Preparation method of edible blend oil

A technology for blending oil and lard, which is applied in the directions of edible oil/fat, chemical instruments and methods, and applications, etc., can solve the problems of filter screen blockage, easy oxidation, and high acid value, and achieves prevention of oxidation, strong anti-oxidation, and promotion of regeneration. and growth effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of edible blended oil is characterized in that it comprises the following steps:

[0036] Step 1: Weigh 60 parts of sunflower oil, 10 parts of linseed oil, 2 parts of safflower seed oil, 1 part of grape seed oil, 0.2 parts of fish oil, 2 parts of wheat germ oil, 1 part of peanut oil, pig 5 parts of oil, 0.1 part of olive oil, 10 parts of soybean oil, 0.5 part of lycopene, 0.2 part of butylated hydroxyanisole, 1 part of tocopherol, 2 parts of sodium citrate, 0.5 part of cyclohexanol phosphate, admixture 10 copies;

[0037] Step 2: Put sunflower oil, linseed oil, safflower seed oil, grape seed oil, fish oil, wheat germ oil, peanut oil, olive oil, soybean oil, and admixtures into a premixer and mix to obtain a mixture;

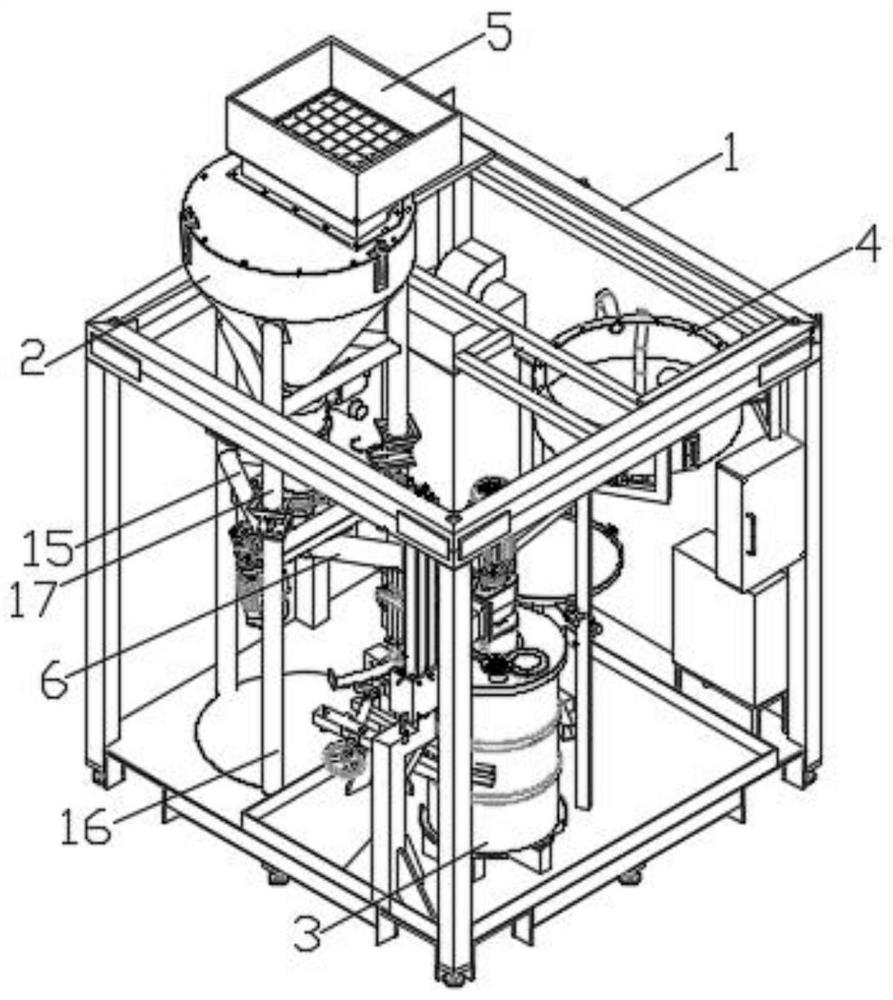

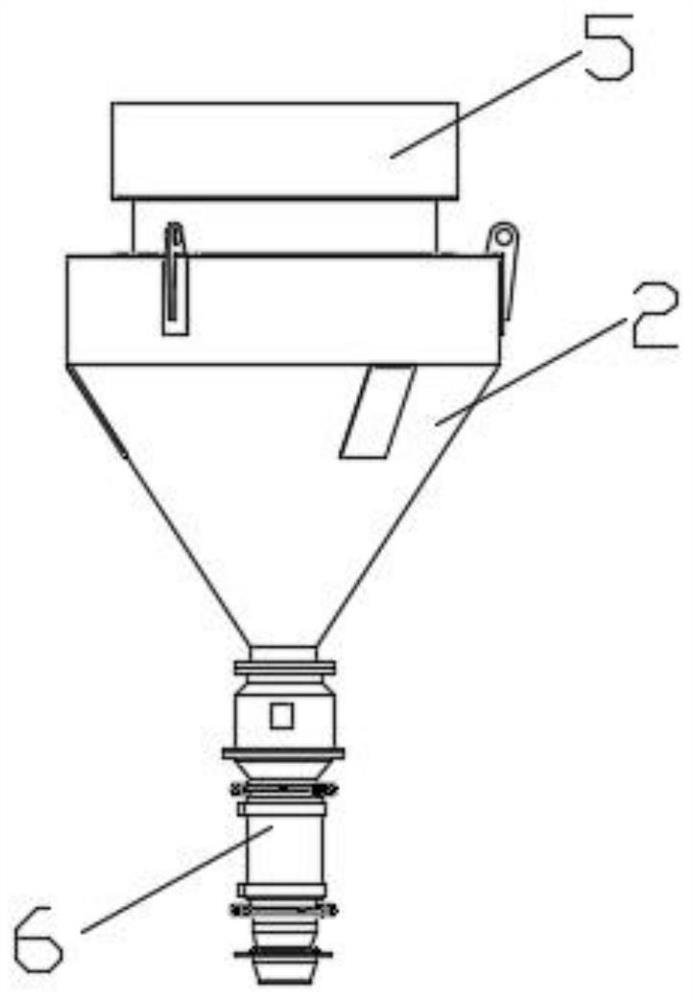

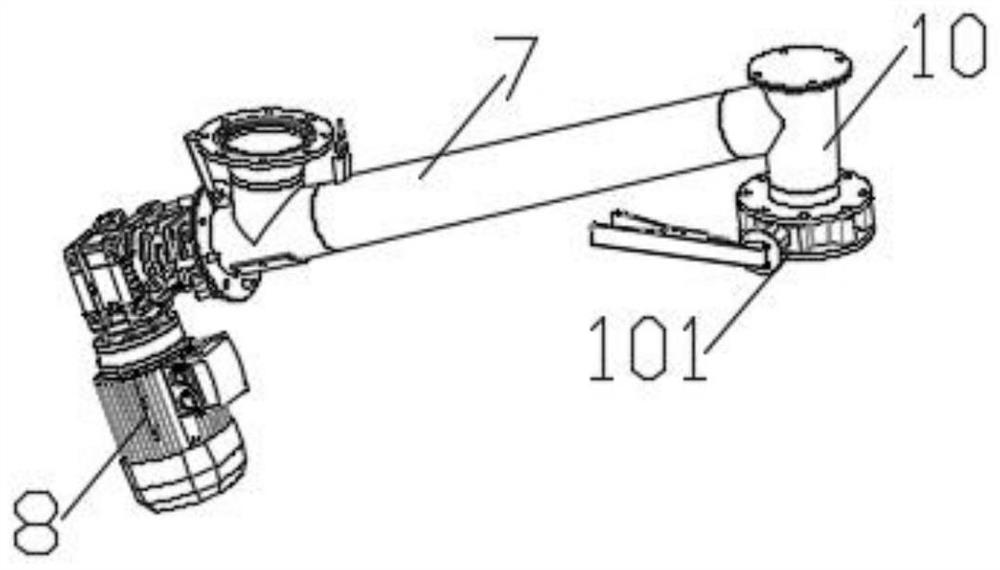

[0038] Step 3: Step 3: Put the lard into the heating shell 5 of the processing equipment. The electric heating net in the heating shell 5 heats and melts the lard. The melted lard enters the first hopper 2 and turns on the first The motor 8...

Embodiment 2

[0043] A preparation method of edible blended oil is characterized in that it comprises the following steps:

[0044] Step 1: According to parts by weight, weigh out 70 parts of sunflower oil, 12 parts of linseed oil, 3 parts of safflower seed oil, 3 parts of grape seed oil, 0.5 parts of fish oil, 3 parts of wheat germ oil, 2 parts of peanut oil, pig 5.5 parts of oil, 0.2 parts of olive oil, 12 parts of soybean oil, 0.8 parts of lycopene, 0.3 parts of butylated hydroxyanisole, 2 parts of tocopherol, 3 parts of sodium citrate, 0.7 parts of cyclohexanol phosphate, admixtures 12 copies;

[0045] Step 2: Put sunflower oil, linseed oil, safflower seed oil, grape seed oil, fish oil, wheat germ oil, peanut oil, olive oil, soybean oil, and admixtures into a premixer and mix to obtain a mixture;

[0046] Step three is the same as embodiment 1;

[0047] Step 4: Add lycopene, butylated hydroxyanisole, tocopherol, sodium citrate, cyclohexanol phosphate, admixtures to the mixed blending oil, mix ...

Embodiment 3

[0051] A preparation method of edible blended oil includes the following steps:

[0052] Step 1: According to parts by weight, weigh out 90 parts of sunflower oil, 20 parts of linseed oil, 6 parts of safflower seed oil, 8 parts of grape seed oil, 1.2 parts of fish oil, 5 parts of wheat germ oil, 5 parts of peanut oil, pig 7 parts of oil, 0.5 parts of olive oil, 25 parts of soybean oil, 1.2 parts of lycopene, 0.6 parts of butylated hydroxyanisole, 4 parts of tocopherol, 4 parts of sodium citrate, 1.2 parts of cyclohexanol phosphate, admixtures 15 copies;

[0053] Step 2: Put sunflower oil, linseed oil, safflower seed oil, grape seed oil, fish oil, wheat germ oil, peanut oil, olive oil, soybean oil, and admixtures into a premixer and mix to obtain a mixture;

[0054] Step three is the same as embodiment 1;

[0055] Step 4: Add lycopene, butylated hydroxyanisole, tocopherol, sodium citrate, cyclohexanol phosphate, and admixtures to the mixed blending oil, mix them thoroughly, oscillate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com