Method for recovering acidic DMF in sucralose production

A technology of sucralose and a recovery method, which is applied to the preparation of sugar derivatives, sugar derivatives, and sugar derivatives, etc., can solve the problems of intractable solid salt residue, DMF loss, DMF decomposition, etc. The effect of cost reduction and fewer side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

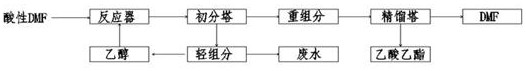

Image

Examples

Embodiment 1

[0020] (1) Add 3000 L of acidic DMF (5wt% acetic acid, 80wt% DMF) into the reactor, add 300 L of ethanol to react, and the reaction temperature is 85°C, so that the pH value of the reaction mixture is 6.0;

[0021] (2) The reaction mixture is input into the rectification tower, and the operating conditions of the rectification tower are: feed amount 0.9m 3 / h, reflux ratio 1:3, kettle temperature 80°C, top temperature 50°C, negative pressure -0.08Mpa; a mixture containing DMF and ethyl acetate was obtained at the bottom of the tower, and a mixture containing ethanol, acetic acid and water was obtained at the top of the tower;

[0022] (3) The bottom mixture is sent to the light removal tower for rectification, and the bottom mixture (ethyl acetate, DMF) is subjected to rectification and separation operation. , the high-purity DMF obtained at the bottom of the rectification tower, and the ethyl acetate obtained by delighting are returned to the sucralose system to reuse the sep...

Embodiment 2

[0025] (1) Add 3,000 L of acidic DMF (12wt% acetic acid, 80wt% DMF) into the reactor, add 500 L of ethanol to react, and the reaction temperature is 85°C, so that the pH of the reaction mixture is 6.3;

[0026] (2) The reaction mixture is input into the rectification tower, and the operating conditions of the rectification tower are: feed amount 1m 3 / h, reflux ratio 1:3, kettle temperature 78°C, top temperature 48°C, negative pressure -0.07Mpa; a mixture containing DMF and ethyl acetate was obtained at the bottom of the tower, and a mixture containing ethanol, acetic acid and water was obtained at the top of the tower;

[0027] (3) The bottom mixture is sent to the light removal tower for rectification, and the bottom mixture (ethyl acetate, DMF) is subjected to rectification and separation operation. , the high-purity DMF obtained at the bottom of the rectification tower, and the ethyl acetate obtained by delighting are returned to the sucralose system to reuse the separated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com