Diamond wire for cutting large-size photovoltaic silicon wafer and manufacturing method thereof

A manufacturing method and diamond wire technology, applied in the direction of manufacturing tools, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as increased TTV defect ratio, reduce the probability of micro-powder adhesion and agglomeration, improve performance, and increase toughness and strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

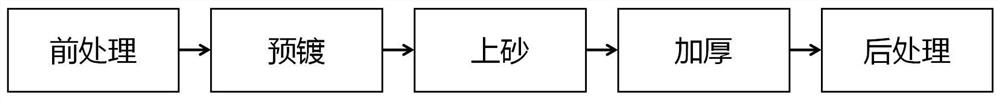

[0049] like figure 1As shown, this embodiment provides a manufacturing method of diamond wire for cutting photovoltaic large-size silicon wafers, which includes the following steps: (1) pretreatment, processing the diamond fine powder and the busbar; (2) preplating, electroplating on the surface of the busbar A layer of nickel coating; (3) Sanding, using the principle of composite electroplating to fix the diamond powder on the busbar; (4) Thickening, continue to electroplate the nickel coating to make the diamond powder firmly fixed; (5) After treatment, the diamond powder made of Line for cleaning and aging treatment.

[0050] Wherein, in step (1), the diamond micropowder is treated by modifying the diamond micropowder, which can improve the sand-loading ability of the diamond micropowder and reduce the adhesion and agglomeration probability of the diamond micropowder. The specific treatment method includes: first, put the diamond micro-powder coated with a high-phosphorus ...

Embodiment 2

[0058] like figure 1 As shown, this embodiment provides a manufacturing method of diamond wire for cutting photovoltaic large-size silicon wafers, which includes the following steps: (1) pretreatment, processing the diamond fine powder and the busbar; (2) preplating, electroplating on the surface of the busbar A layer of nickel coating; (3) Sanding, using the principle of composite electroplating to fix the diamond powder on the busbar; (4) Thickening, continue to electroplate the nickel coating to make the diamond powder firmly fixed; (5) After treatment, the diamond powder made of Line for cleaning and aging treatment.

[0059] Wherein, in step (1), the diamond micropowder is treated by modifying the diamond micropowder, which can improve the sand-loading ability of the diamond micropowder and reduce the adhesion and agglomeration probability of the diamond micropowder. The specific treatment method includes: first, put the diamond micro-powder coated with a high-phosphorus...

Embodiment 3

[0067] like figure 1 As shown, this embodiment provides a manufacturing method of diamond wire for cutting photovoltaic large-size silicon wafers, which includes the following steps: (1) pretreatment, processing the diamond fine powder and the busbar; (2) preplating, electroplating on the surface of the busbar A layer of nickel coating; (3) Sanding, using the principle of composite electroplating to fix the diamond powder on the busbar; (4) Thickening, continue to electroplate the nickel coating to make the diamond powder firmly fixed; (5) After treatment, the diamond powder made of Line for cleaning and aging treatment.

[0068] Wherein, in step (1), the diamond micropowder is treated by modifying the diamond micropowder, which can improve the sand-loading ability of the diamond micropowder and reduce the adhesion and agglomeration probability of the diamond micropowder. The specific treatment method includes: first, put the diamond micro-powder coated with a high-phosphorus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com