calcining kaolin, diatomaceous earth and photocatalyst, when the temperature of the reactor rises to 118°C, turn on the vacuum pump connected to the reactor to evacuate the reactor, and keep the reactor at a vacuum degree of -0.096Mpa Vacuumize for 2.5 hours, then turn off the vacuum pump;

[0078] After the dehydration is completed, close the vacuum valve and set the temperature to 55°C, and add TDI to keep the temperature for 1 hour after the temperature is cooled to 55°C;

[0079] Then the temperature was raised to 55° C. for 1 hour at a constant temperature; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com