SCR denitration coal-fired power plant liquid slagging boiler waste gas treatment system and method

A technology of liquid slag discharge and boiler exhaust gas, which is applied in the direction of chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of hindering the downstream flow of slag liquid, polluting the production site, and fluctuating slag hopper airflow, so as to avoid clogging of slag liquid, The effect of preventing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

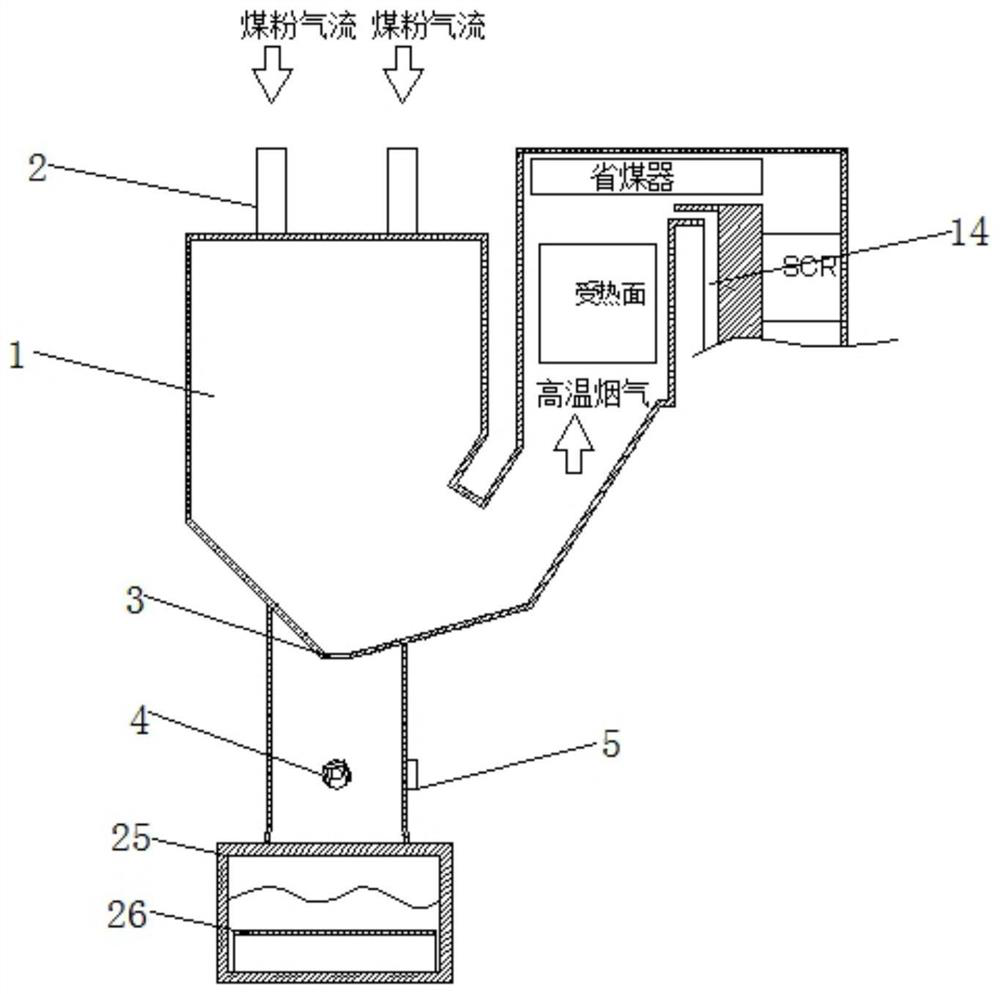

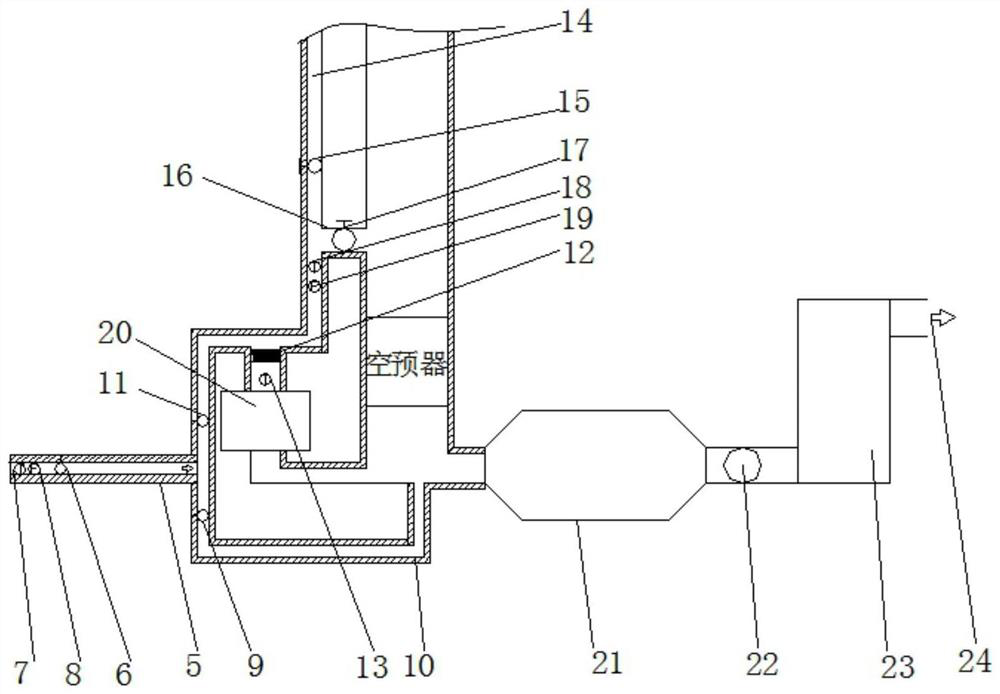

[0023] refer to Figure 1-2 , an SCR denitrification coal-fired power plant liquid slagging boiler waste gas treatment system, including a boiler slag system, a waste flue gas pollutant purification system, a waste gas SCR denitrification system, and a waste slag treatment system. The waste slag treatment system includes a slag pool 25 and a slag removal machine 26. The waste gas pollutant purification system includes the waste gas pipe interface 4, the waste gas pipe 5, the waste gas pipe regulating door 6, the waste gas temperature measuring point 7 and the waste gas flow measuring point 8, the waste gas pipe connection 4 is connected with the waste gas pipe 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com