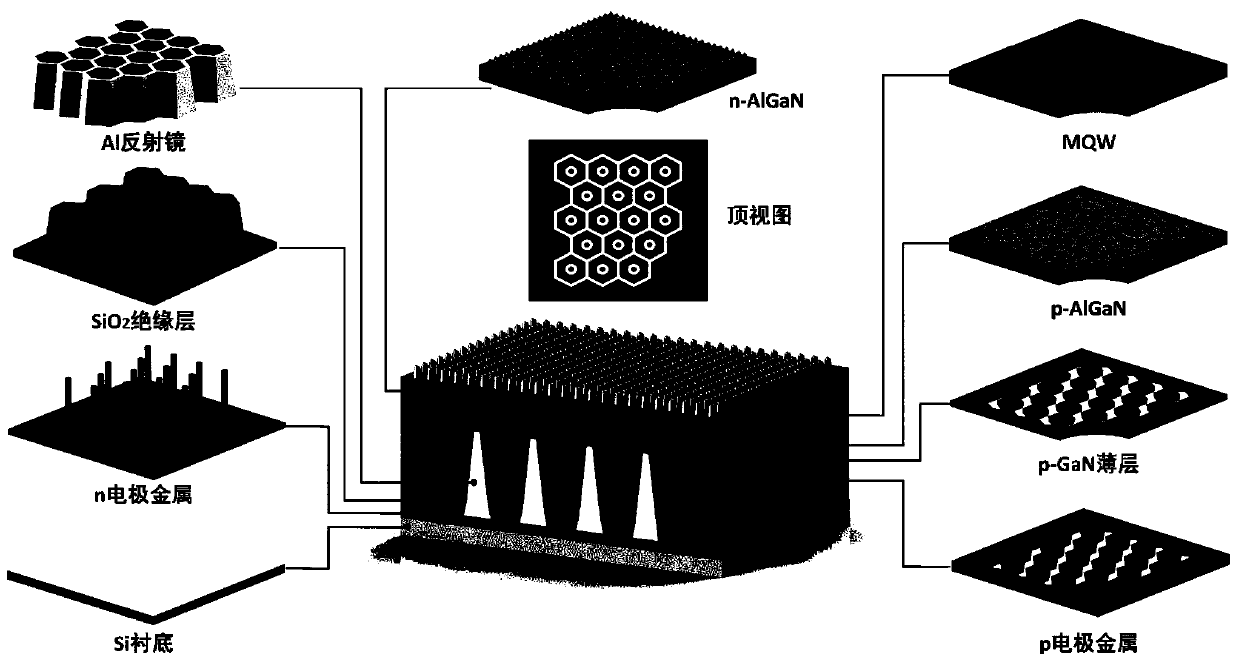

Manufacturing method of deep ultraviolet LED chip with vertical structure

A technology of LED chips and manufacturing methods, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of low optical output power and external quantum efficiency, long propagation path, and affecting TM polarized light propagation, and reduce the source area. Loss, good ohmic contact performance, effect of improving light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

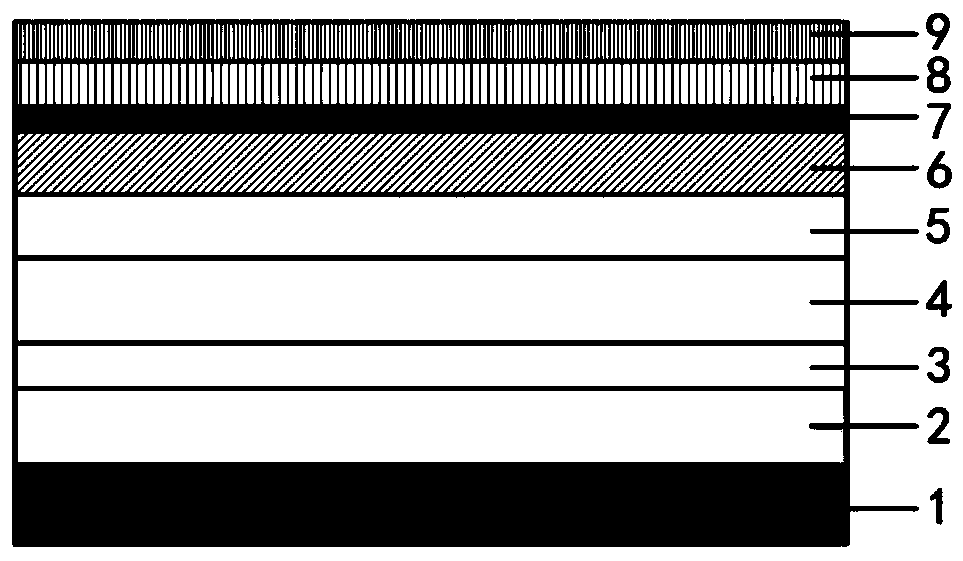

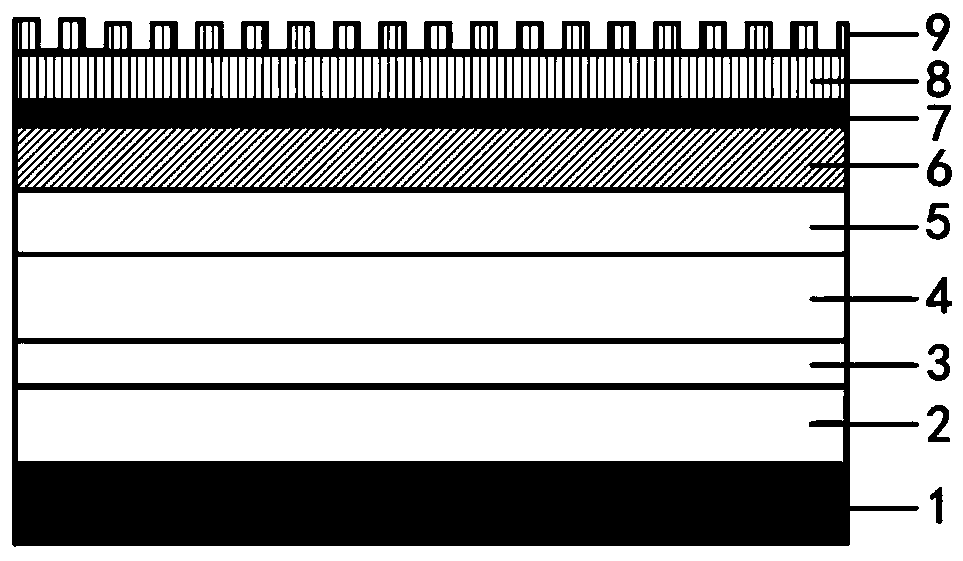

[0064] A method for manufacturing a vertical structure deep ultraviolet LED chip is provided, and the specific steps are as follows:

[0065] (1) Put the cleaned sapphire substrate 1 into the MOCVD epitaxial growth device 1 at a temperature of 650°C, and grow a 35nm AlN nucleation layer 2 .

[0066] (2) At a temperature of 1100°C, continue to grow undoped Al 0.45 Ga 0.55 N buffer layer 3 with a thickness of 175-225nm, keep the temperature constant, and grow a layer of Si-doped n-Al 0.7 Ga 0.3 N layer 4 and n-Al 0.6 Ga 0.4 N layer 5 with a thickness of 2.5 μm and 0.5 μm and a doping concentration of 1.6×10 19 cm -3 .

[0067] (3) At a temperature of 760°C, grow Al for 5 cycles 0.4 Ga 0.6 N / Al 0.64 Ga 0.36 The quantum well is used as the active layer 6, and the thickness of the quantum well layer is about 2.7nm.

[0068] (4) Deposit SiO at low temperature 2 or Si 3 N 4 Material electron blocking layer 7 (EBL), and then use the electron beam evaporation method to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com