Three-dimensional graphene/COFs composite material as well as preparation method and application thereof

A composite material, graphene technology, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve problems that violate the vision of green environmental protection and economic effects, consume energy, and improve rapid separation characteristics and stability, improve mechanical strength, enhance the effect of rapid separation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

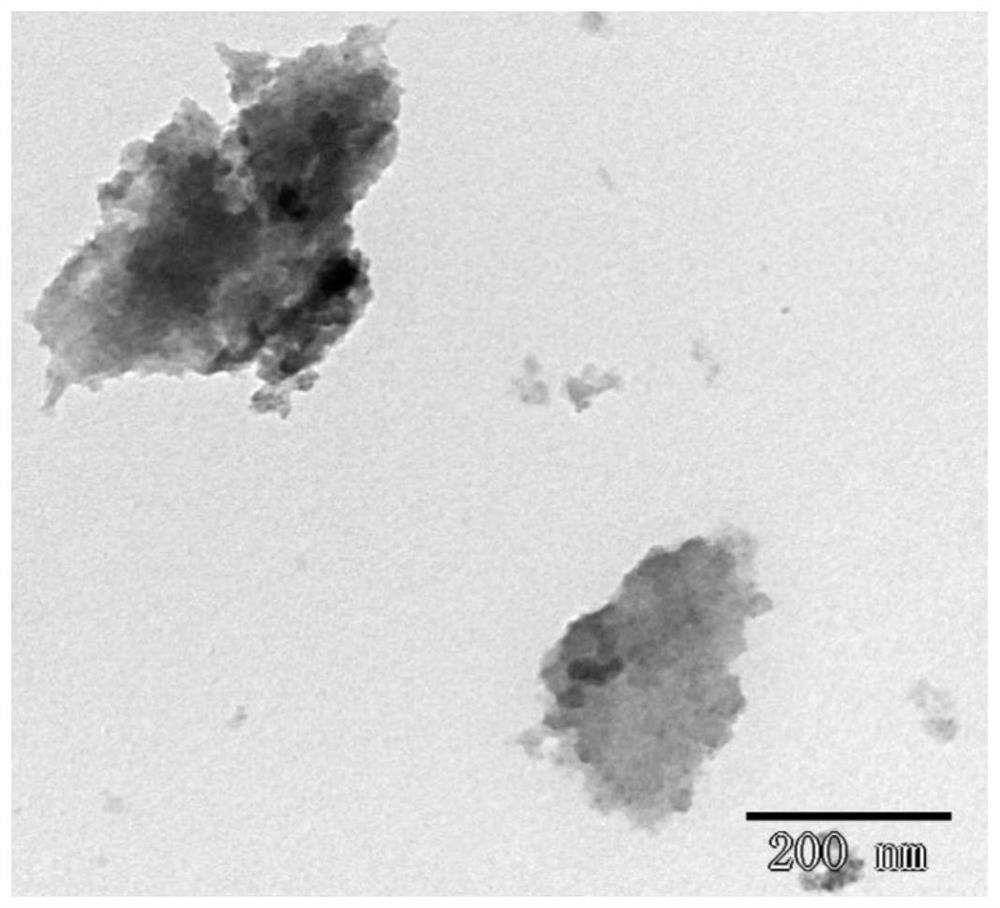

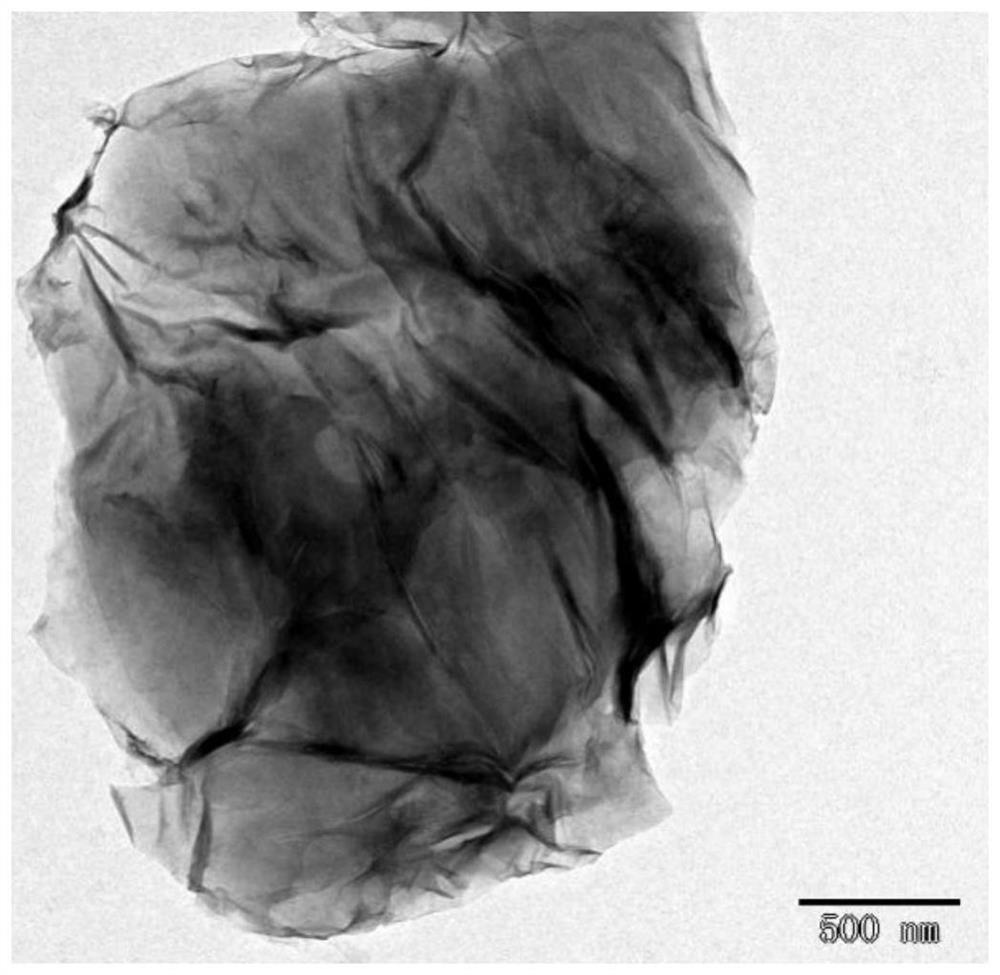

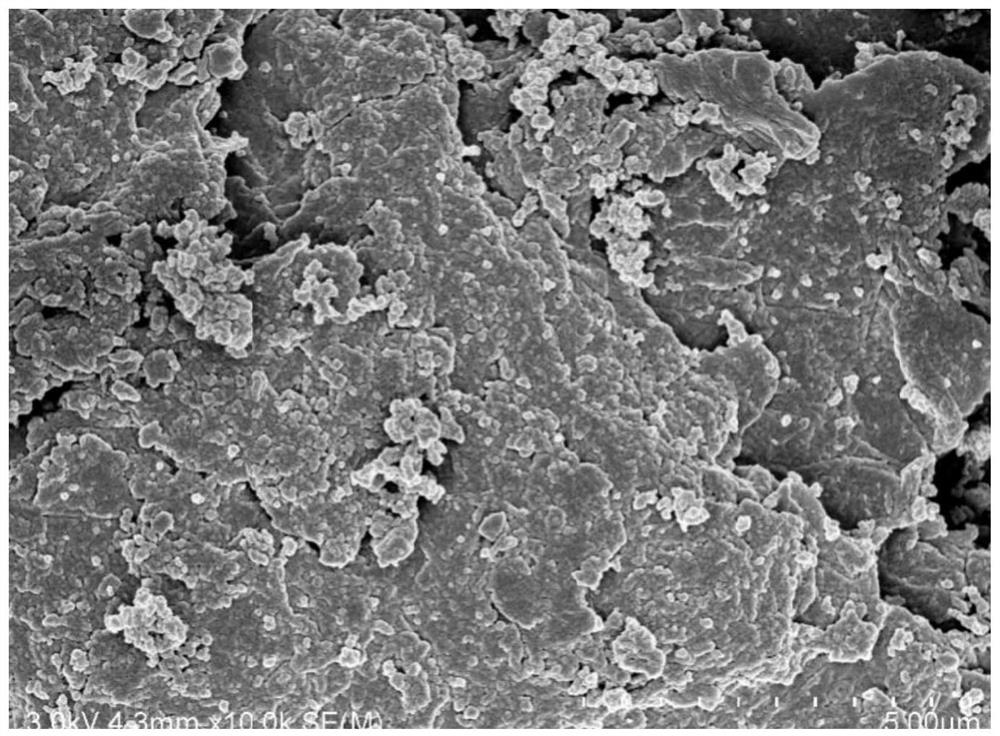

[0036] The preparation method of the three-dimensional graphene hydrogel of the present invention comprises: mixing and dissolving at least one of ascorbic acid and hydrazine hydrate with graphene oxide, and stirring with magnetic force until a black solid product is generated. Specifically, dissolve graphene oxide and ascorbic acid in ultrapure water, and ultrasonicate for about 5 minutes to completely dissolve the solid particles; then mix and disperse the above mixed solution with a certain volume of high-purity water, and heat and continue stirring for 1 hour under magnetic stirring There is enough until a black solid product is generated; then centrifuged, washed with absolute ethanol and pure water for about three times, and freeze-dried for about 48 hours.

[0037] In a preferred embodiment, graphene oxide and ascorbic acid are used for mixing and dissolving; wherein, the volume ratio of the volume of ultrapure water, the quality of graphene oxide, the quality of ascorbi...

Embodiment 1

[0044] Preparation of three-dimensional graphene hydrogel: First, graphene oxide and ascorbic acid were dissolved in 10 mL of ultrapure water, and the solid particles were completely dissolved by ultrasonication for 5 min. Secondly, the above mixed solution and a certain volume of high-purity water were dispersed into a 250mL three-necked flask, and heated and stirred continuously for 1h under magnetic stirring until a black solid product was formed. Finally, it was separated by high-speed centrifugation, washed three times alternately with absolute ethanol and pure water, and dried in a freeze dryer for 48 hours.

[0045] Wherein, graphene oxide: ascorbic acid: high-purity water: reaction temperature: centrifugal revolution number is:

[0046] 0.2g: 1.0g: 110mL: 90°C: 12000r / min.

[0047] Self-assembly of 3D graphene / COFs composites: Suspend the 3D graphene hydrogel in 20mL DMSO and sonicate for 5min, then add DMSO solution containing trimesaldehyde and benzidine, after soni...

Embodiment 2

[0051] Preparation of three-dimensional graphene hydrogel: First, graphene oxide and ascorbic acid were dissolved in 9 mL of ultrapure water, and the solid particles were completely dissolved by ultrasonication for 6 min. Secondly, the above-mentioned mixed solution and a certain volume of high-purity water were dispersed into a 250 mL three-necked flask, and heated and stirred continuously for 1.2 h under magnetic stirring until a black solid product was formed. Finally, it was separated by high-speed centrifugation, washed four times alternately with absolute ethanol and pure water, and dried in a freeze dryer for 50 hours.

[0052] Wherein, graphene oxide: ascorbic acid: high-purity water: reaction temperature: centrifugal revolution number is:

[0053] 0.1g: 0.4g: 60mL: 65°C: 10000r / min.

[0054] Self-assembly of 3D graphene / COFs composites: Suspend the 3D graphene hydrogel in 18mL DMSO and sonicate for 6min, then add DMSO solution containing trimesaldehyde and benzidine,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com