Device for separating roasting material through air-cooling regulation and control magnetic reinforcement and recycling latent heat

A technology for roasting materials and materials, which is applied in the direction of devices whose axial direction can be reversed, magnetic separation, and swirl devices, etc., which can solve problems such as high energy consumption and magnetic agglomeration of products, and achieve high heat transfer efficiency and reduce Magnetic agglomeration, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

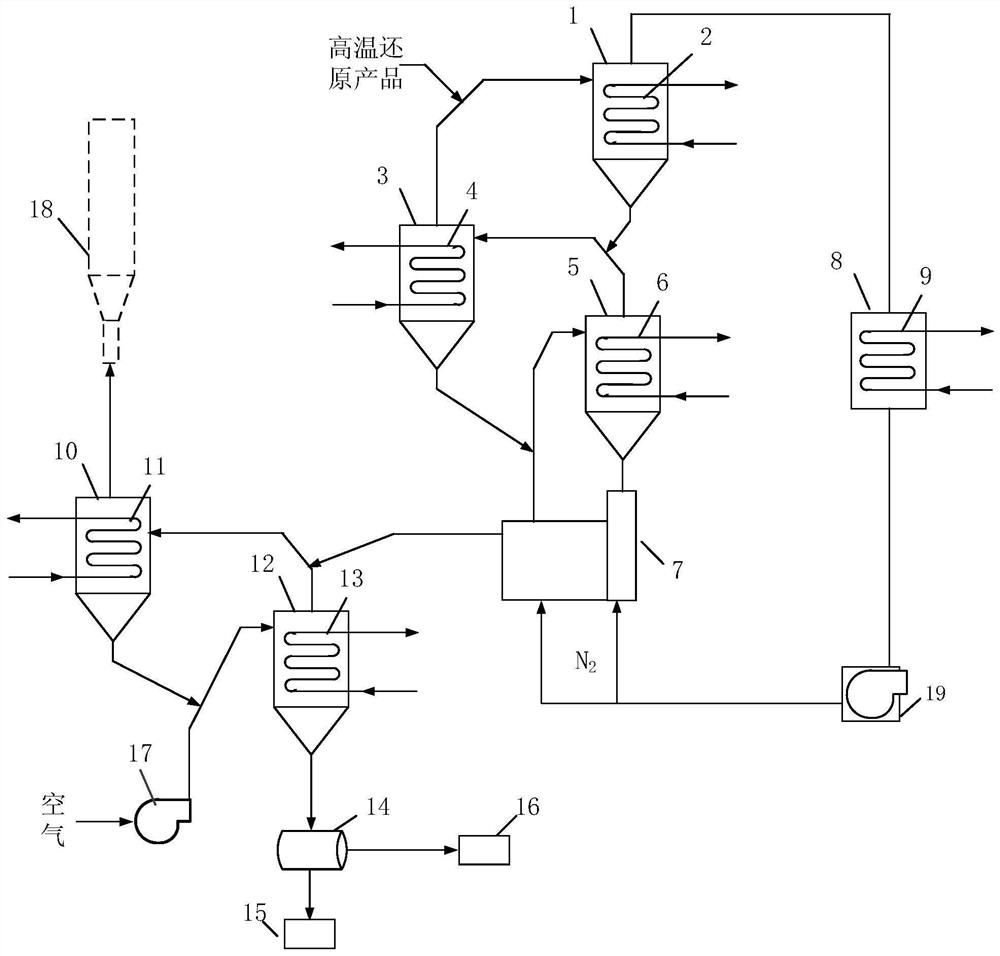

[0051] The structure of the device for air-cooling the roasted material to regulate magnetically enhanced separation and recover latent heat is as follows: figure 1 Shown, comprise nitrogen cooling cyclone separator group, flow sealing valve (7), air cooling cyclone separator group and magnetic separator (14);

[0052] The nitrogen cooling cyclone separator group is composed of 3 stages of nitrogen cooling cyclone separators, the outlet of the first stage nitrogen cooling cyclone separator (1) is connected with the inlet of the second stage nitrogen cooling cyclone separator (3), the second stage of nitrogen cooling cyclone separator (3) The gas outlet of the second-stage nitrogen-cooled cyclone separator (3) is connected with the inlet of the first-stage nitrogen-cooled cyclone separator (1), and the outlet of the second-stage nitrogen-cooled cyclone separator (3) is connected with the inlet of the third-stage nitrogen-cooled cyclone separator. The feed inlet of the nitrogen ...

Embodiment 2

[0070] Device structure is the same as embodiment 1;

[0071] Method is with embodiment 1, and difference is:

[0072] (1) The particle size of the roasted material -0.074mm accounts for 70% of the total mass, and the temperature of the roasted material is 550°C. The Fe content of magnetite in the roasted material accounts for 96% of the total Fe in the reduced roasted material; complex refractory ore iron Grade TFe 30.28%, containing SiO by mass percentage 2 29.21%;

[0073] (2) The roasted material is cooled to 260° C. in the nitrogen-cooled cyclone group; the residence time of the reduced roasted material in the nitrogen-cooled cyclone group is 15 minutes;

[0074] (3) The residence time of the cooling roasting material in the air cooling cyclone separator group is 8min;

[0075] (4) The magnetic field strength of weak magnetic separation is 1300Oe, obtains iron ore concentrate, iron grade TFe 57.93%; The rate of recovery of Fe is 86.52%; Compared with the weak magnetic...

Embodiment 3

[0077] Device structure is the same as embodiment 1;

[0078] Method is with embodiment 1, and difference is:

[0079] (1) Particle diameter -0.074mm of the roasted material accounts for 80% of the total mass, and the temperature of the roasted material is 510°C. The Fe content of magnetite in the roasted material accounts for 94% of the total Fe in the reduced roasted material; complex refractory ore iron Grade TFe 42.19%, containing SiO by mass percentage 2 50.67%;

[0080] (2) The roasted material is cooled to 280°C in the nitrogen-cooled cyclone group; the residence time of the reduced roasted material in the nitrogen-cooled cyclone group is 17 minutes;

[0081] (3) The residence time of the cooling roasting material in the air-cooling cyclone separator group is 5min;

[0082] (4) The magnetic field intensity of weak magnetic separation is 1700Oe, obtains iron ore concentrate, iron grade TFe58.26%; The rate of recovery of Fe is 85.4%; Compared with the weak magnetic or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com