Surfactant for reservoir reconstruction and preparation method thereof

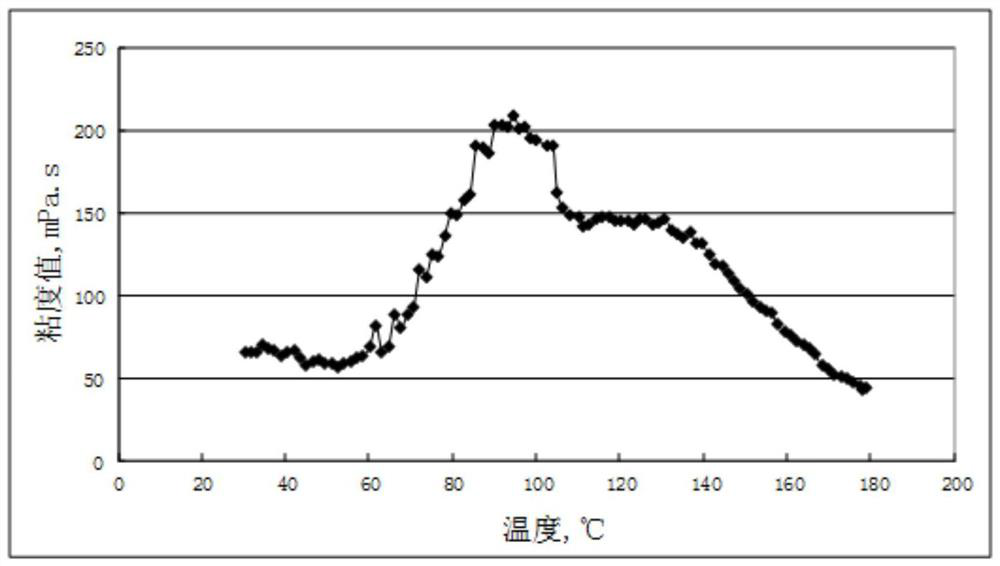

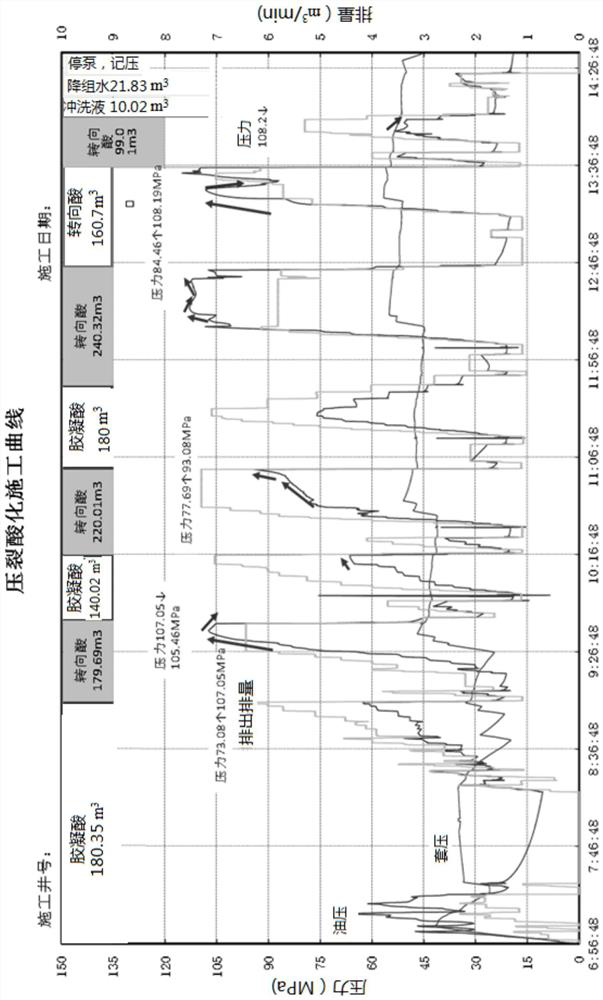

A surfactant, a technology for reservoir reconstruction, which is applied in the preparation of sulfonic acid, chemical instruments and methods, and the composition of drilling holes, etc., can solve the problem of not giving test data of temperature resistance, etc. Temperature resistance, the effect of decontamination of the reservoir

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

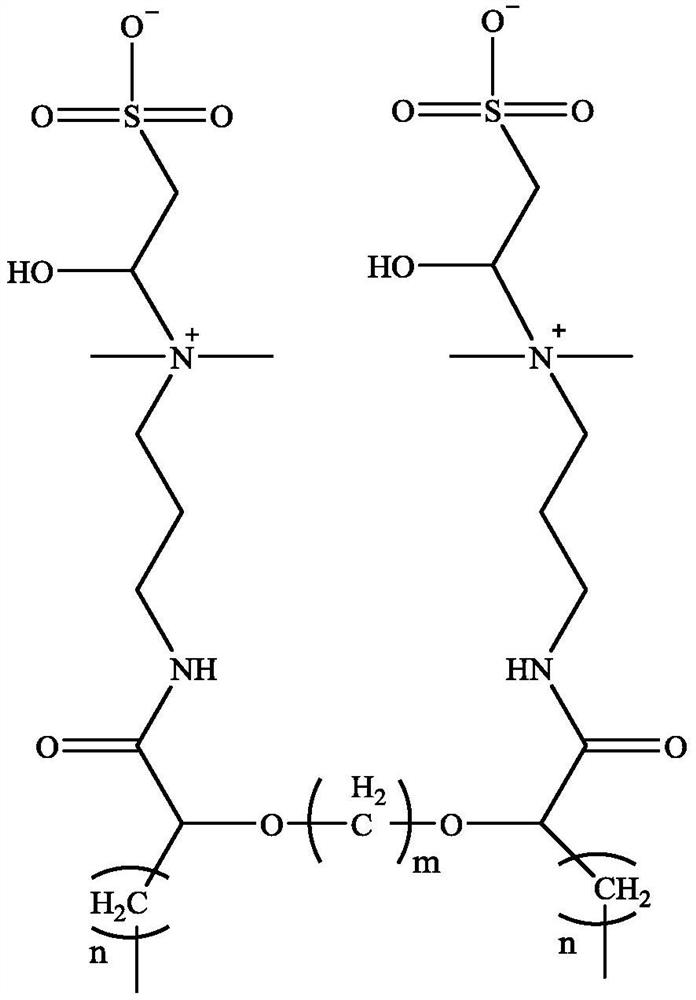

[0048] Add 218.5g of dodecanoyl chloride and 2.54g of elemental iodine into a three-necked flask as a catalyst. After standing for 30 minutes, slowly add 84g of elemental bromine dropwise at a constant speed. The dropping time is controlled at 45-50min, and the temperature is raised to 60°C to start the reaction. After 360 min, the temperature was lowered to 50° C. at a rate of 1° C. / min to obtain intermediate 1a.

[0049] After the intermediate 1a was obtained, 37 g of methanol was added, and cooled to 20° C. at a cooling rate of 1.5° C. / min. The liquid obtained after cooling was washed 4-6 times with saturated aqueous sodium bisulfite solution, and then washed 3-5 times with pure water. The liquid obtained after washing was dried at 95°C for 12 hours, and then filtered to obtain intermediate 2a.

[0050] After obtaining intermediate 2a, anhydrous potassium carbonate 0.8g and acetone 3.4g were mixed in 99.99% N 2 Put it into a three-necked flask under protection, and add 10...

Embodiment 2

[0055] Add 120g of valeryl chloride and 2.54g of elemental iodine into a three-necked flask as a catalyst. After standing for 30 minutes, slowly add 84g of elemental bromine dropwise at a constant speed. The dropping time is controlled at 45-50min. Raise the temperature to 60°C and start the reaction for 360min. , the temperature was lowered to 50°C at a rate of 1°C / min to obtain intermediate 1b.

[0056] After the intermediate 1b was obtained, 37 g of methanol was added and cooled to 20° C. at a cooling rate of 1.5° C. / min. The liquid obtained after cooling was washed 4-6 times with saturated aqueous sodium bisulfite solution, and then washed 3-5 times with pure water. The liquid obtained after washing was dried at 95 °C for 12 hours, and then filtered to obtain intermediate 2b.

[0057] After obtaining intermediate 2b, anhydrous potassium carbonate 0.8g and ethanol 4.1g were mixed in 99.99% N 2 Put it into a three-necked flask under protection, and add 36 g of ethylene gly...

Embodiment 3

[0062] Add 373g of tricosyl chloride and 2.54g of elemental iodine into a three-necked flask as a catalyst. After standing for 30 minutes, slowly add 84g of elemental bromine dropwise at a constant speed. The dropping time is controlled at 45-50min, and the temperature is raised to 60°C to start the reaction. After 360 min, the temperature was lowered to 50° C. at a rate of 1° C. / min to obtain intermediate 1c.

[0063] After the intermediate 1c was obtained, 37 g of methanol was added, and cooled to 20° C. at a cooling rate of 1.5° C. / min. The liquid obtained after cooling was washed 4-6 times with saturated aqueous sodium bisulfite solution, and then washed 3-5 times with pure water. The liquid obtained after washing was dried at 95°C for 12 hours, and then filtered to obtain intermediate 2c.

[0064] After obtaining intermediate 2c, anhydrous sodium carbonate 0.6g and chloroform 7.1g were mixed in 99.99% N 2 It was added into a three-necked flask under protection, and 148 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com