Porous carbon-loaded monatomic metal nitrogen coordination composite material and preparation method thereof

A composite material, porous carbon technology, applied in the preparation/purification of carbon, nitrogen-metal/silicon/boron binary compounds, nitrogen compounds, etc., can solve the problem of poor stability of single-atom materials, catalytic stability to be improved, The problem of high single-atom surface energy is suitable for large-scale production, easy to mass production, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

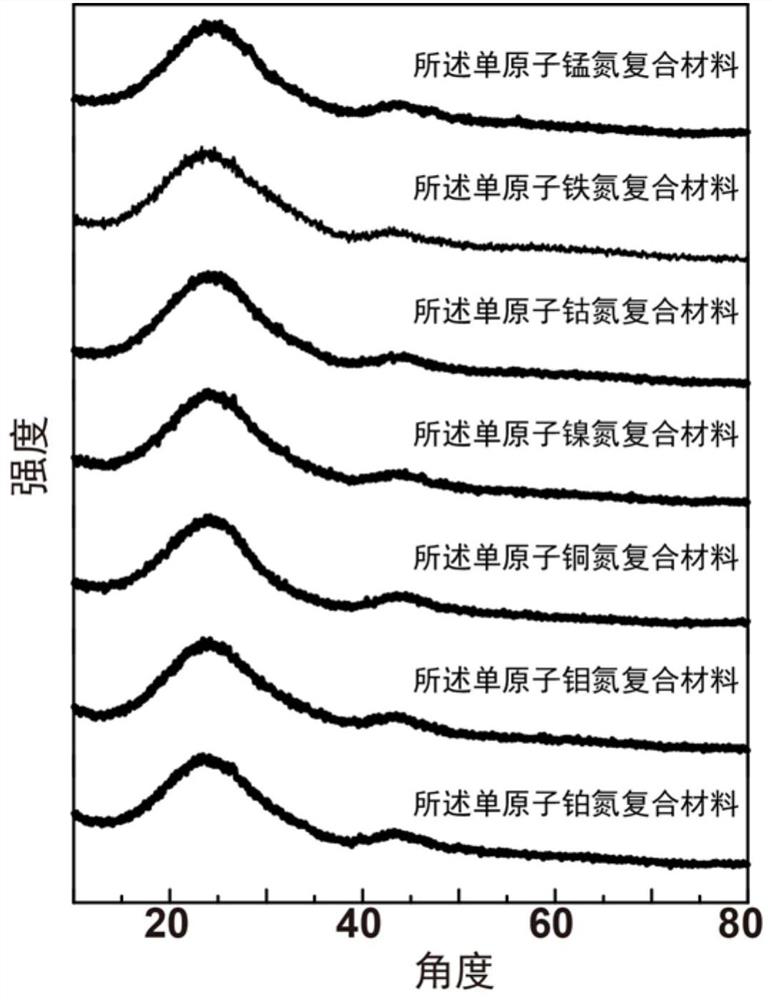

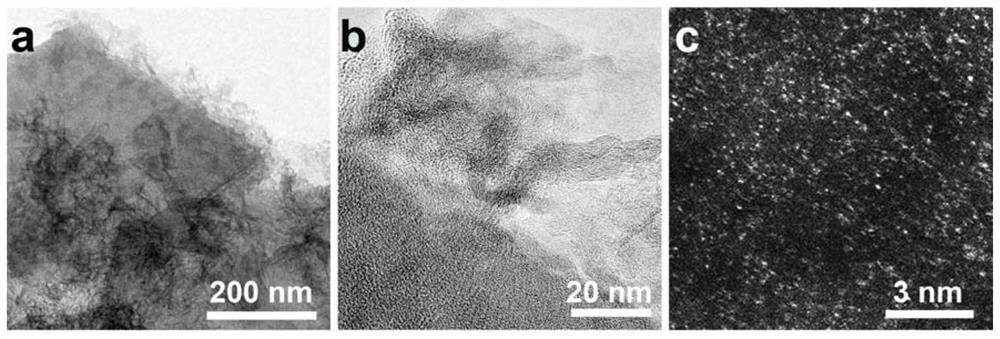

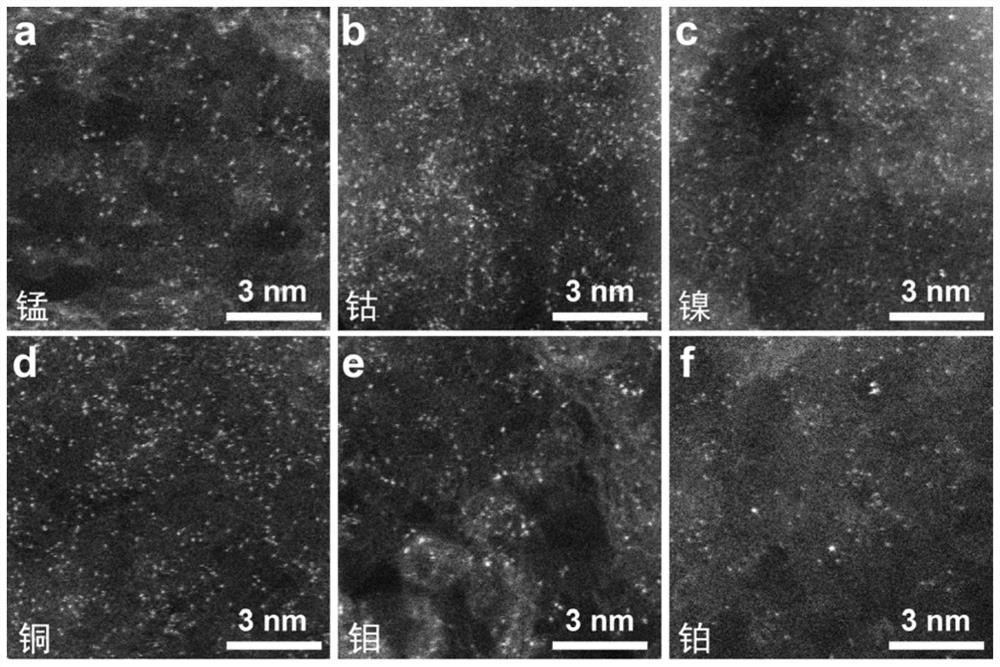

[0035] Example 1-7: Preparation of Porous Carbon Supported Single-atom Metal Nitrogen Coordination Composite Materials

Embodiment 1

[0036] Example 1 Preparation of porous carbon-supported single-atom iron-nitrogen coordination composites

[0037] (1) The Ketjen Black (model ECP-600JD, pore diameter of 0.5-20 nanometers, specific surface area of 1400 square meters per gram) purchased from Japan LION Company is 1:2 (porous carbon is 1:2) to iron nitrate mass ratio 60 mg, ferric nitrate is 120 mg) into 5 ml of deionized water, add glucose to 1.2 g, ultrasonically disperse evenly, let stand for adsorption for 24 hours, wash with water and centrifuge, and dry at 60°C for 24 hours at a vacuum of -0.1 MPa. Obtain about 200 mg of precursor;

[0038] (2) Grinding the precursor with melamine (mass ratio of precursor to melamine is 1:5) and transferring to the downstream of the double-temperature zone heating furnace (downstream along the direction of gas introduction); under the protection of inert gas , the downstream powder is heat-treated at 800°C for 2-4 hours, and then cooled to room temperature, and the p...

Embodiment 2

[0039] Example 2 Preparation of porous carbon-supported single-atom manganese-nitrogen coordination composites

[0040] Prepare the porous carbon-loaded manganese-nitrogen coordination composite material according to the same method as in Example 1, the difference is: the transition metal salt is manganese nitrate, and the mass ratio of porous carbon to manganese nitrate is 6:5 (60 mg of porous carbon, nitric acid 50 mg of manganese and 5 ml of deionized water).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com