Biological preparation for treating diarrhea of pets

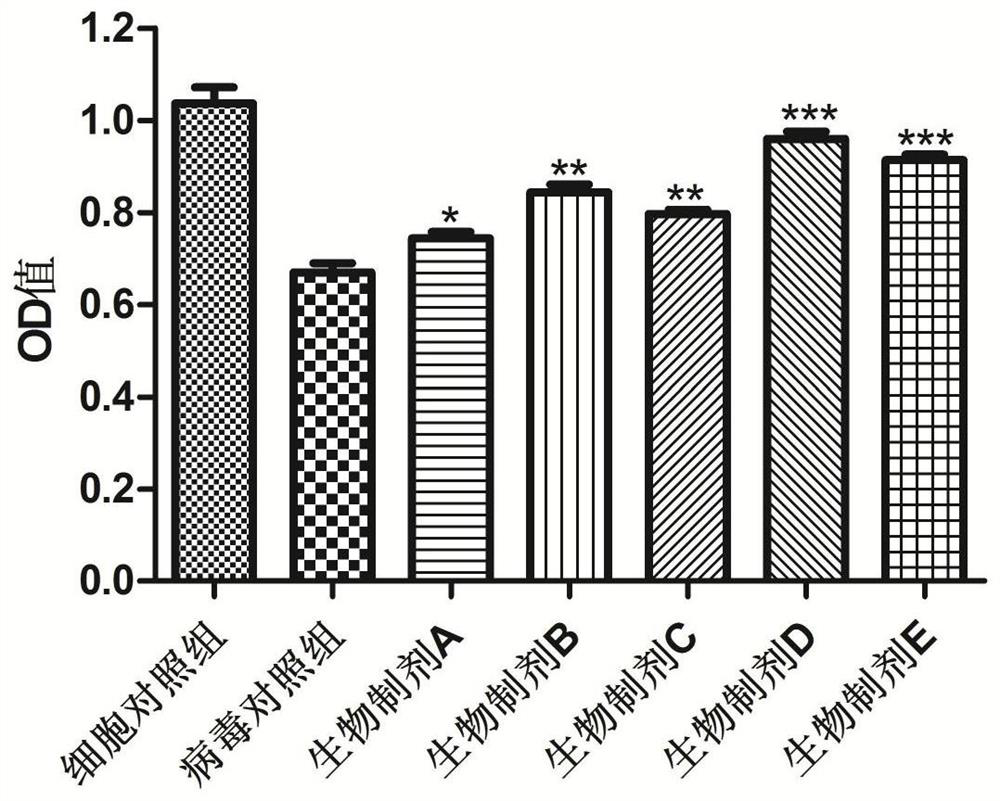

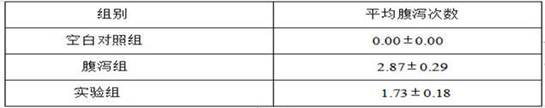

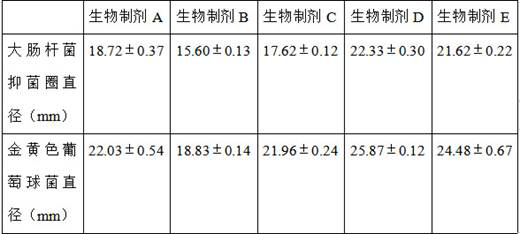

A biological agent and diarrhea technology, applied in the field of veterinary medicine, can solve problems such as drug residues and bacterial drug resistance, achieve inhibition of Escherichia coli and Staphylococcus aureus, reduce diarrhea frequency and loose stool rate, and inhibit canine parvovirus Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Wash 500g of dried cicadae, dry it in a dryer, and crush it with a grinder;

[0046] (2) Add 10L of water and ultrasonically break for 120min;

[0047] (3) Centrifuge at 3000rpm / min for 30min, remove the precipitate, keep the supernatant, and obtain the crude polysaccharide extract;

[0048] (4) Evaporate the crude polysaccharide extract at 70°C under reduced pressure to 1L to obtain the crude polysaccharide concentrate;

[0049] (5) Adjust the crude polysaccharide concentrate to 37°C, the pH value is 8, add 100g trypsin, and enzymatically hydrolyze for 1.5h;

[0050] (6) Adjust the temperature to 95°C, inactivate for 20 minutes, add 3 times the amount of 85% ethanol, and overnight at 4°C;

[0051] (7) Centrifuge at 3000rpm / min for 30min, remove the supernatant, and freeze-dry the precipitate to obtain Cicada polysaccharide.

Embodiment 2

[0053] (1) Wash 500g of dried motherwort, dry it in a dryer, and crush it with a grinder;

[0054] (2) Add 10L of water and ultrasonically break for 120min;

[0055] (3) Centrifuge at 3000rpm / min for 30min, remove the precipitate, keep the supernatant, and obtain the crude polysaccharide extract;

[0056] (4) Evaporate the crude polysaccharide extract at 70°C under reduced pressure to 1L to obtain the crude polysaccharide concentrate;

[0057] (5) Adjust the crude polysaccharide concentrate to 37°C, the pH value is 8, add 100g of trypsin, and enzymatically hydrolyze for 1.5h;

[0058] (6) Adjust the temperature to 95°C, inactivate for 20 minutes, add 3 times the amount of 85% ethanol, and overnight at 4°C;

[0059] (7) Centrifuge at 3000rpm / min for 30min, remove the supernatant, precipitate and freeze-dry to obtain Motherwort polysaccharide.

Embodiment 3

[0061] (1) Clean 500g of chrysanthemum starfish, dry it in a dryer, place it in a grinder, add liquid nitrogen and grind it into powder to obtain chrysanthemum starfish powder;

[0062] (2) Add the chrysanthemum star powder to 1.5kg of water, stir until completely dissolved, and obtain a homogenate of chrysanthemum starfish;

[0063] (3) Adjust the temperature of Chrysanthemum starfish homogenate to 50°C, pH to 6, add 100g of papain, and enzymatically hydrolyze for 1.5h;

[0064] (4) Adjust the temperature to 95°C, inactivate for 20 minutes, cool to room temperature, centrifuge at 3500 rpm / min for 30 minutes, collect the supernatant, and obtain the crude polypeptide extract;

[0065] (5) After passing the crude polypeptide through a nanofiltration membrane with a pore size of 2 nm, freeze-drying to obtain the chrysanthemum starfish polypeptide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com