Alkali-free aluminoborosilicate glass

A technology of borosilicate glass and alkali aluminum, which is applied in glass production, instruments, optics, etc., can solve the problems of poor glass uniformity, large boron volatilization, furnace erosion, etc., and achieve high hardness and high Young's modulus amount, high strain point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

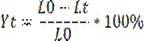

Image

Examples

preparation example Construction

[0036] A kind of preparation method of alkali-free aluminum borosilicate glass, adopts the proportion described in table 1-5, wherein SiO 2 、Al 2 o 3 , B 2 o 3 , MgO, CaO, SrO, ZrO 2 ,P 2 o 5 It means that the composition contains Si-containing compounds, Al-containing compounds, B-containing compounds, Mg-containing compounds, Ca-containing compounds, Sr-containing compounds, Zr-containing compounds, and P-containing compounds, (such as: carbonates containing the aforementioned elements, Nitrates, sulfates, oxides, etc., the content of each component is based on the oxides of each element), according to the different glass preparation processes, the composition contains a clarifying agent, there is no special limitation on the specific selection of the clarifying agent, you can Various choices commonly used in this field; Under heating condition, described SiO 2 、Al 2 o 3 , B 2 o 3 , MgO, CaO, SrO, ZrO 2 ,P 2 o 5 After mixing evenly, carry out high-temperature m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com