Prefabricated runway and preparation process thereof

A preparation process and prefabricated technology, applied in the field of runways, can solve the problems of poor adhesion between the bottom layer of the runway and the top layer of the runway, affecting the normal use of the runway, and the separation of the surface layer and the bottom layer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

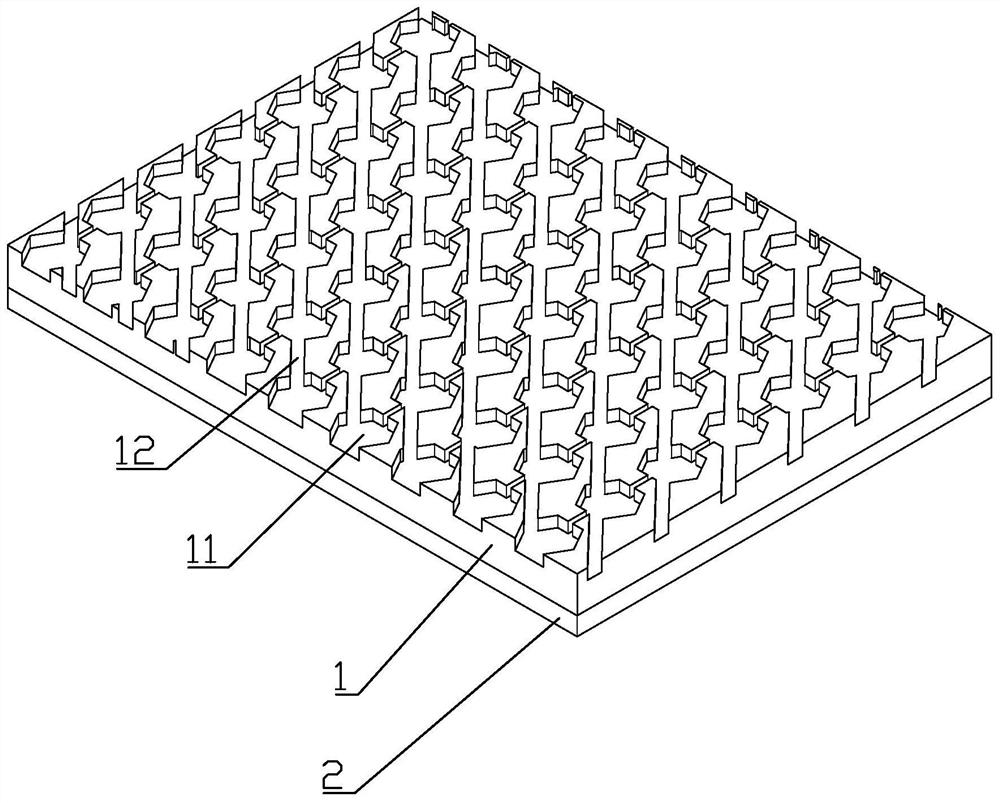

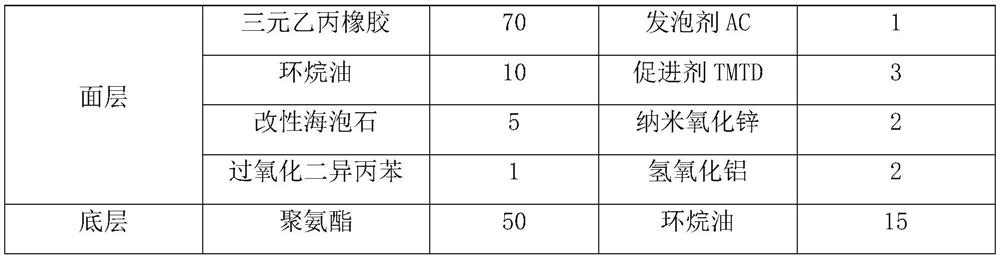

[0039]A prefabricated runway includes a surface layer 1 and a bottom layer 2, the surface layer 1 is made of foamed plastic, and the bottom layer 2 is made of polyurethane. Grooves 11 are evenly embossed on the surface layer 1 , and the cross section of the grooves 11 is a regular hexagon. Drainage ditch 12 is uniformly arranged on the surface layer 1 , and the drainage ditch 12 communicates with the groove 11 . The surface layer 1 is foamed plastic, and the surface layer 1 has a dense microfoam structure. On the one hand, the overall shock absorption effect of the runway is good, and on the other hand, it can save materials; the bottom layer 2 is polyurethane, which has excellent mechanical properties, such as resistance Grinding, high toughness, good elasticity at low temperature, etc. When it rains, the rainwater enters the groove 11 of the surface layer 1, and then is discharged through the gutter, so as to prevent the rainwater from accumulating in the surface layer 1, ca...

Embodiment 2

[0048] The structure of a prefabricated runway is the same as in Embodiment 1.

[0049] Each component and its quality of a kind of prefabricated runway of table 2 embodiment 2

[0050]

[0051] The preparation process of the prefabricated runway and the preparation method of the modified sepiolite are the same as in Example 1.

Embodiment 3

[0053] The structure of a prefabricated runway is the same as in Embodiment 1.

[0054] Each component and its quality of a kind of prefabricated runway of table 3 embodiment 3

[0055]

[0056]

[0057] The preparation process of the prefabricated runway specifically includes the following steps:

[0058] Step 1, weighing according to the weight of each component in the formula;

[0059] Step 2: Mix the components of the surface layer and the bottom layer uniformly in step 1, then melt and blend them on a twin-screw extruder, and extrude them into coils at a temperature of 180°C .

[0060] The preparation method of modified sepiolite is as follows: first, add sepiolite into toluene solution and stir, then mix γ-methacryloxypropylmethyldimethoxysilane and absolute ethanol evenly, then add to the Continue stirring in the toluene solution of stone; then the mixed solution is filtered, washed, dried and ball milled to obtain modified sepiolite powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com