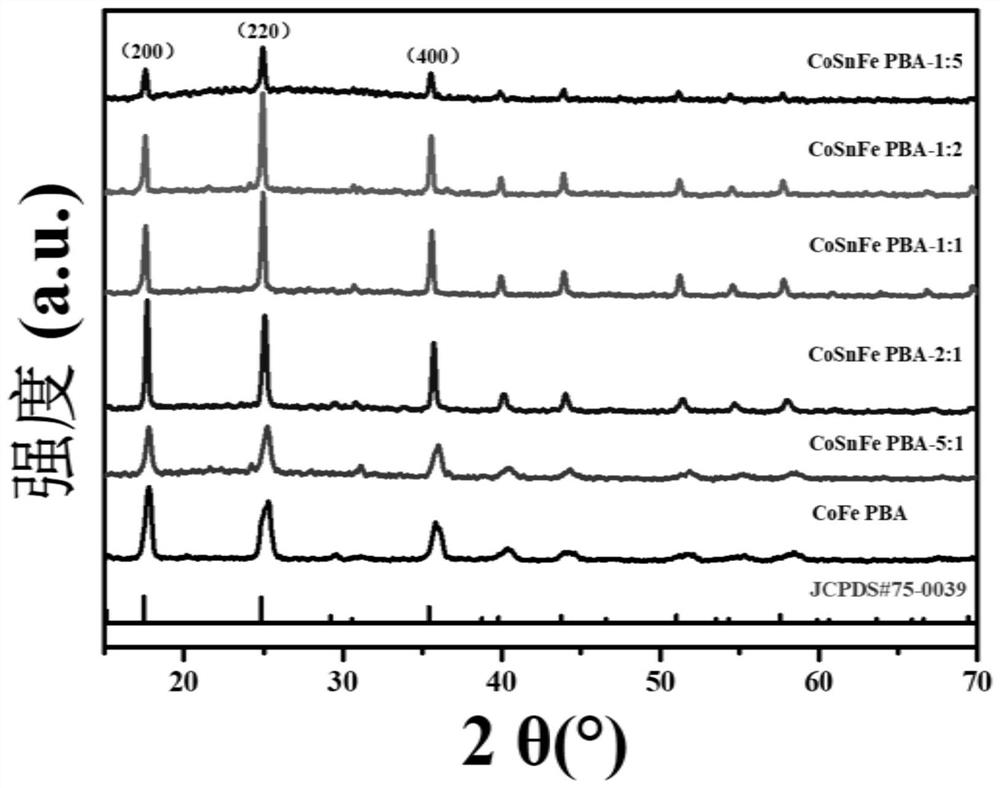

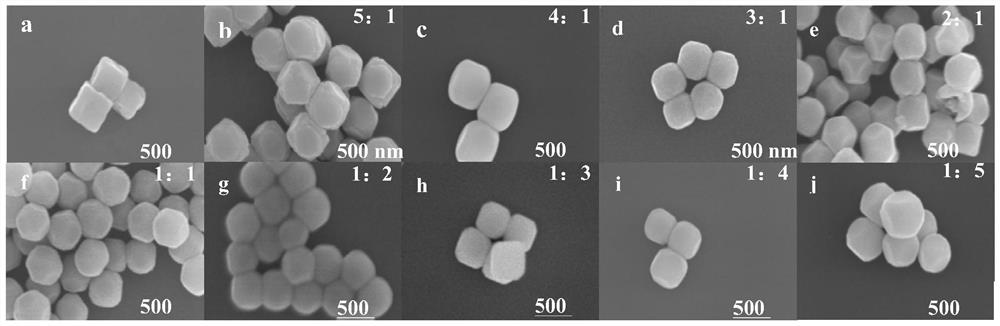

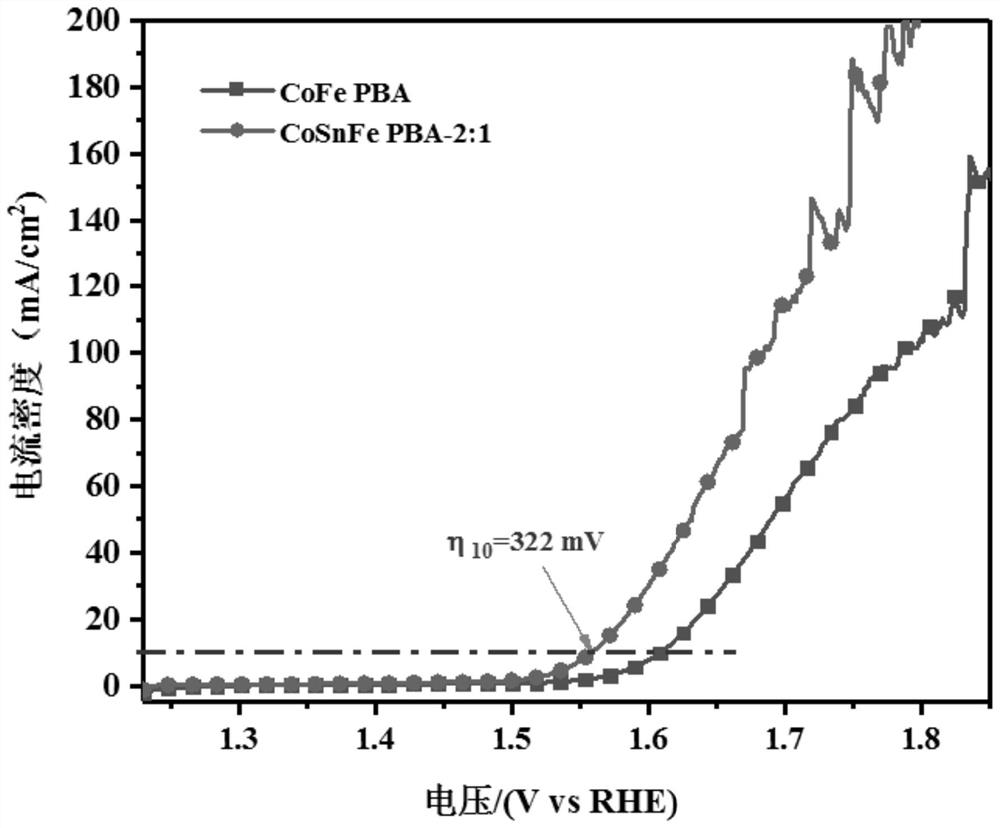

Anode catalyst for electrolyzing water and preparation method thereof

A technology of catalyst and electrolysis of water, applied in the field of electrocatalysis, to achieve the effect of improving catalytic activity, excellent electrocatalytic oxygen production performance, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Dissolve 95.172mg of cobalt chloride hexahydrate, 45.126mg of stannous chloride and 264.69mg of sodium citrate dihydrate in 20mL of deionized water, add 20mL of potassium ferricyanide aqueous solution while stirring to obtain a mixed solution, and let it stand for 48h , the product was centrifuged, washed, and vacuum-dried for 24 hours to obtain CoSnFePBA-2:1.

Embodiment 2

[0031] Dissolve 142.758mg of cobalt chloride hexahydrate, 45.126mg of stannous chloride and 264.69mg of sodium citrate dihydrate in 20mL of deionized water, add 20mL of potassium ferricyanide aqueous solution while stirring to obtain a mixed solution, and let it stand for 24h , the product was centrifuged, washed, and vacuum-dried for 24 hours to obtain CoSnFePBA-5:1.

Embodiment 3

[0033] Dissolve 114.2064mg of cobalt chloride hexahydrate, 27.0756mg of stannous chloride and 264.69mg of sodium citrate dihydrate in 20mL of deionized water, add 20mL of potassium ferricyanide aqueous solution while stirring to obtain a mixed solution, and let it stand for 48h , the product was centrifuged, washed, and vacuum-dried for 24 hours to obtain CoSnFePBA-4:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com