Structure of gapless laminated film capacitor

A film capacitor, gapless technology, applied in the direction of film/thick film capacitors, multilayer capacitors, fixed capacitor electrodes, etc., can solve problems such as affecting energy storage density and affecting high frequency characteristics of capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

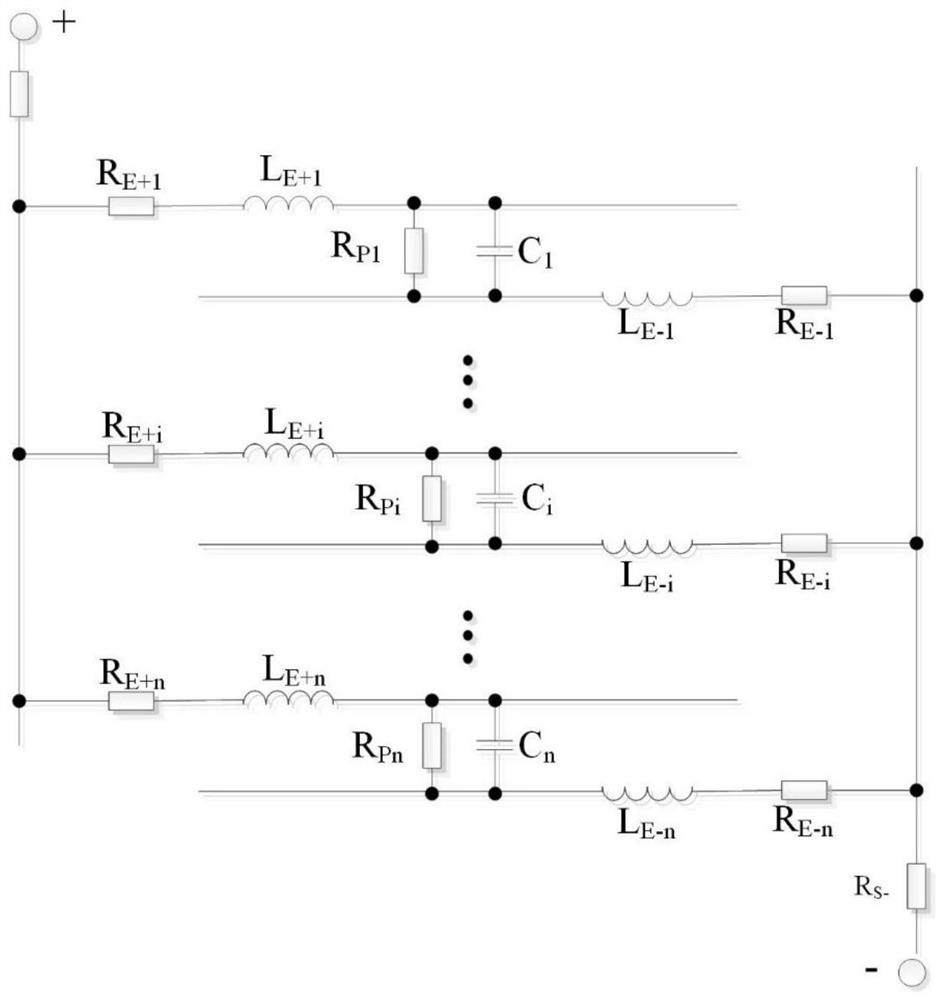

[0018] The working principle and implementation method of the present invention will be further described in detail below in conjunction with the accompanying drawings.

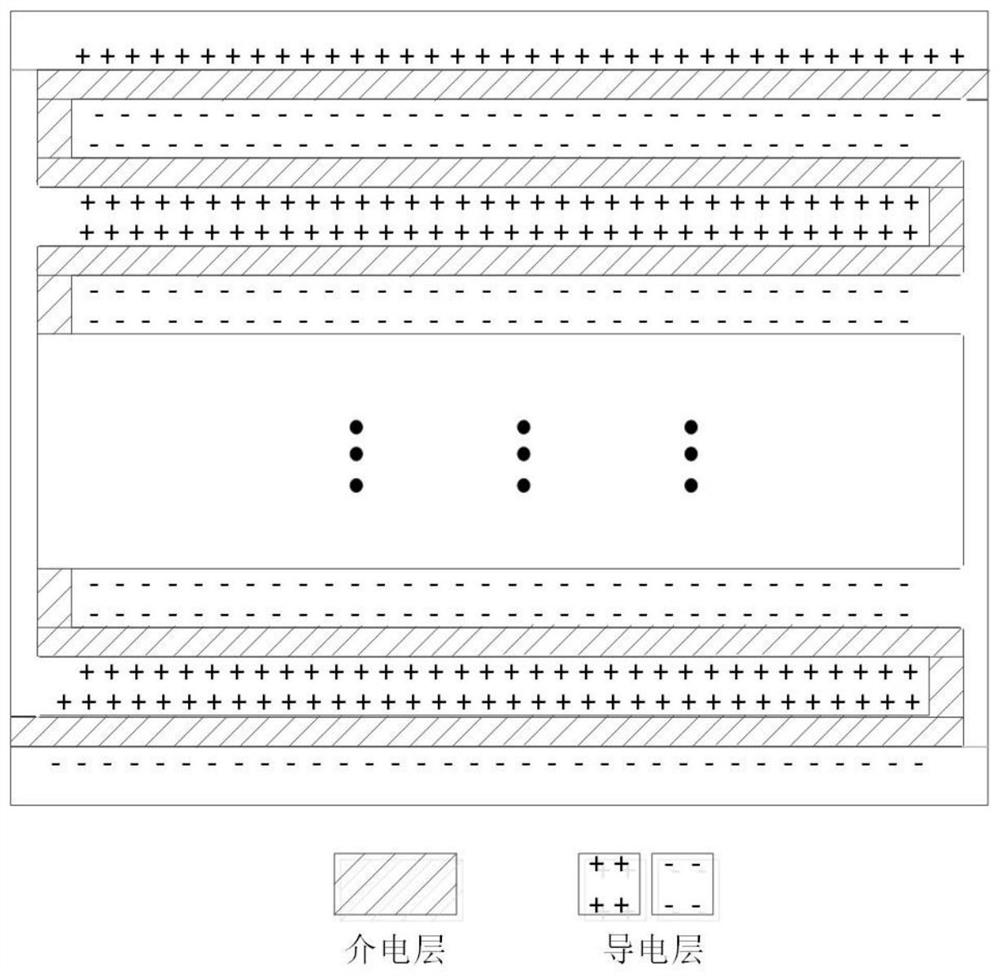

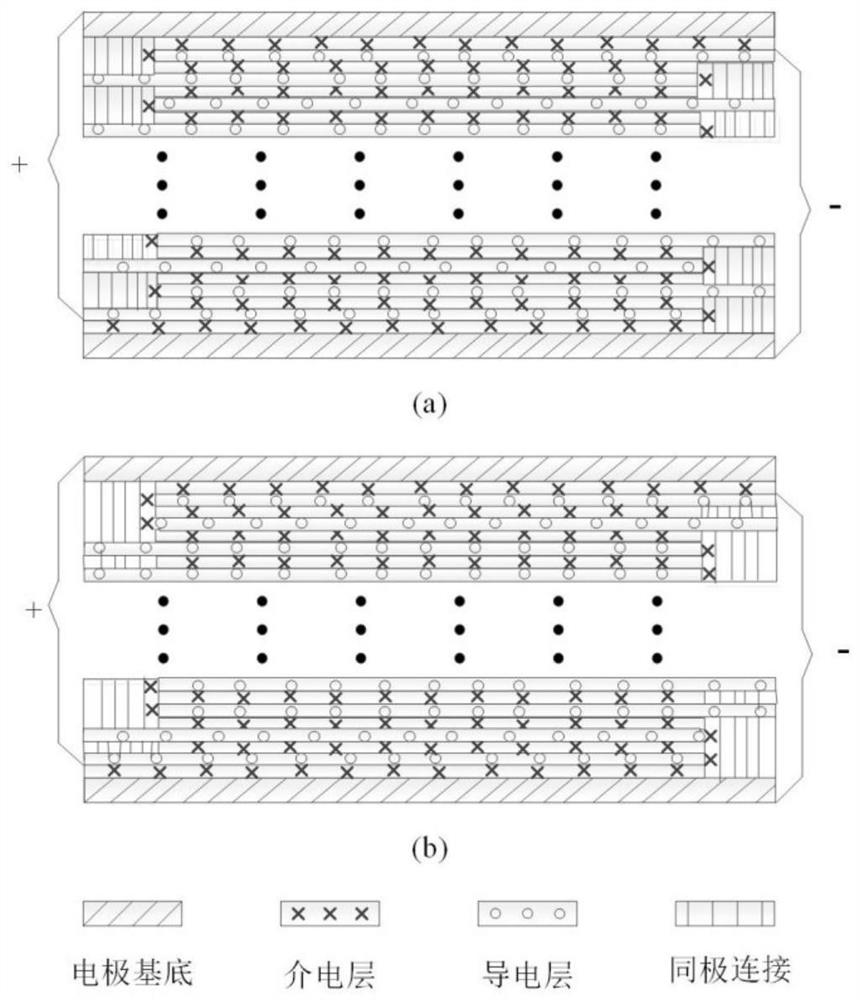

[0019] In an environment protected by argon, a layer of metal aluminum is sprayed on the surface of the aluminum base material by the electric explosion wire spraying method; then the sample is placed in an oxygen (nitrogen) environment and oxidized (nitrided) at a high temperature to form a layer of oxide Aluminum (aluminum nitride) dielectric layer; then repeat the above steps, and finally make the following figure 1 In the gapless stacked thin film structure shown, a thin film capacitor can be prepared by leading out positive and negative electrodes respectively.

[0020] when to give figure 1 When the film capacitor shown is charged, the positive and negative electrodes of the capacitor are charged with positive and negative charges respectively, with a dielectric layer between the electrodes. It is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com