Novel nanometer surgical mask filtering material and manufacturing method thereof

A technology of filter material and manufacturing method, which is applied in the direction of non-woven fabrics, filament/thread forming, textiles and papermaking, etc., can solve the problems of inability to block PM2.5 new coronavirus, poor protection effect, poor comfort, etc., to achieve High filtering effect, comfortable breathing experience, high barrier efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

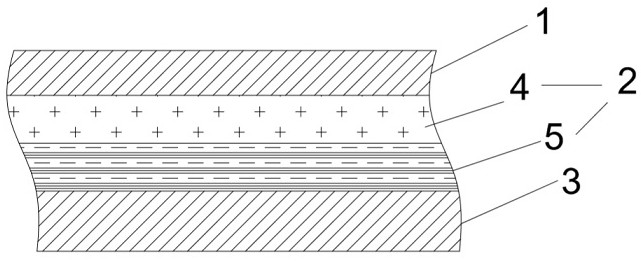

[0021] A novel nano-mask filter material, comprising an outer layer 1, an intermediate layer 2, and an inner layer 3, the outer layer 1 is a water-blocking layer, the intermediate layer 2 is a filter layer, and the inner layer 3 is a hygroscopic layer, It is characterized in that: the filter layer is composed of nano-membrane composite material, and the nano-membrane composite material includes nano-membrane 4 and hot-air cotton 5 . The diameter of described nano film 4 is 100-200 nanometers, and the preparation method of above-mentioned embodiment comprises the following steps:

[0022] S1, spread the hot air cotton 5 on the internally grounded metal plate;

[0023] S2, dissolving the nano-film polymer in formic acid and acetone solvent with a volume ratio of 3:2, and stirring until completely dissolved to obtain a nano-film polymer solution;

[0024] S3, placing the obtained nano-film polymer solution into the syringe pump, connecting the syringe pump and the spinneret thro...

Embodiment 2

[0027] A novel nano-mask filter material, comprising an outer layer 1, an intermediate layer 2, and an inner layer 3, the outer layer 1 is a water-blocking layer, the intermediate layer 2 is a filter layer, and the inner layer 3 is a hygroscopic layer, It is characterized in that: the filter layer is composed of nano-membrane composite material, and the nano-membrane composite material includes nano-membrane 4 and hot-air cotton 5 . The diameter of described nano film 4 is 100-200 nanometers, and the preparation method of above-mentioned embodiment comprises the following steps:

[0028] S1, spread the hot air cotton 5 on the internally grounded metal plate;

[0029] S2, dissolving the nano-film polymer in formic acid and acetone solvent with a volume ratio of 3:2, and stirring until completely dissolved to obtain a nano-film polymer solution;

[0030] S3, placing the obtained nano-film polymer solution into the syringe pump, connecting the syringe pump and the spinneret thro...

Embodiment 3

[0033] A novel nano-mask filter material, comprising an outer layer 1, an intermediate layer 2, and an inner layer 3, the outer layer 1 is a water-blocking layer, the intermediate layer 2 is a filter layer, and the inner layer 3 is a hygroscopic layer, It is characterized in that: the filter layer is composed of nano-membrane composite material, and the nano-membrane composite material includes nano-membrane 4 and hot-air cotton 5 . The diameter of described nano film 4 is 100-200 nanometers, and the preparation method of above-mentioned embodiment comprises the following steps:

[0034] S1, spread the hot air cotton 5 on the internally grounded metal plate;

[0035] S2, dissolving the nano-film polymer in formic acid and acetone solvent with a volume ratio of 3:2, and stirring until completely dissolved to obtain a nano-film polymer solution;

[0036] S3, placing the obtained nano-film polymer solution into the syringe pump, connecting the syringe pump and the spinneret thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com